Novel mechanical arm of radial lifting mechanism of loading machine

A lifting mechanism and loader technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of complicated process, material spillage, and inability to ensure the leveling of the bucket, so as to avoid material spillage and solve the problem of overturning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

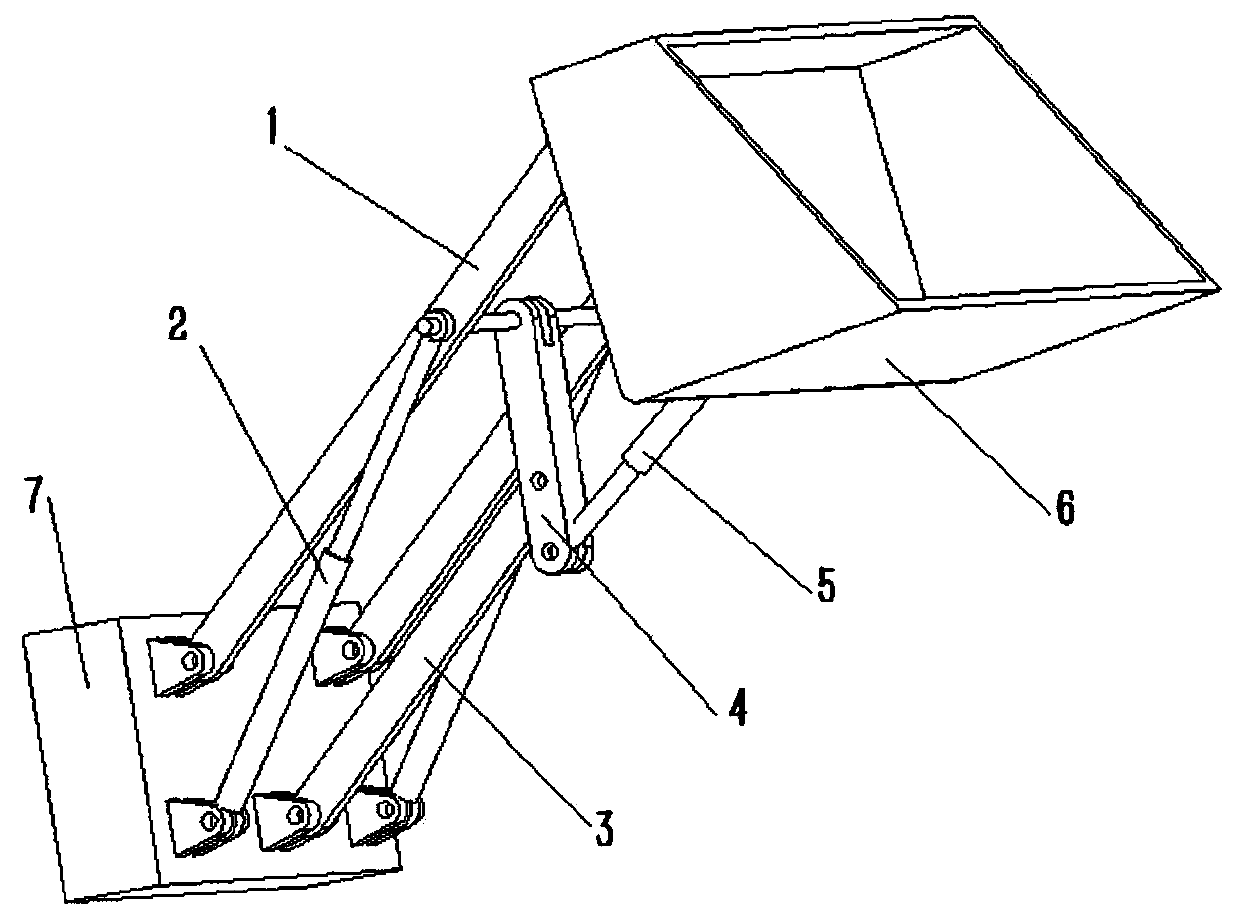

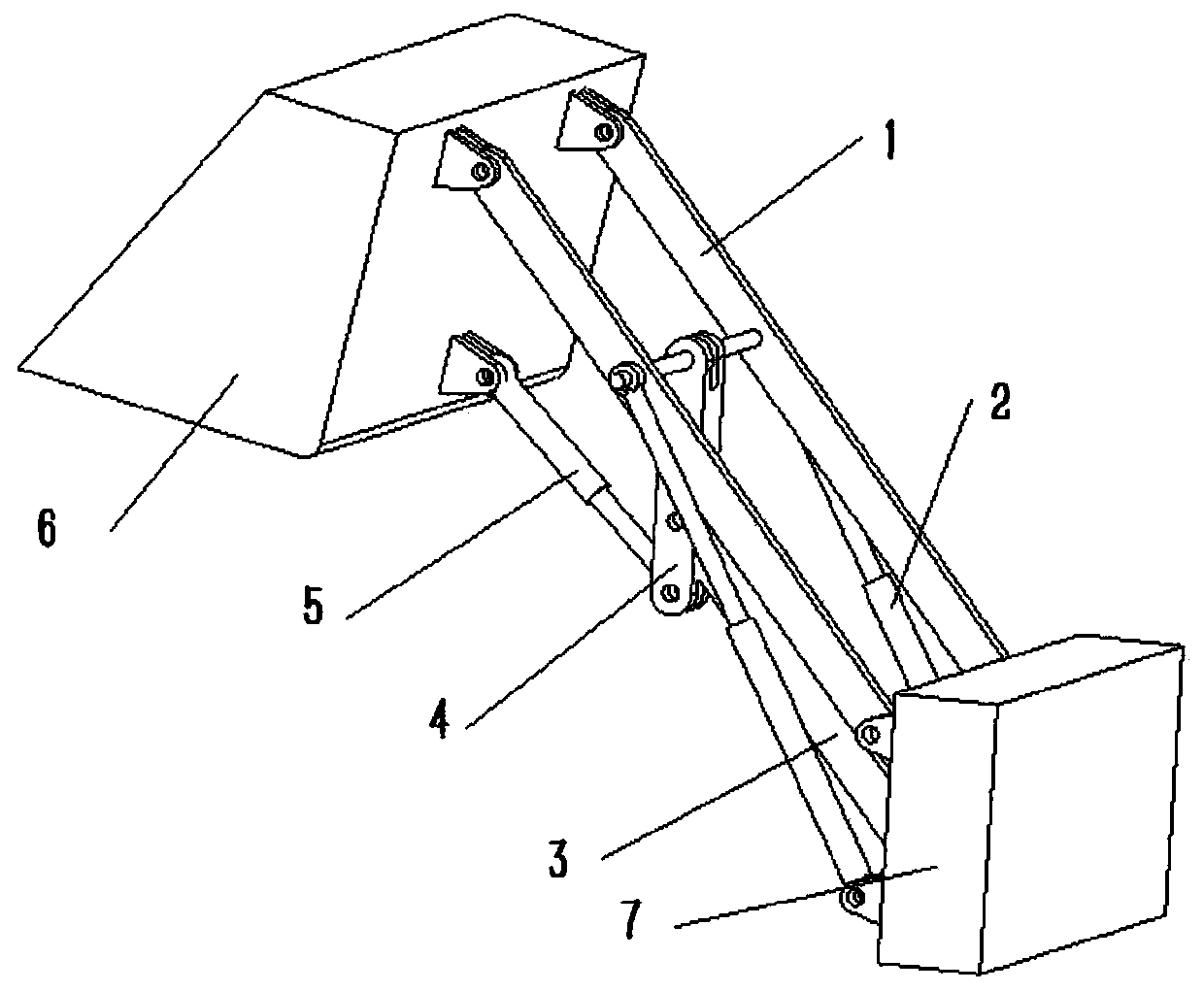

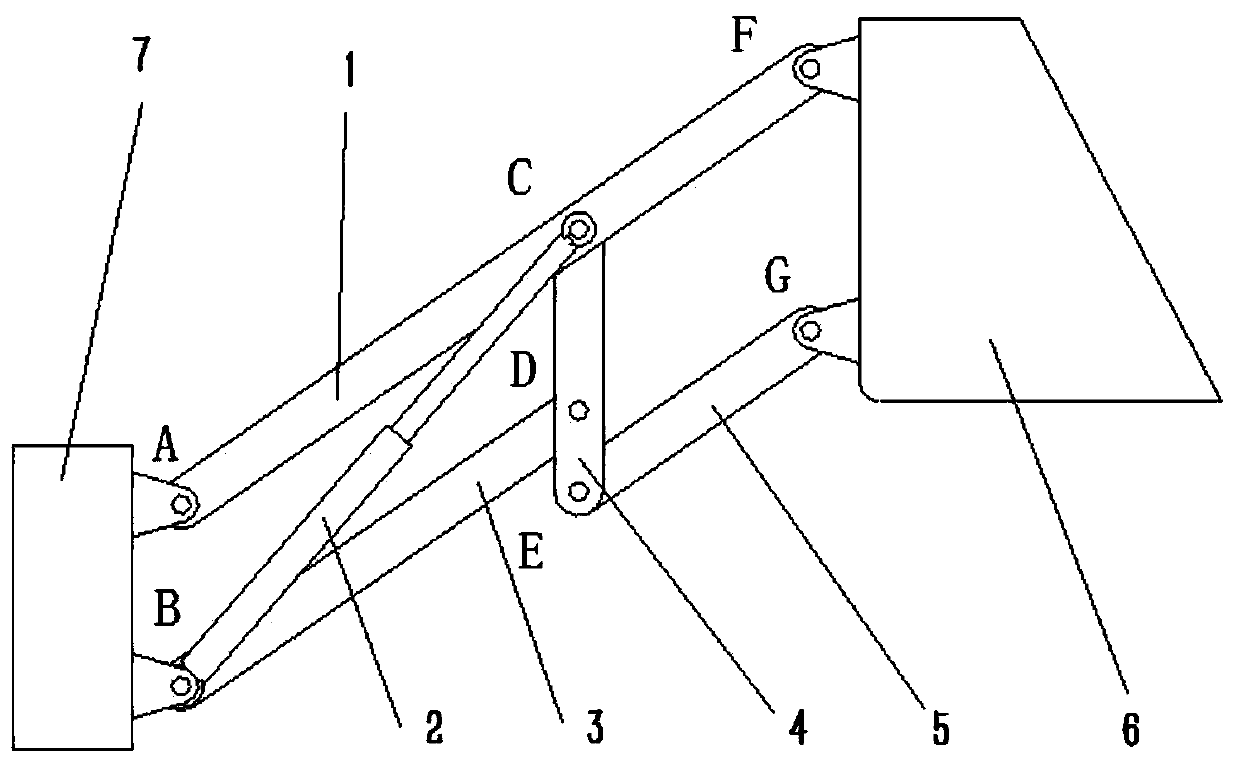

[0020] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , The present invention is a new type of loader radial lifting mechanism mechanical arm. The middle section of the big boom (1) has a cross beam for connecting the transition connecting rod (4); the new type of loader radial lifting mechanism mechanical arm is large The hinge pin at the rear end of the boom (1) is hinged to the upper part of the frame (7), and the front end is hinged to the upper part of the bucket (6). One end of the big boom hydraulic cylinder (2) is hinged to the lower part of the frame (7), and the other end is hinged to the frame (7). The middle section of the boom (1) is articulated, and the big boom hydraulic cylinder (2) provides lifting power to realize the lifting action of the bucket (6).

[0021] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , The new type loader radial lifting mechanism mechanical arm, the transition link (4) has three hinge points...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com