Making method for customized shoes by utilizing multi-data collection and made customized shoes

A manufacturing method and multi-data technology, applied in processing and manufacturing, footwear, applications, etc., to achieve the effect of improving wearing comfort and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate the understanding of the present disclosure, the present disclosure enumerates the following examples. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present disclosure, and should not be regarded as specific limitations on the present disclosure.

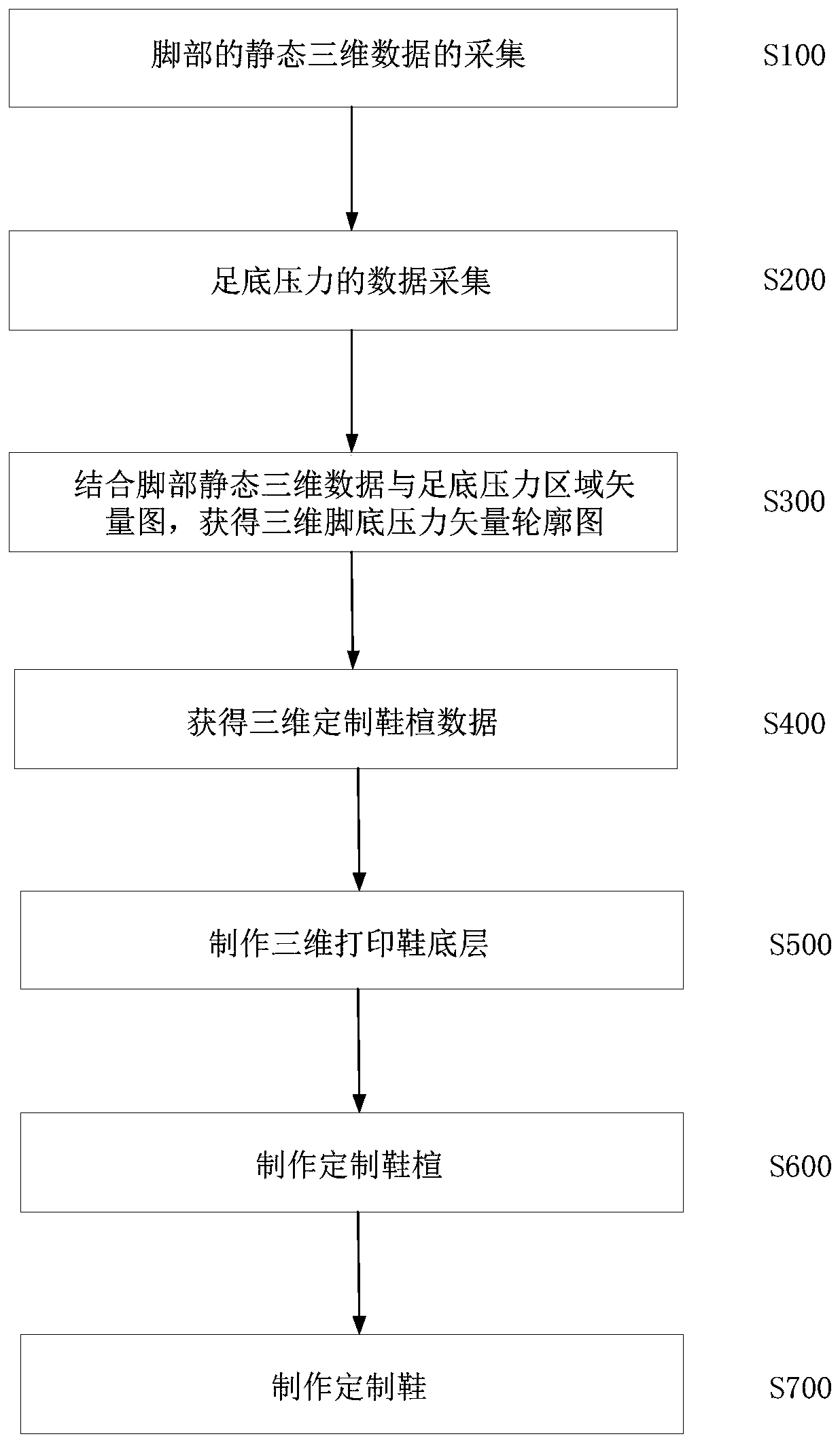

[0045] figure 1 It is a process flow diagram depicting a method for manufacturing customized shoes using multiple data collection provided by a specific embodiment of the present disclosure. Such as figure 1 As shown, in a specific embodiment, the present disclosure provides a method for manufacturing customized shoes using multiple data collection, including the following steps:

[0046] Step S100: collecting the static 3D data of the foot to obtain the static 3D data of the foot;

[0047] Step S200: Collect data on the plantar pressure to obtain a vector map of the plantar pressure area; in a specific embodiment, the vector map 2001 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com