Self-compacting regenerated block concrete composite shear wall and construction method thereof

A technology of stacking shear walls and concrete, applied in the direction of walls, building components, buildings, etc., can solve the problems of reducing, stacking and cracking, and the bearing capacity of stacking shear walls, achieving reliable connection, solving the difficulty of placing, integrity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

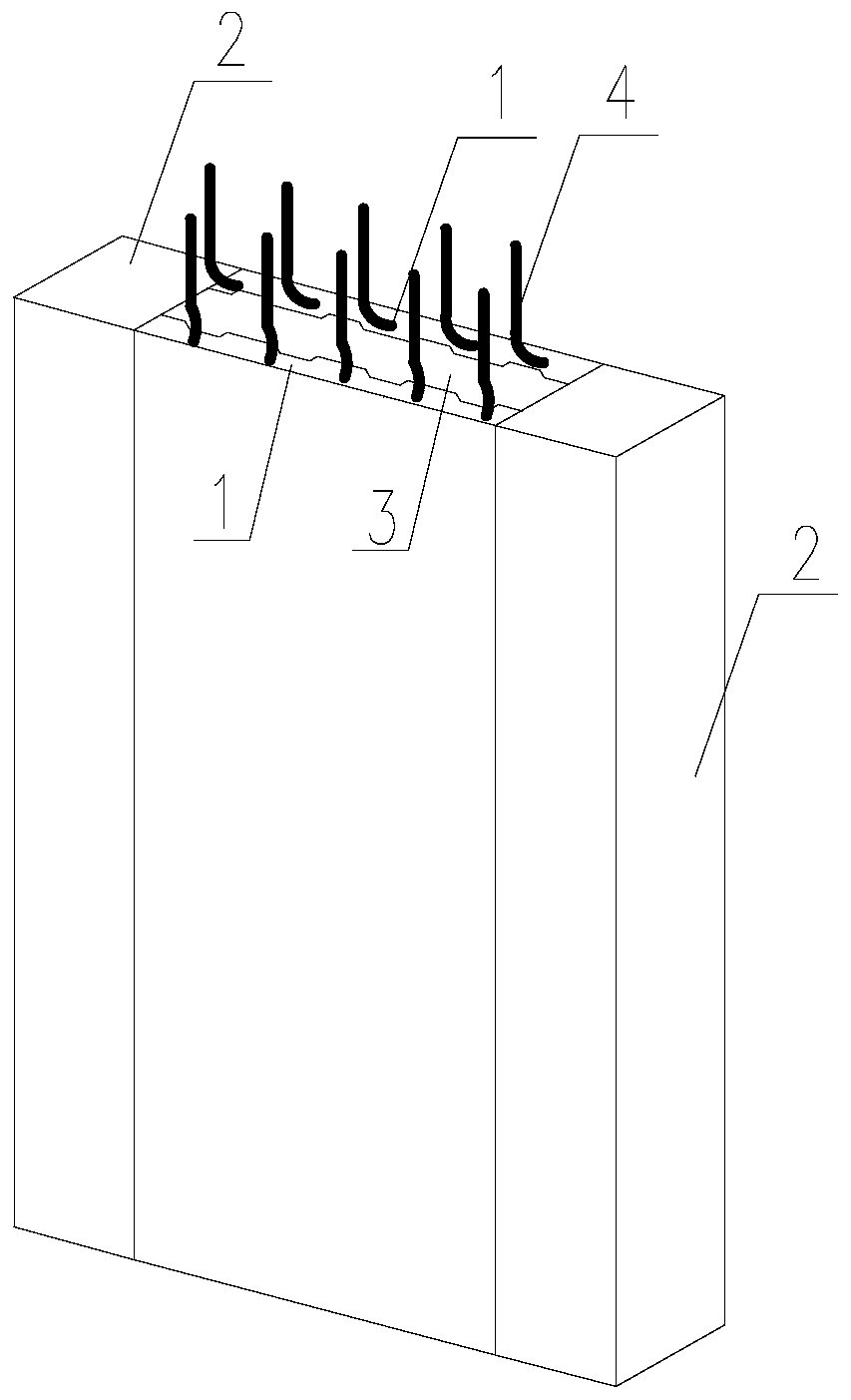

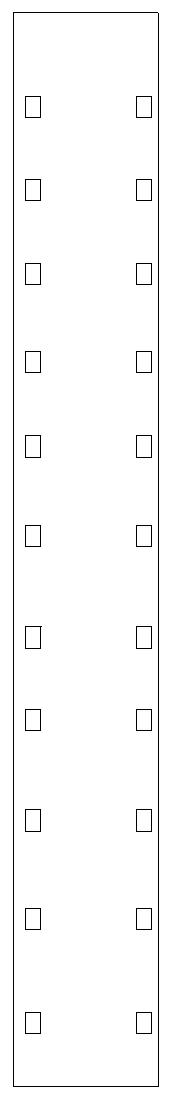

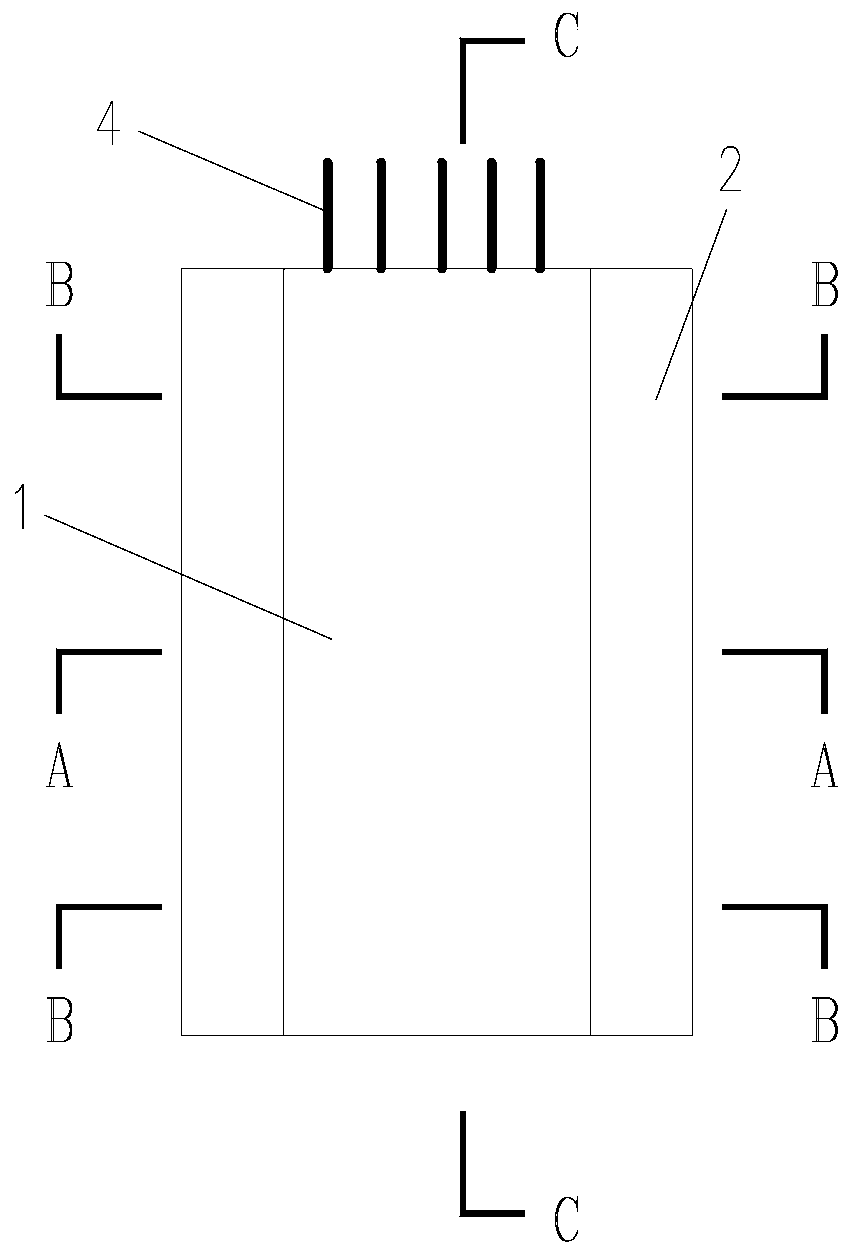

[0047] Such as Figure 1 to Figure 7 As shown, a self-compacting recycled block concrete composite shear wall includes two prefabricated concrete panels 1 arranged opposite to each other at a certain distance and two rectangular steel pipes 2 located on the left and right sides of the two precast concrete panels, wherein:

[0048] The precast concrete panel 1 and the rectangular steel pipe 2 are enclosed, and a cavity 3 is formed in the middle, and the inner sides opposite to each other of the two precast concrete panels 1 are provided with serrated surfaces;

[0049]The prefabricated concrete panel 1 is provided with a number of horizontal steel bars 5 and vertical steel bars 4, and the two ends of the horizontal steel bars 5 are respectively inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com