Anti-grout-leaking sleeve joint for tension-compression composite anchor rod and anchor rod

A casing joint and composite technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of grouting, engineering safety hazards, etc., and achieve the effects of good sealing performance, engineering safety, and fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] First refer to Figure 1 to Figure 9 , a T-shaped connection sleeve 10 for a tension-compression compound anchor rod, comprising a T-shaped sleeve body and a rib hole 103 formed in the sleeve body, and the rib hole 103 extends axially from the sleeve body One end of the sleeve passes through to the other end, the sleeve body has a first cylinder section 101 and a first cylinder section 102 integrally formed, the outer diameter of the first cylinder section 101 is smaller than the outer diameter of the second cylinder section 102, and the connecting rib The hole 103 is a threaded hole matched with the anchor rod body 13 .

[0073] As a preferred mode of the present invention, the diameter of the connecting rib hole 103 is 10-30mm. As a preferred mode of the present invention, the outer diameter of the first barrel section 101 is 16-40 mm, and the outer diameter of the second barrel section 102 is 10-20 mm larger than that of the first barrel section 101 . As a preferre...

Embodiment 2

[0080] refer to Figure 10 to Figure 17 , the present invention also proposes a reinforced pressure-bearing plate for tension-compression composite bolts, including a pressure-bearing plate 11, on which the pressure-bearing plate 11 is provided with a grouting pipe perforation 112 and a rib hole 111, the pressure-bearing One end of the plate 11 along the axial direction is provided with a plurality of rib grooves 23, in the embodiment, six rib grooves 23 are shown, and the rib grooves 23 are provided with internal threads 231, and also include a plurality of reinforcing ribs 20 , the number of reinforcing ribs 20 corresponds to six, and a plurality of reinforcing ribs 20 are correspondingly threaded in the connecting rib groove 23 .

[0081] As a preferred mode of the present invention, a plurality of reinforcing ribs 20 are arranged in parallel. As a preferred mode of the present invention, the thickness of the pressure bearing plate body is 20-40 mm. As a preferred mode of...

