Electric control silicon oil fan clutch

A clutch and silicone oil technology, applied in the direction of machine/engine, coolant flow control, engine components, etc., can solve the problems of low heat dissipation efficiency, short service life, slow response speed, etc., to reduce the processing process, facilitate later maintenance, The effect of speeding up the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

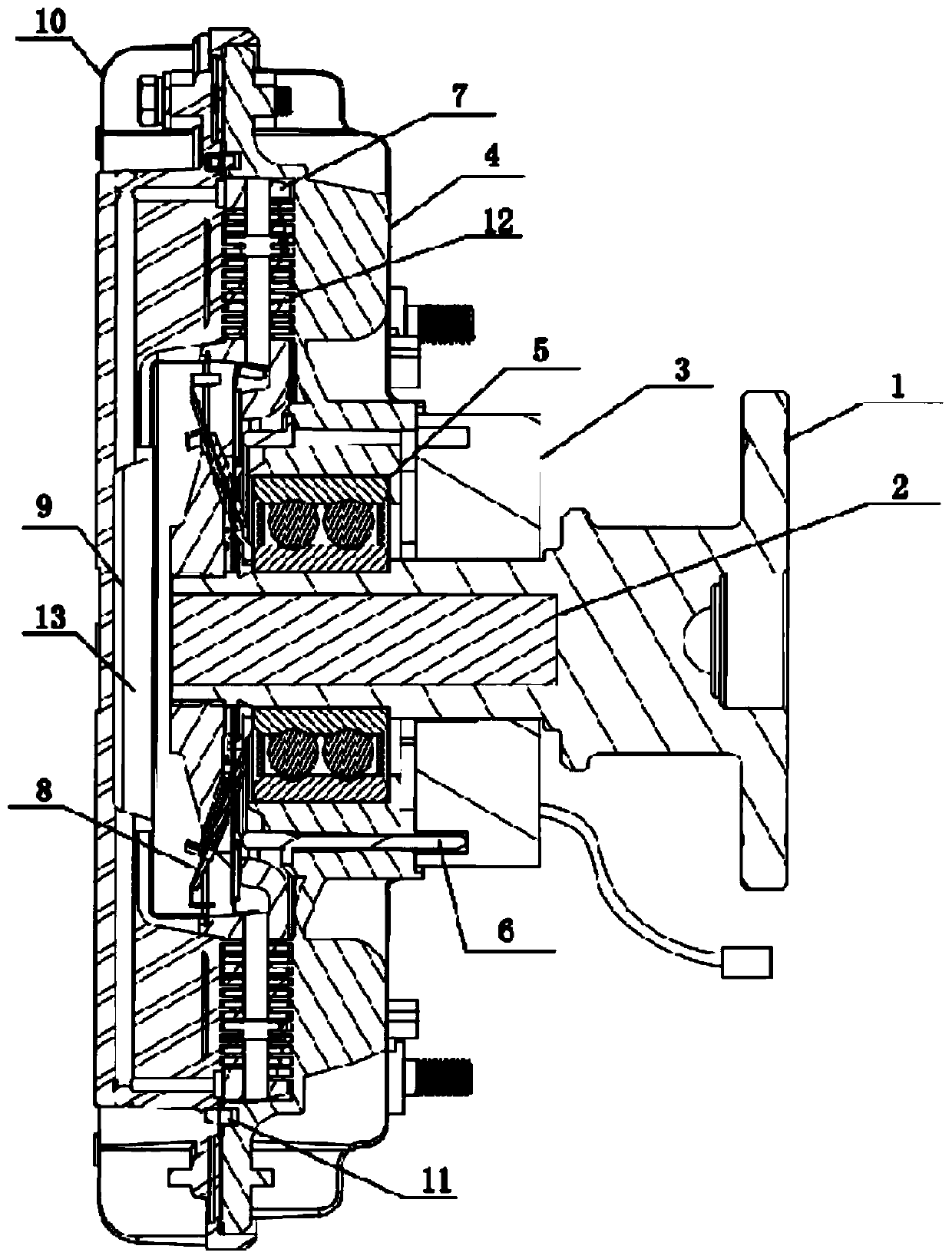

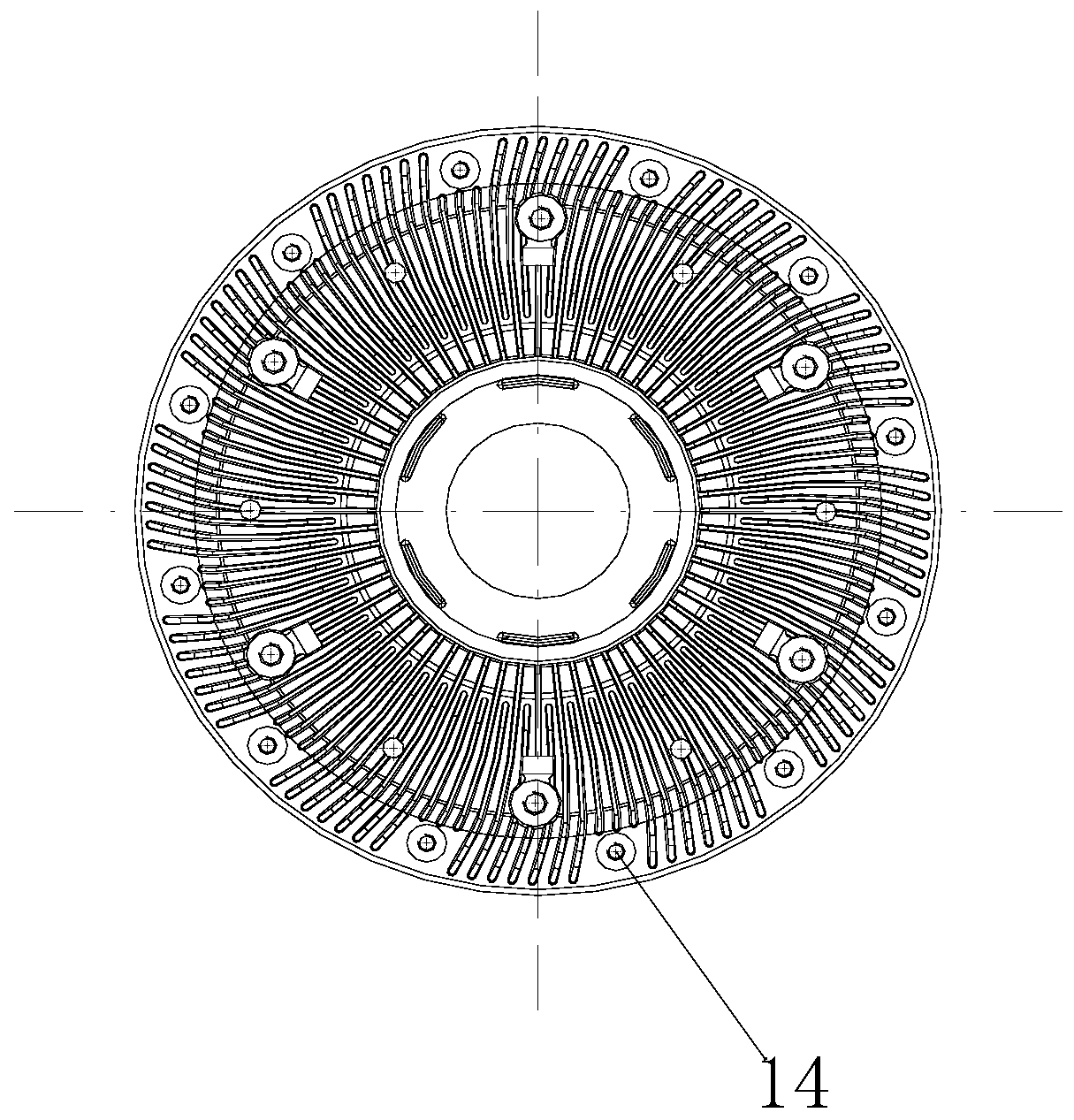

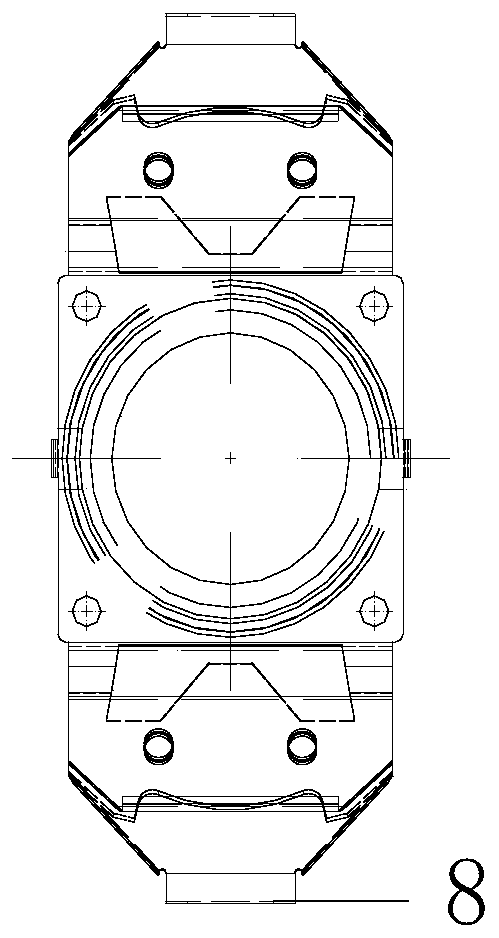

[0013] Such as figure 1 As shown, an electronically controlled silicon oil fan clutch includes: driving shaft 1, magnetic guide column 2, yoke coil 3, housing 4, bearing 5, counting ring 6, driving plate 7, valve plate 8, driven Plate 9, front cover 10, sealing ring 11, working chamber 12 and oil storage chamber 13. Such as figure 2 As shown, the front cover 10 and the housing 4 are assembled by bolts 14, which solves the maintenance in the middle and late stages of use without affecting the sealing, and also prolongs the service life of the electronically controlled silicon oil fan clutch. The front cover 10 and the housing 4 are sealed by the sealing ring 11 to form the oil storage chamber 13, the working chamber 12 and the flow channel; Silicone oil isolation, the active plate 7 is assembled on the drive shaft 1, coaxial with the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com