Secondary Vibration System and Control Method of Pile Driver

A vibration system and pile driver technology, applied in computer control, program control, general control system, etc., can solve problems such as piles, messy hydraulic pipelines, insufficient excitation force of pile drivers, etc., to reduce fuel consumption and increase piling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

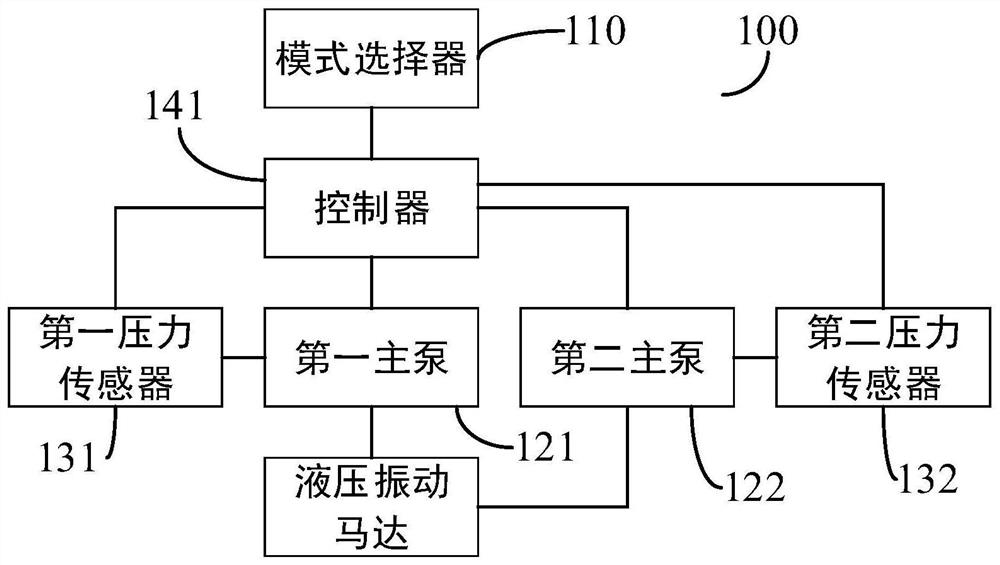

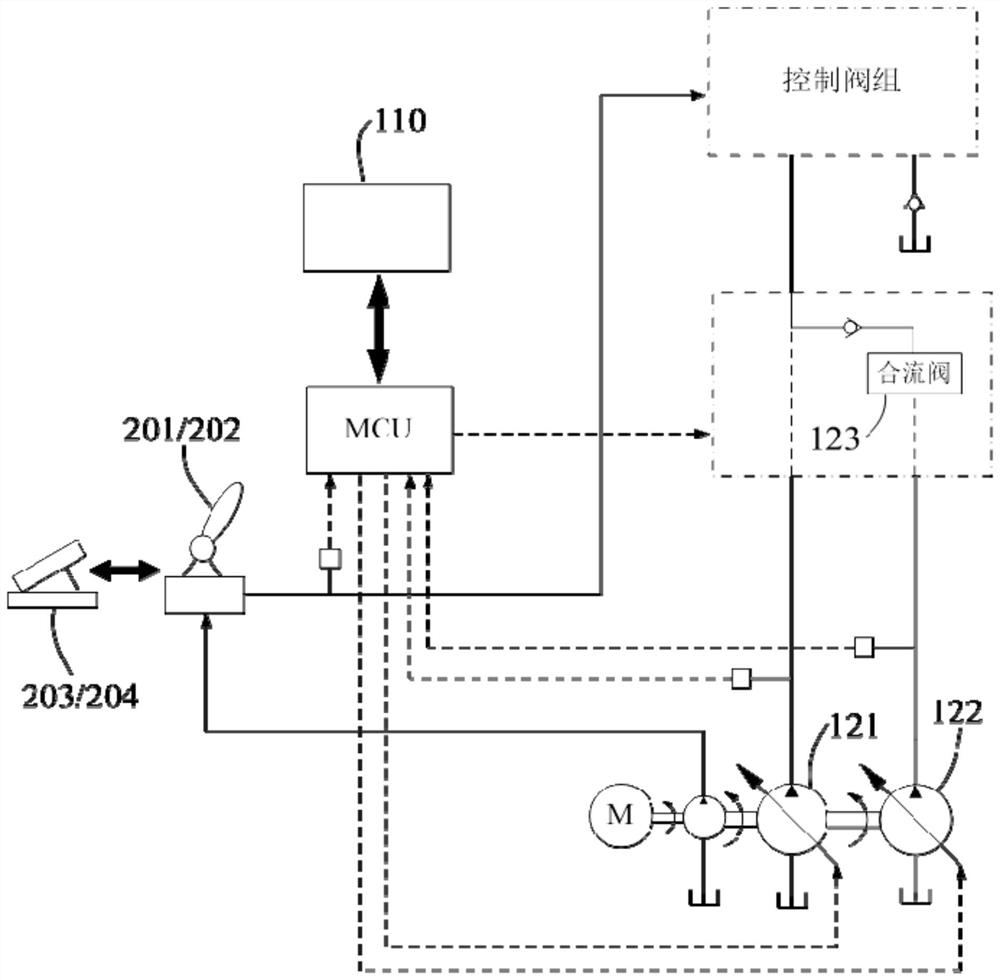

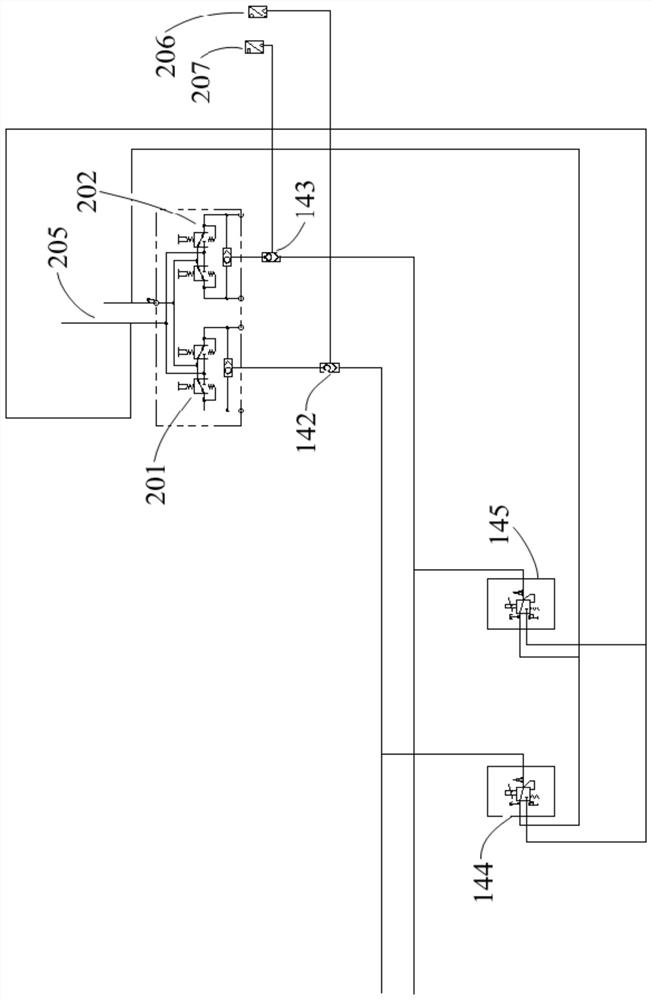

[0042] Please refer to Figure 1~3 , the present embodiment discloses a secondary vibration system 100 of a pile driver. The secondary vibration system 100 of a pile driver includes a mode selector 110, an oil supply module, a first pressure sensor 131 and a control module, reducing the complexity of hydraulic pipeline layout To a certain extent, the excitation force of the pile driver is enhanced by the secondary vibration, the piling speed is increased and the fuel consumption is reduced.

[0043] The mode selector 110 is used to acquire the selection result of the vibration mode by the user. Specifically, the mode selector 110 is an input terminal for the user to input a selection instruction, so as to realize manual switching between the primary vibration mode and the secondary vibration mode.

[0044] There are many ways to implement the input terminal. Exemplarily, the mode selector 110 is a mechanical button, a mechanical gear switch or a touch screen. For example, th...

Embodiment 2

[0063] This embodiment also discloses a secondary vibration control method of a pile driver, which is applied to the secondary vibration system 100 of a pile driver disclosed in Embodiment 1, including the following steps:

[0064] Step A: Obtain the selection result of the vibration mode by the user, and the selection result is primary vibration or secondary vibration;

[0065] Step B: obtaining the working pressure of the first main pump 121;

[0066] Step C: According to the selection result of the user and / or the working pressure of the first main pump 121 , switch control between the primary vibration mode and the secondary vibration mode is realized.

[0067] Exemplarily, the method for controlling the secondary vibration of the pile driver further includes the following steps:

[0068] Step C1: Obtain the current vibration mode of the hydraulic vibration motor;

[0069] Step C2: If the hydraulic vibration motor is in the primary vibration mode and the working pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com