Embodiment 3

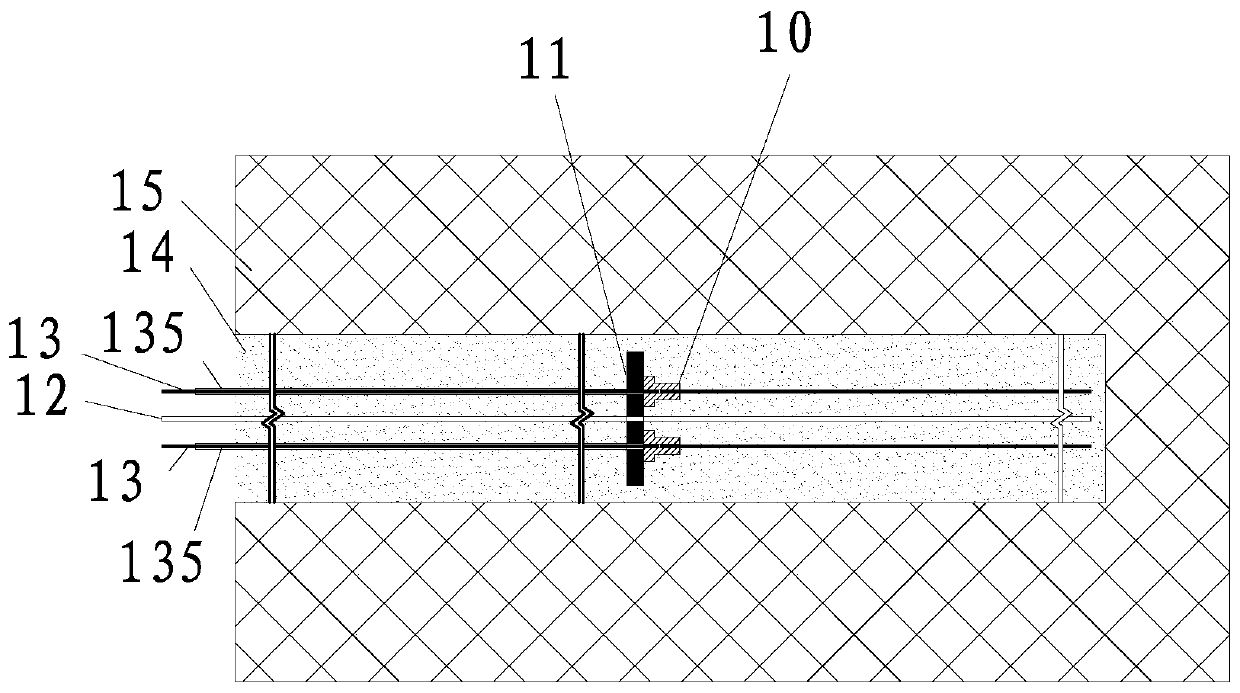

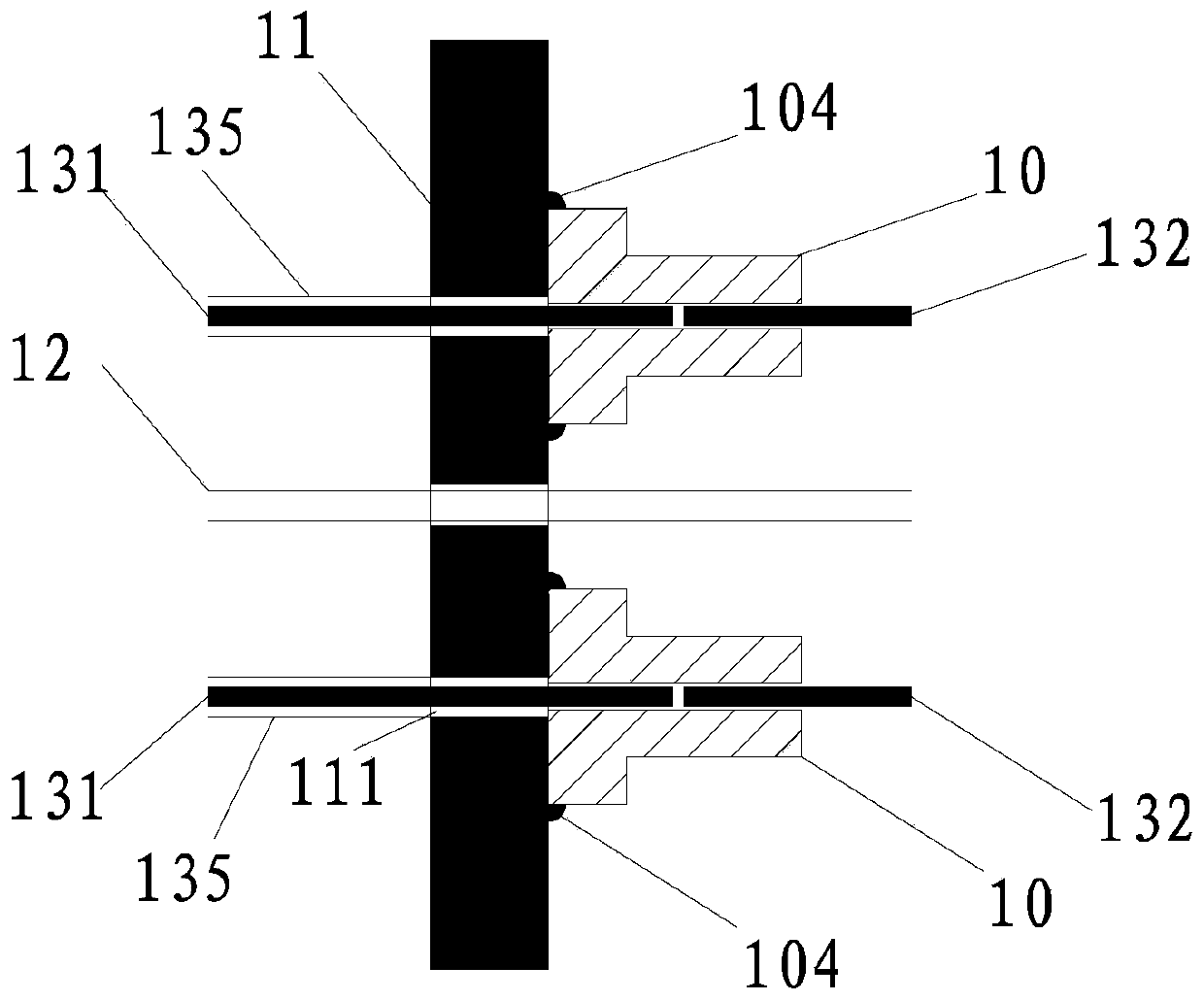

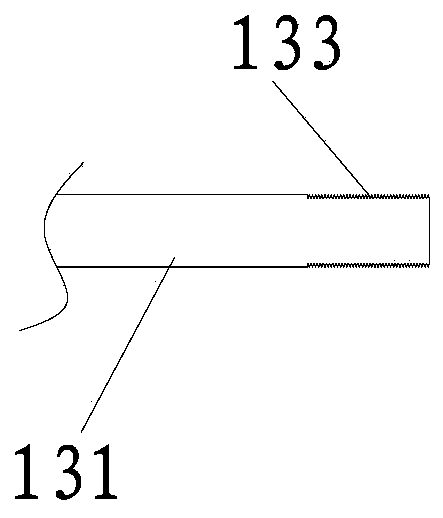

[0087] refer to Figure 18 to Figure 30 , the present invention also proposes an anti-cross-slurry casing joint for tension-compression composite anchor rods, including a screw connection pipe 30 threadedly connected with the pressure bearing plate 11, a socket pipe 31 sleeved outside the sleeve pipe 135, and a sleeve joint The screw sleeve 32 outside the sleeve pipe 31, specifically, the sleeve pipe 31 is sleeved outside the sleeve pipe 135 by hot-melt bonding, and the two axial ends of the sleeve pipe 30 are respectively set as a first end 301 and a second end 302 , the first end 301 is screwed in the screw groove 33 of the pressure bearing plate 11, the second end 302 is screwed with a screw sleeve 32, and the end of the screw sleeve 32 forms a limiting protrusion extending toward the center of the screw sleeve 32. Edge 321, threaded thread 322 is provided in screw sleeve 32, socket pipe 31 is penetrated in screw sleeve 32 and sleeve pipe 31 forms support flange 311 in scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com