Differential type laminar flow rate measuring method and device

A flow measurement device and flow measurement technology, which are applied in the direction of measuring fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve problems such as complex data processing models and difficult correction results, and reduce nonlinear components , easy correction, and simple calculation model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

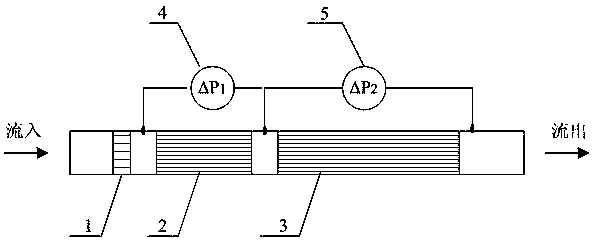

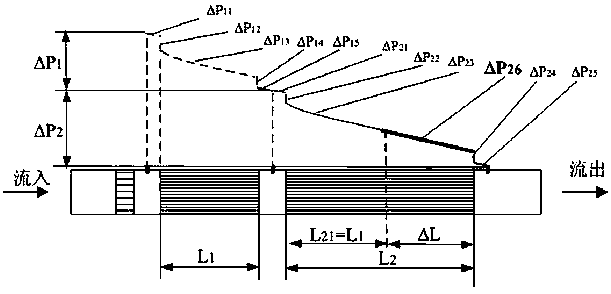

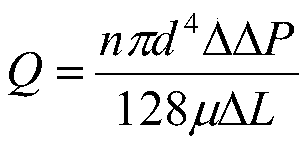

[0028] figure 1 It is a schematic diagram of a differential laminar flow measurement device. The measuring device is provided with a measuring pipeline, which is mainly composed of a flow regulator 1 , a first laminar flow element 2 , a second laminar flow element 3 , a first differential pressure sensor 4 , and a second differential pressure sensor 5 . Wherein, the first laminar flow element 2 and the second laminar flow element 3 are connected in series in the measuring pipeline, and the first laminar flow element 2 and the second laminar flow element 3 contain capillaries with the same diameter and number inside, and the capillary lengths are different, respectively L 1 and L 2 ,Such as figure 2 As shown, the length of the capillary in the first laminar flow element and the second laminar flow element must exceed the length of the flow inlet section, and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com