AGV autonomous scheduling system and AGV autonomous scheduling method

A technology for autonomous dispatching and dispatching of equipment, applied in the direction of total factory control, electric/hybrid power, comprehensive factory control, etc., can solve problems such as production control failures, multiple programs, and high processor pressure, and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

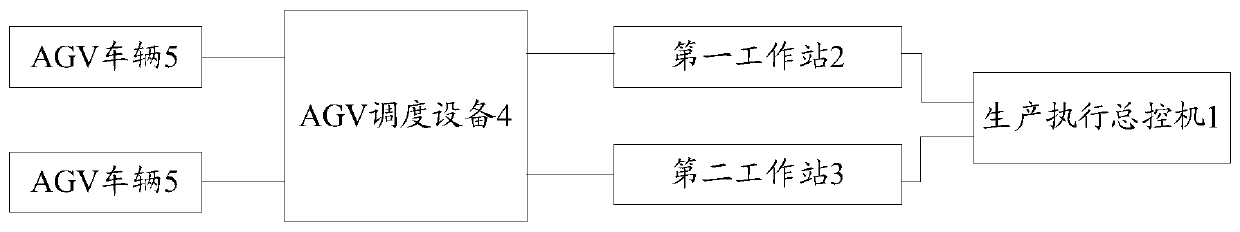

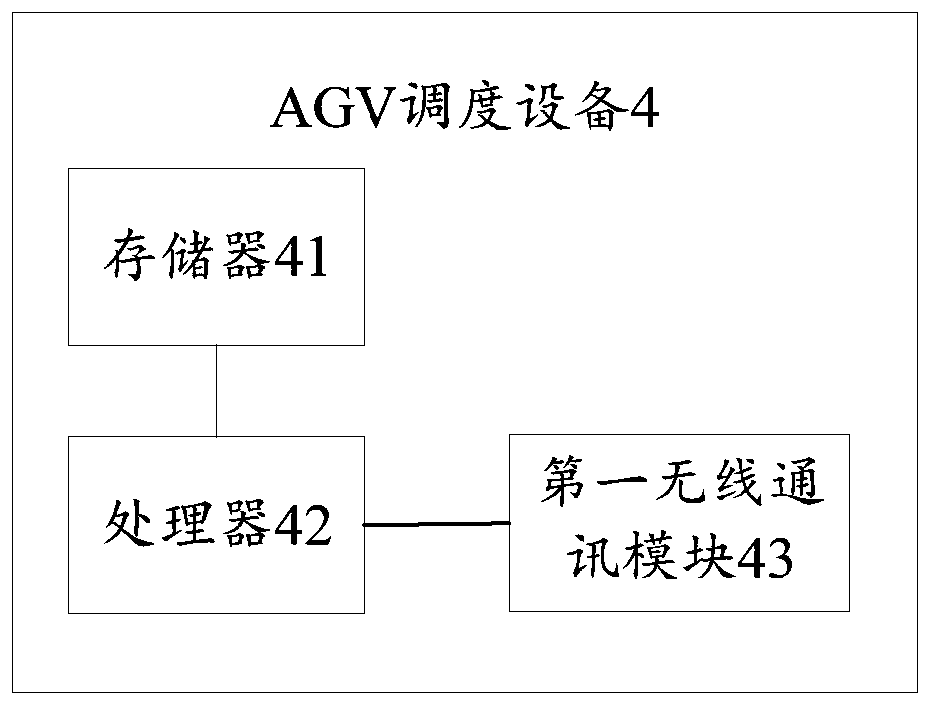

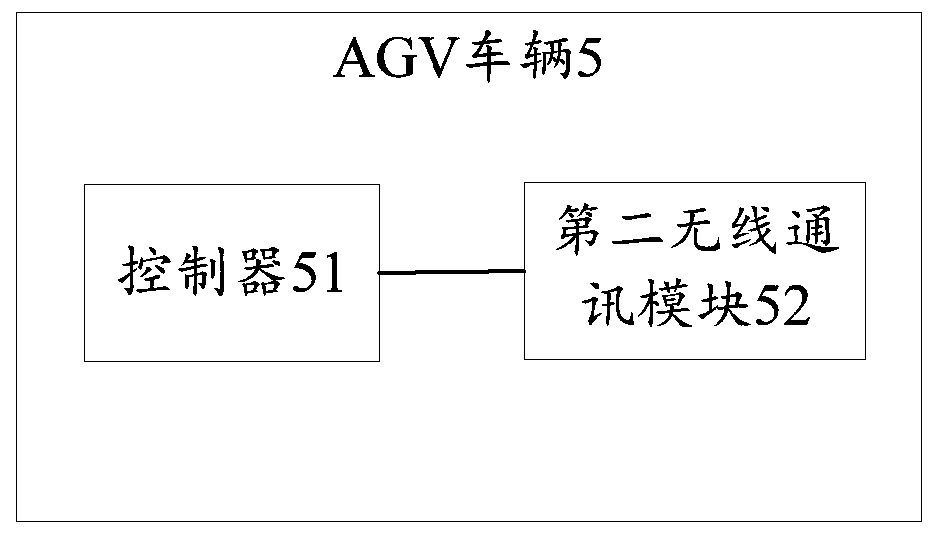

[0038] This embodiment provides an AGV autonomous scheduling system, such as figure 1 As shown, the AGV autonomous dispatching system includes a master production execution control machine 1, an AGV dispatcher 4, an AGV vehicle 5, and a workstation connected to the master production execution control machine 1, as well as a material warehouse. The material warehouse is used to store various materials used in production.

[0039] In the actual production process, multiple workstations are connected to the master production execution control machine 1 . For example, in an automobile production workshop, there may be gluing workstations, welding workstations, etc. These workstations are connected to the production execution master control machine 1, receive the production tasks sent by the production execution master control machine, and determine the production tasks according to the received production tasks. Material requirements information. exist figure 1 In the illustrat...

Embodiment 2

[0053] This embodiment provides an AGV autonomous scheduling method, which is applied to the AGV autonomous scheduling system provided in the first embodiment above, such as Figure 4 As shown, the method includes:

[0054] Step S400, the workstation receives the production task sent by the production execution master control machine, generates material demand information according to the production task, and sends the material demand information to the AGV scheduling device;

[0055] In step S402, the AGV scheduling device dispatches the AGV vehicle to transport the material from the material warehouse to the workstation that sends the material demand information according to the received material demand information.

[0056] Specifically, the AGV scheduling device analyzes the received material demand information, and obtains the location of the workstation that sends the material demand information and the material warehouse where the required materials are located. For ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com