Ink composition, and production method of electroluminescent device

A composition and ink technology, applied in electrical components, semiconductor devices, inks, etc., can solve problems such as uneven nanoparticle layers, and achieve the effect of reducing the phenomenon of coffee rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

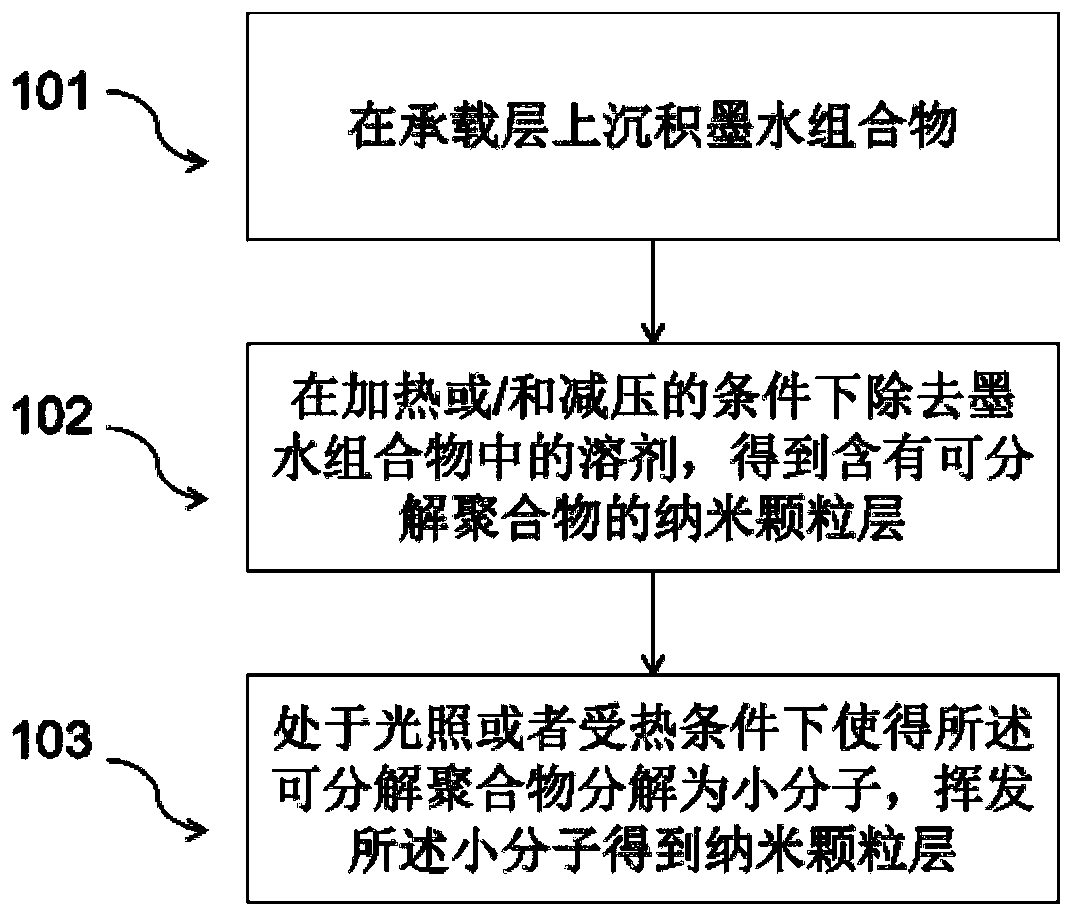

[0027] like figure 1 As shown in the flow chart of the present application, the preparation method of the electroluminescent device includes the following process of preparing the nanoparticle layer, including step 101 depositing the ink composition on the carrier layer; step 102 under the conditions of heating or / and decompression Removing the solvent in the ink composition to obtain a nanoparticle layer containing a decomposable polymer; step 103 decomposes the decomposable polymer into small molecules under light or heat conditions, and volatilizes the small molecules to obtain a nanoparticle layer.

