Heading machineinternal spraying oil-water differential pressure type active sealing device and method

An oil-water differential pressure type, active sealing technology, applied in the direction of engine sealing, earthwork drilling, slitting machinery, etc., can solve problems such as short life, and achieve the effect of prolonging life, good safety, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

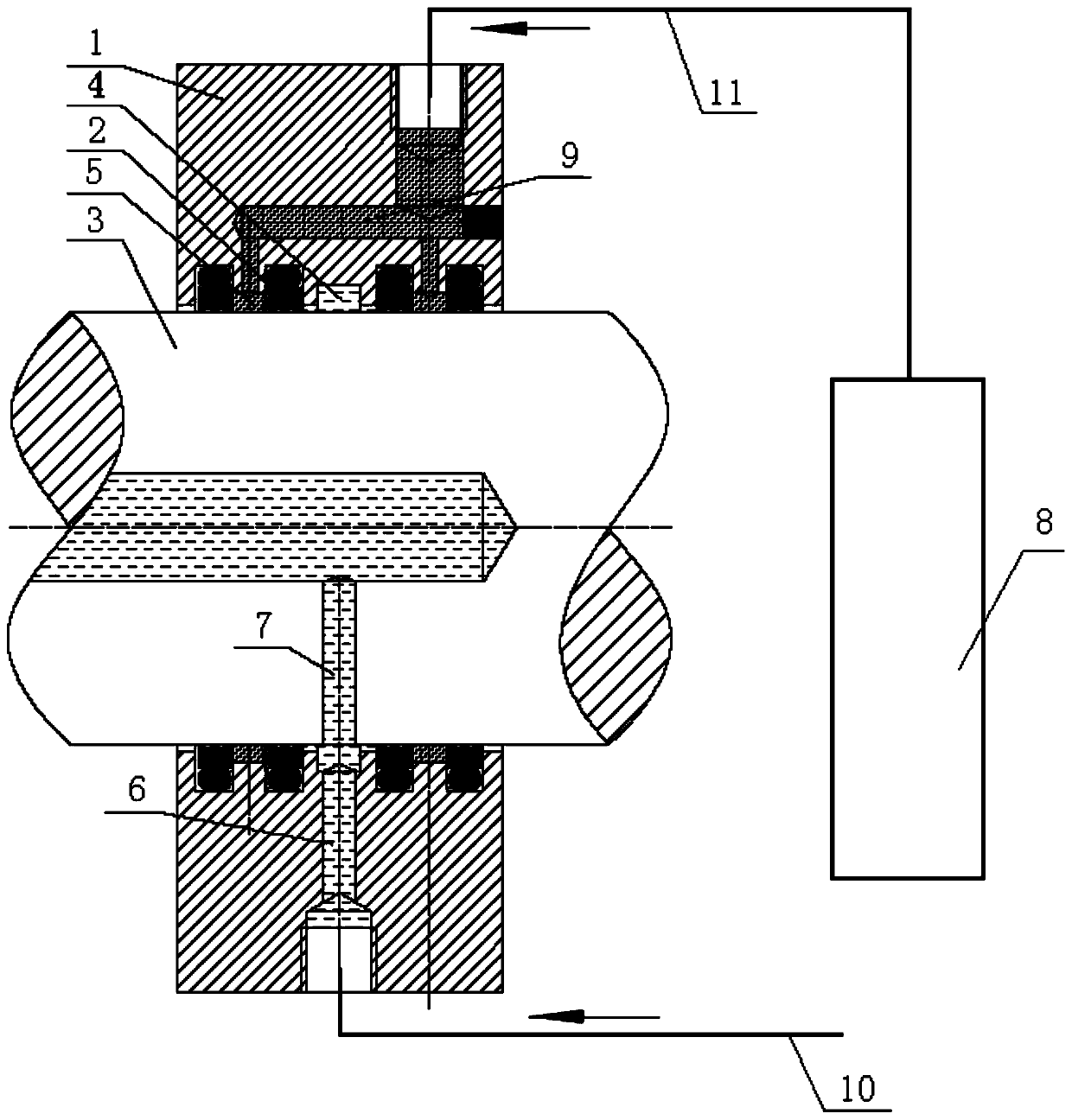

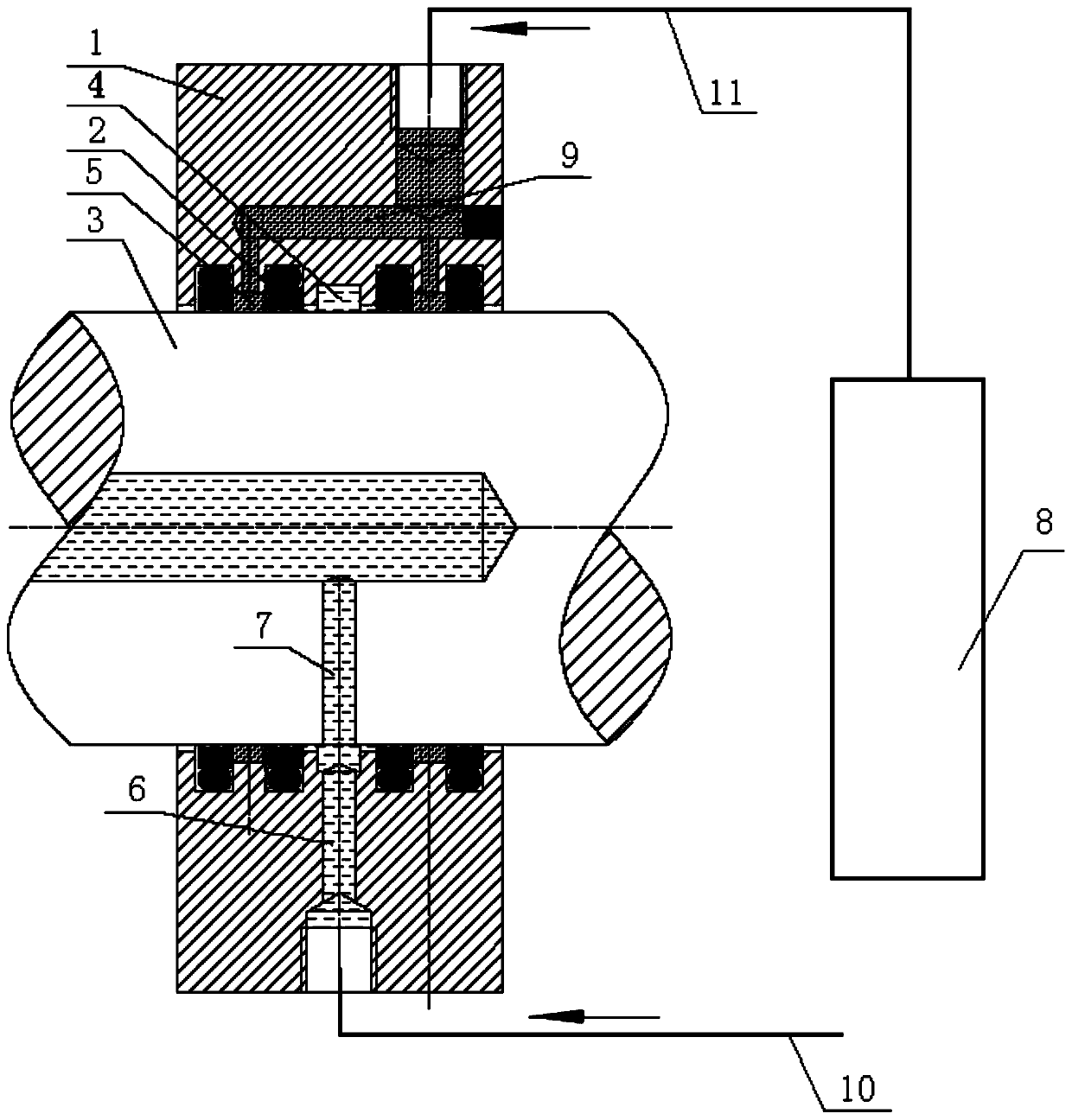

Method used

Image

Examples

Embodiment

