Small lens and under-screen optical assembly

A technology of optical components and lenses, applied in optical components, optics, installation, etc., can solve problems such as difficult screen-to-body ratio and large size, and achieve the effect of improving screen-to-body ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

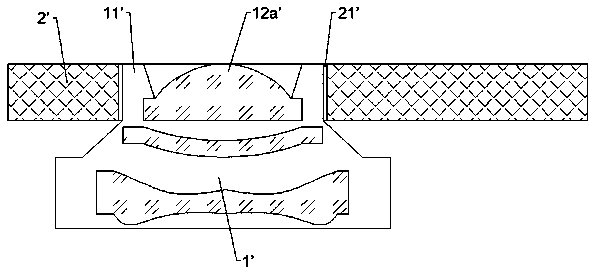

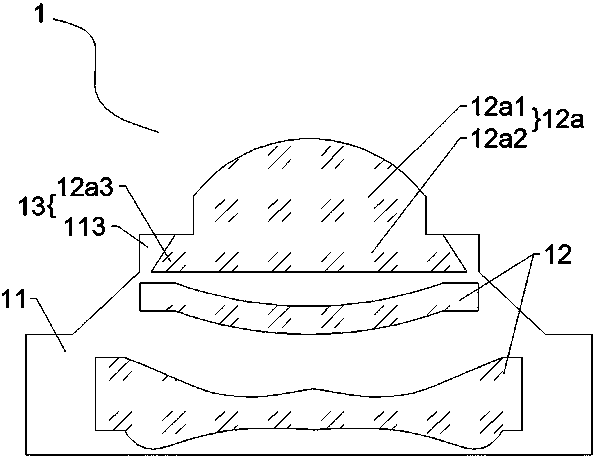

[0022] like figure 2 As shown, a small lens 1 includes a lens barrel 11 and a plurality of optical lenses 12 arranged in the lens barrel 11 along the optical axis direction, and the plurality of optical lenses 12 include an entrance lens located in the lens barrel 11. The incident lens 12a at the light end; the incident lens 12a includes a fixed part 12a2 and a protruding part 12a1 connected along the optical axis direction, the fixed part 12a2 is installed in the lens barrel 11, and the protruding part 12a1 is higher than the light incident end surface of the lens barrel 11 , and the diameter of the protrusion 12a1 is smaller than the outer diameter of the light incident end of the lens barrel 11 .

[0023] The small lens 1 protrudes the light incident lens 12a located at the light incident end, so that it is higher than the light incident end face of the lens barrel 11 and has a diameter smaller than the light incident end outer diameter of the lens barrel 11, so that The ...

Embodiment 2

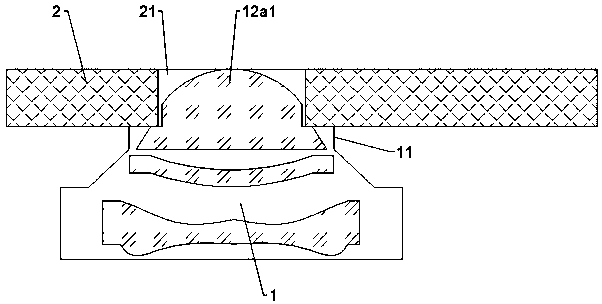

[0029] like image 3 As shown, an under-screen optical assembly includes a display screen 2 with an avoidance groove / hole 21 and the small lens 1 described in Embodiment 1, the small lens 1 is arranged on the back of the display screen 2 and inserted into the The protruding portion 12a1 of the light lens 12a extends into the avoidance groove / hole 21 of the display screen 2, and the light-incident end face of the lens barrel 11 is against the periphery of the display screen 2 at the avoidance groove / hole 21. back.

[0030] Preferably, the light-incident end face of the lens barrel 11 is bonded and fixed to the peripheral back surface of the display screen 2 at the avoidance groove / hole 21 through an adhesive, and the adhesive is acrylic or epoxy. The highly transparent adhesive material such as resin can be but not limited to OCA glue.

[0031] The avoidance groove / hole 21 can be a side groove set outside the display area of the display screen 2, that is, the display screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com