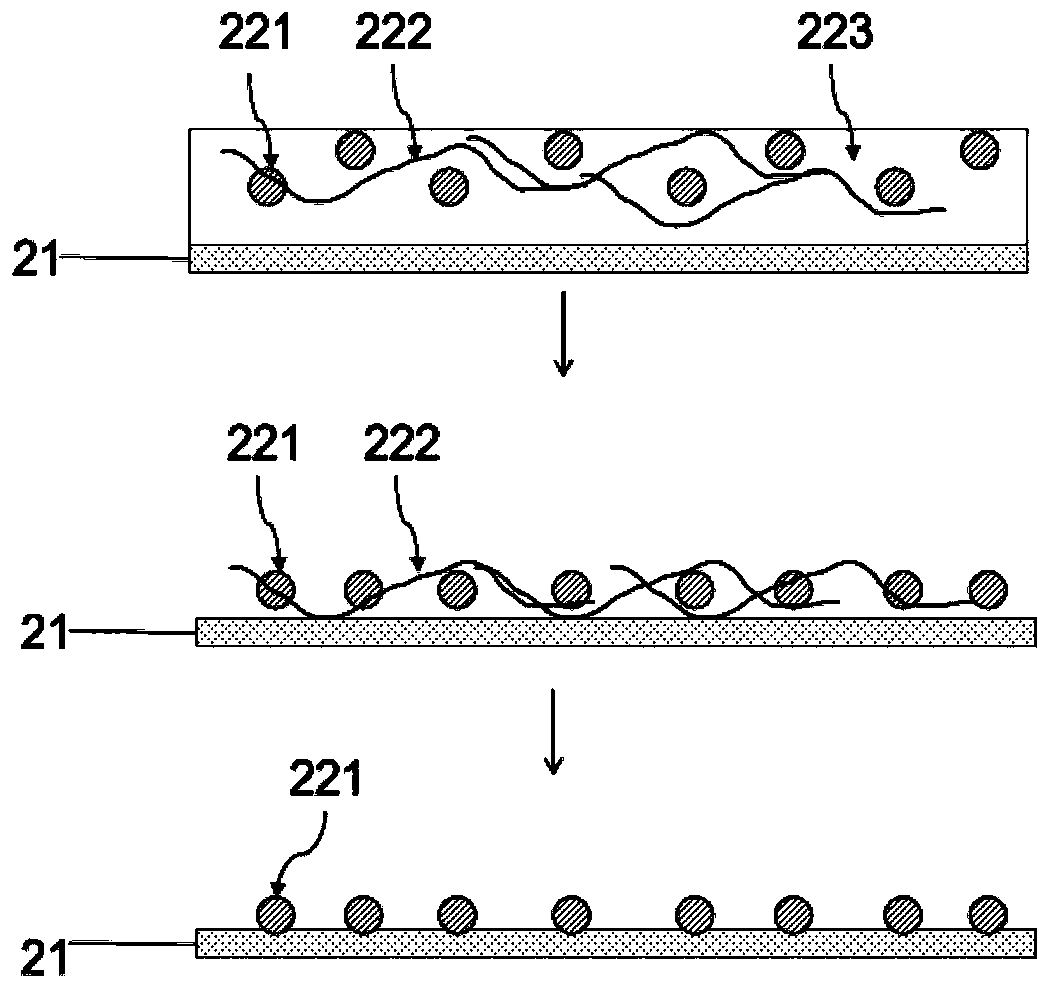

[0028] In step 101, the schematic diagram of depositing the ink composition on the carrier layer is shown in figure 2 , including a carrier layer 21 and an ink composition layer, where the ink composition layer includes nanoparticles 221 , a decomposable polymer 222 and a solvent 223 .

[0029] In step 102, after the solvent is removed from the ink composition layer, continu...

Embodiment 1

[0032] An ink composition is provided, comprising: nickel oxide nanoparticles with 1wt% nanoparticles, 43.8wt% ethylene glycol and 55wt% ethylene glycol butyl ether as a solvent, and a weight average molecular weight of 0.2wt% decomposable polymer About 2000 polyethylene carbonate. The viscosity of the above ink composition is about 3.1 mPa.s.

[0033] Adopt above-mentioned ink composition to prepare the hole transporting layer of electroluminescent device, specific process is as follows: On carrying layer (ITO anode layer), ink-jet printing above-mentioned ink composition, in vacuum chamber, under the pressure of 5Pa and normal temperature, remove The solvent is then heated to 100 degrees Celsius while maintaining a pressure of 5 Pa to remove the decomposable polymer and obtain a nanoparticle layer. The nanoparticle layer was evenly formed into a film, and no obvious coffee ring phenomenon was observed.

Embodiment 2

[0035] An ink composition is provided, comprising: nanoparticles are 5wt% zinc oxide nanoparticles, a solvent is 58wt% diethylene glycol butyl ether and 35wt% ethylene glycol, and a decomposable polymer has a weight average molecular weight of 2wt%. About 5000 polypropylene carbonate. The viscosity of the above ink composition is about 8.5 mPa.s.

[0036] Adopt above-mentioned ink composition to prepare the electron transport layer of electroluminescence device, specific process is as follows: Ink-jet printing above-mentioned ink composition on carrying layer (quantum dot light-emitting layer), in vacuum box, under the pressure of 100Pa and normal temperature, remove solvent , and then maintain the pressure of 100Pa and raise the temperature to 80°C to remove the decomposable polymer to obtain a nanoparticle layer. The nanoparticle layer was evenly formed into a film, and no obvious coffee ring phenomenon was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com