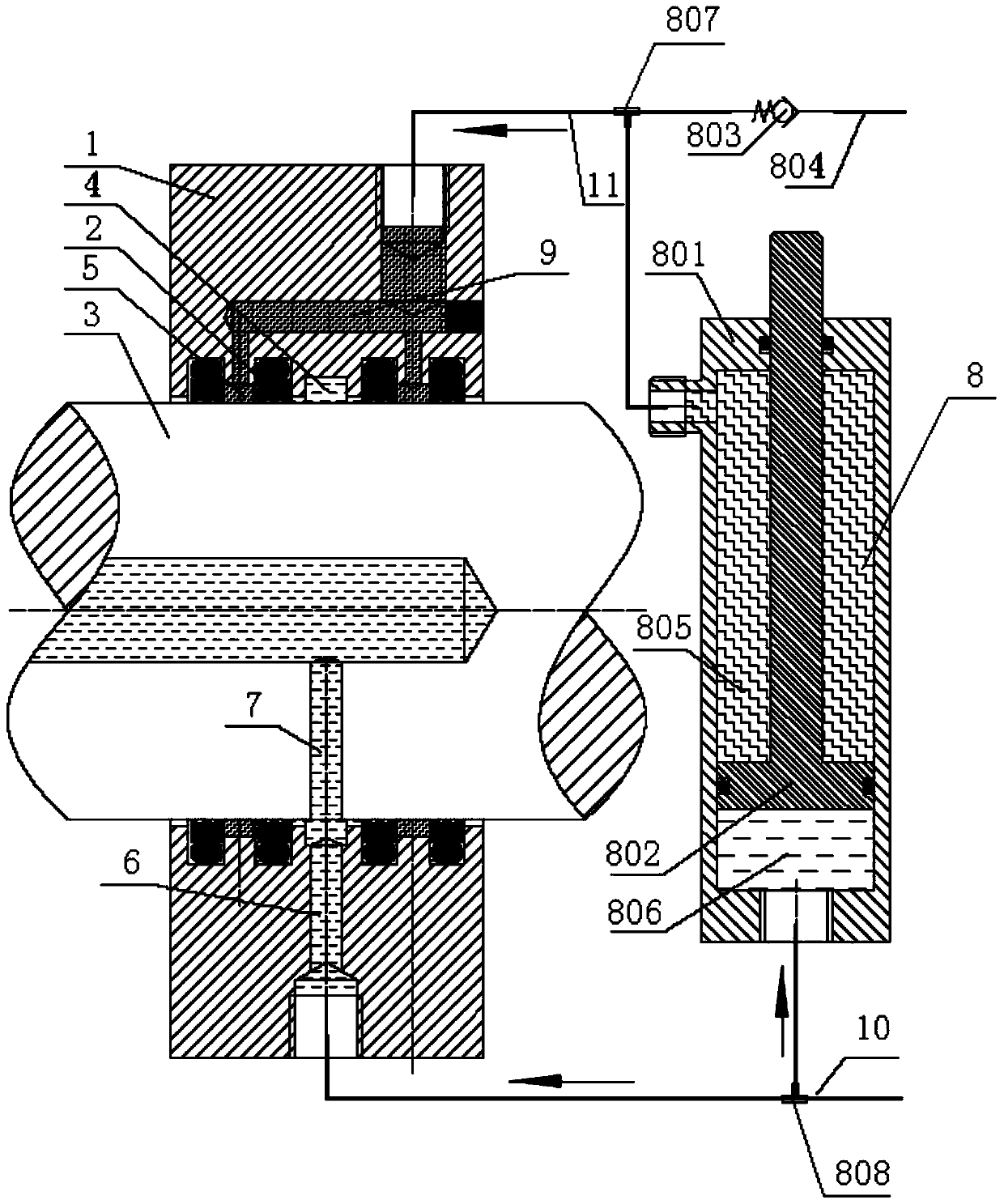

[0043] The lubricating oil supply device 8 includes a hydraulic cylinder 801, a piston with a rod 802, a check valve 803 and an oil supply pipe 804. The inside of the hydraulic cylinder 801 is provided with a piston with a rod 802, and the piston with a rod 802 connects the inside of the hydraulic cylinder 801. Part of it is the hydraulic cylinder oil chamber 805 and the hydraulic cylinder water chamber 806; the inlet end of the oil supply pipe 11 is fixedly connected with the outlet of the tee I 807; the first inlet of the tee I 807 is connected to the hydraulic cylinder oil chamber 805 through a pipeline , the second inlet of the three-way I 807 is connected to the outlet of the one-way valve 803 through a pipeline; the inlet of the one-way valve 803 is connected to the oil-charging pump through the oil-charging pipe 804;

[0044] The inlet end of the water supply pipe 10 is connected to the spray pump, and the outlet end is fixedly connected to the inlet of the three-way II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com