Preparation method of cefadroxil

A technology for cefadroxil and fadroxil, which is applied in the field of medicine and can solve the problems of the decrease in the catalytic activity of penicillin acylase, the harm to the ecological environment caused by the volatile organic solvent, and the low yield of the target product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

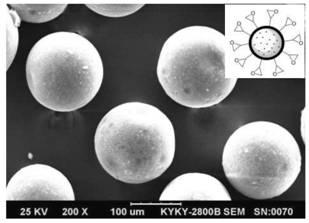

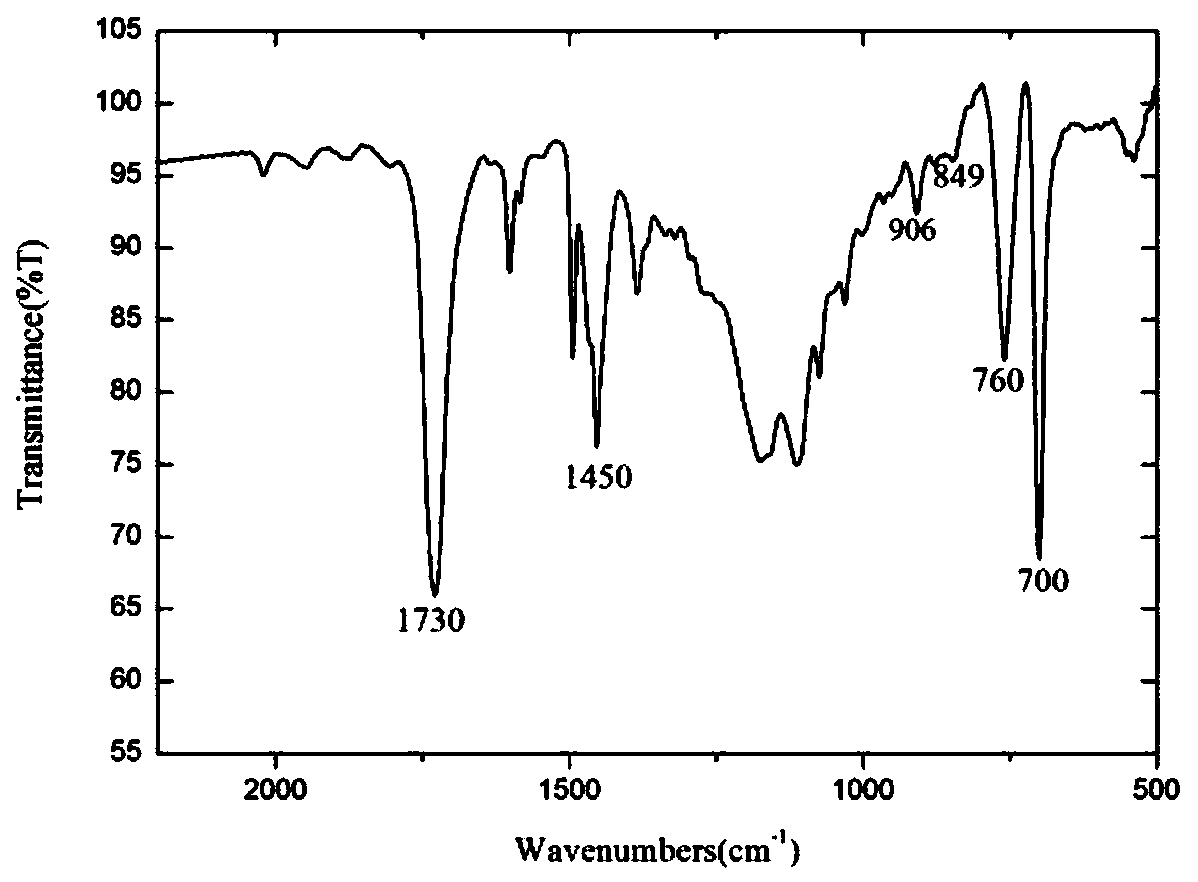

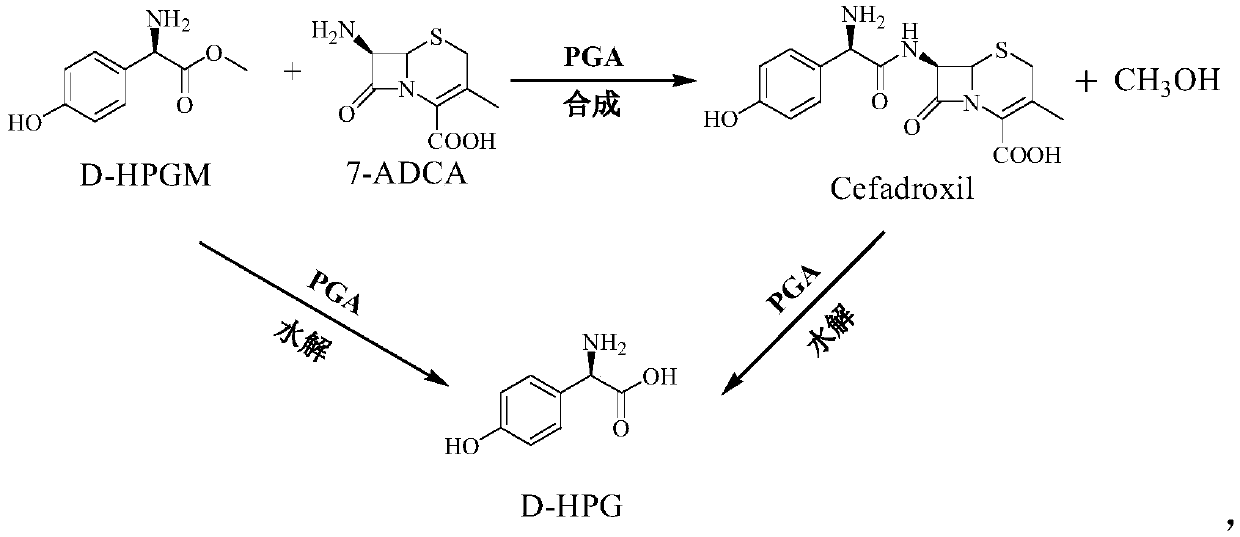

[0028] The method for preparing cefadroxil provided by the present invention includes the following steps: adding a predetermined volume of ionic liquid and a phosphate buffer solution to form a co-solvent in a water bath thermostat; adding a predetermined molar ratio of D to the co-solvent -HPGM and 7-ADCA are stirred and the molar ratio of D-HPGM to 7-ADCA is 1:1~1:2.0; the concentration of 7-ADCA is 0.1~1.0 mol / L; D-HPGM and 7-ADCA are added to Add magnetic immobilized penicillin G acylase to the ADCA co-solvent, and the mass ratio of magnetic immobilized penicillin G acylase to 7-ADCA is 1:10~1:50. Continue stirring to make the magnetic immobilized penicillin G acylase Fully contact with D-HPGM and 7-ADCA until the end of the reaction, where the stirring speed is controlled to be 150-250r / min; the reaction system liquid at the end of the reaction is allowed to stand in layers to make the upper phosphate buffer with cefadroxil dissolved The solution is layered with the lower...

Embodiment 1

