Optical module packaging structure and optical module

A packaging structure and optical module technology, applied in the coupling of optical waveguides, etc., can solve the problems of increasing thermal resistance, narrow product operating temperature range, and difficulty in dissipating module heat, reducing thermal resistance, enhancing thermal conduction efficiency, and solving heat dissipation problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

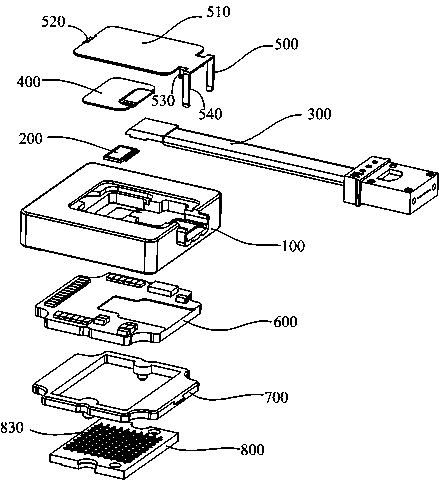

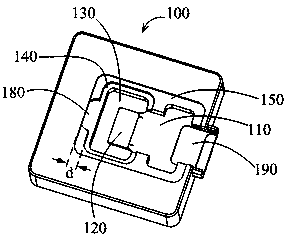

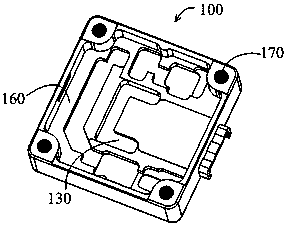

[0033] This embodiment is aimed at chips (such as optical transceiver chips, driver chips, etc.) that easily generate heat during the working process of optical modules (such as optical transmitting modules, optical receiving modules, or optical transceiver modules, etc.). Fast, and when the temperature reaches the limit value, the performance of the chip will deteriorate or stop running directly, affecting the normal operation of the optical module). ), a high-efficiency heat dissipation optical module packaging structure is proposed, such as figure 1 As shown, it includes the metal shell 100, the top cover 500, the bottom plate 700 and other main components, which are used to package the chip 200 in the optical module, the circuit board 600, the optical connector 310 at the front end of the optical component 300, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com