[0036] Example 1. Add 60 mL of ionic liquid 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt and 40 mL of sodium phosphate buffer solution (0.10mol / L, pH 7.0) into the reactor, and mix well. Add 0.1mol 7-ADCA and 0.15molD-HPGM, at this time the concentration of 7-ADCA is 214g / L. Then add 0.42g magnetic immobilized penicillin G acylase, at this time the mass ratio of immobilized enzyme to 7-ADCA is 1:50, the temperature of the water bath is controlled at 30℃, the stirring speed is controlled to 150r / min, the reaction is 10 hours, magnetic force The immobilized enzyme is isolated under the action. Adjust the pH value of the upper layer solution of the separated reaction system to 5.2, and obtain cefadroxil crystals by crystallization. The reactor can be a batch reactor commonly used in industry.

Embodiment 2

[0037] In Example 2, 60mL of ionic liquid 1-butyl-3-methylimidazole hexafluorophosphate and 40mL of sodium phosphate buffer solution (0.10mol / L, pH 7.0) were added to the reactor, and 0.1mol 7- ADCA and 0.15mol D-HPGM, at this time the concentration of 7-ADCA is 214g / L. Then add 0.42g magnetic immobilized penicillin G acylase, at this time the mass ratio of immobilized enzyme to 7-ADCA is 1:50, the temperature of the water bath is controlled at 30℃, the stirring speed is controlled to 150r / min, the reaction is 10 hours, and the magnetic force acts Isolate the immobilized enzyme under. Adjust the pH value of the upper layer solution of the separated reaction system to 5.0, and obtain cefadroxil crystals by crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com