Filtering device for pharmaceutical device

A technology for pharmaceutical equipment and filtering device, applied in the field of filtering device for pharmaceutical equipment, can solve the problems of affecting filtering effect, affecting work efficiency, increasing labor intensity of staff, etc., and achieving the effect of improving filtering efficiency, improving work efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

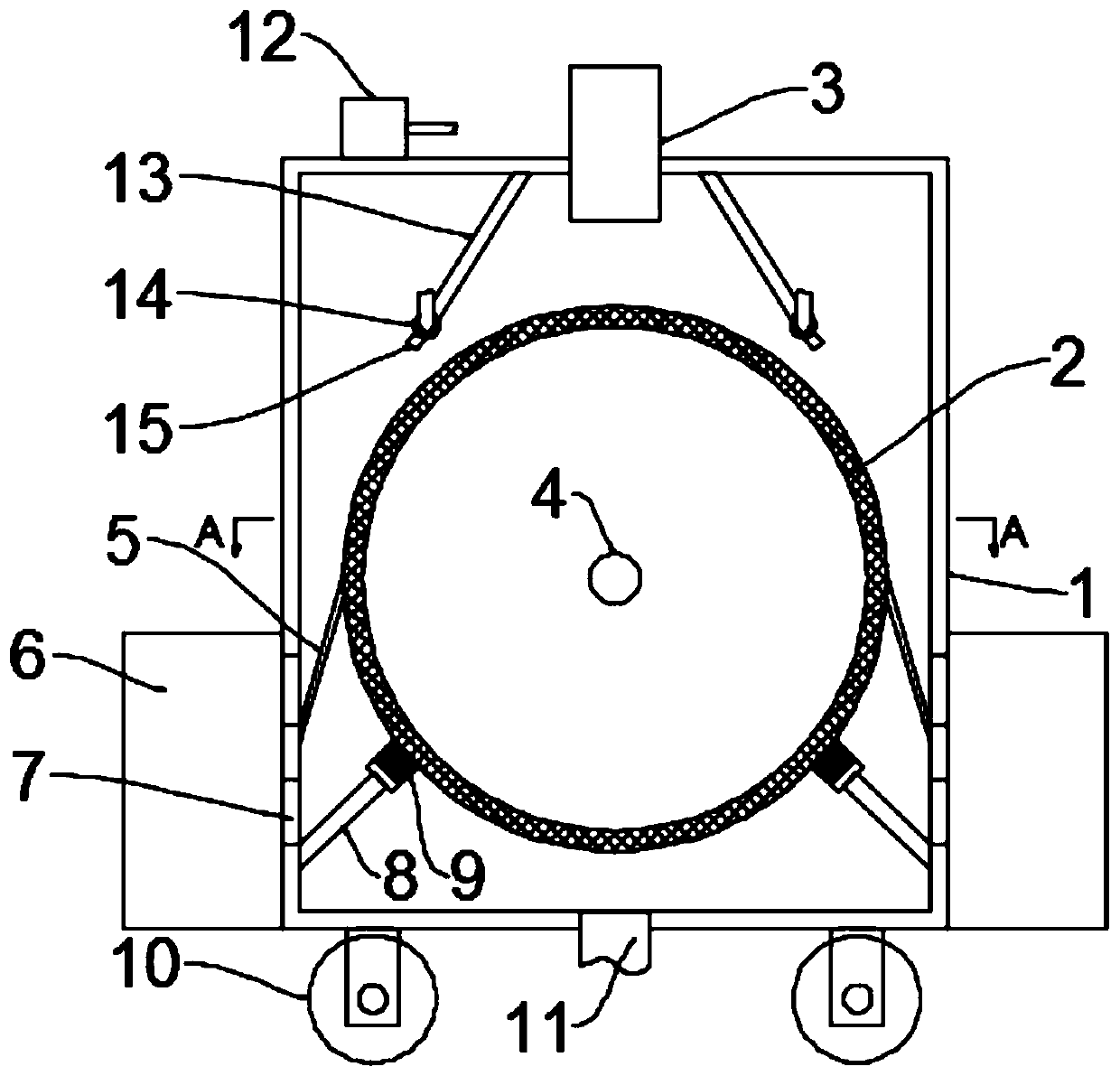

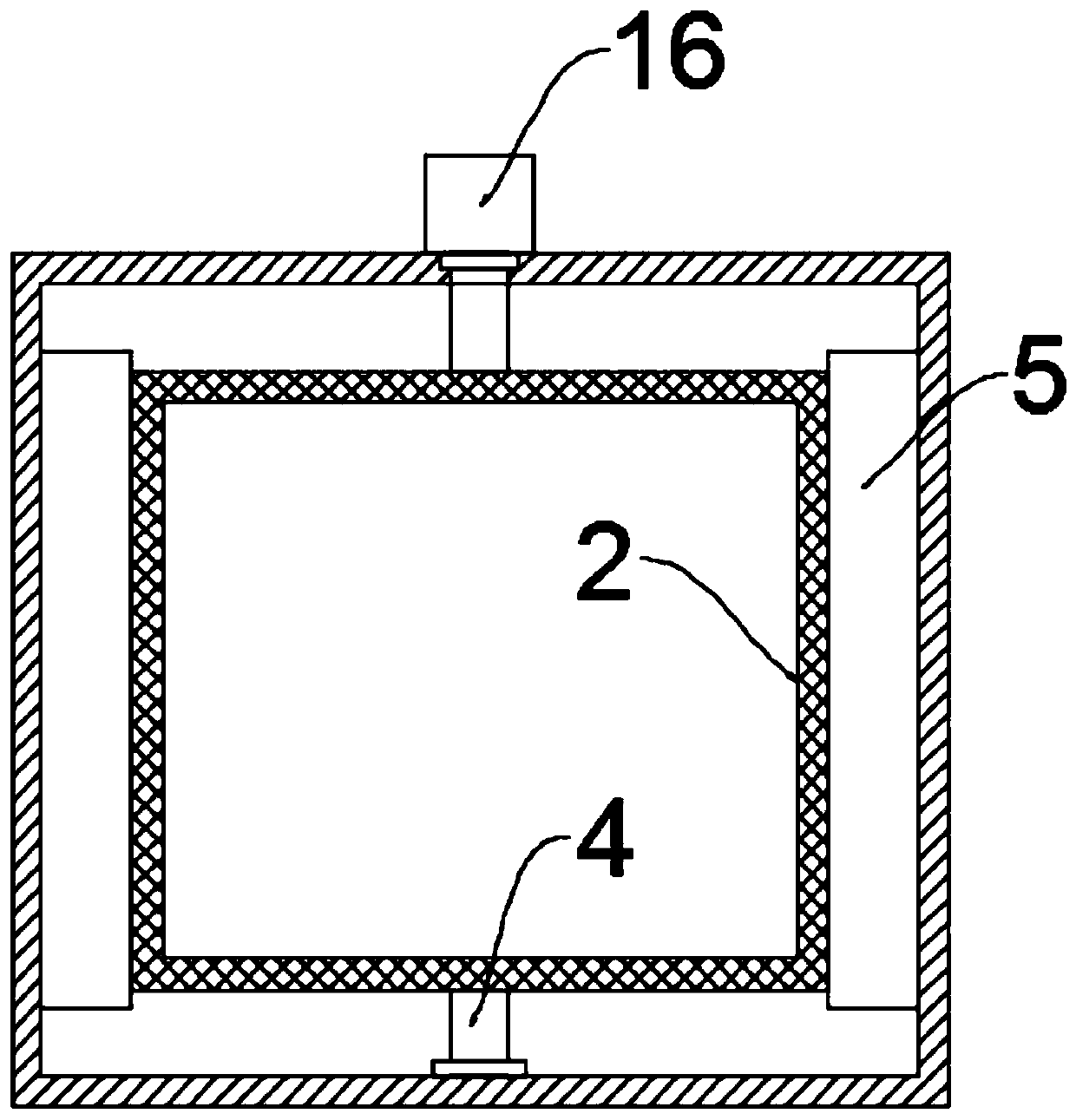

[0025] see Figure 1~2 , in the embodiment of the present invention, a filter device for pharmaceutical equipment, including a box body 1 and a filter mechanism, rollers 10 are installed on the four corners of the bottom of the box body 1, and the rollers 10 are self-locking rollers, which facilitate the installation of the device. Move, the middle of the top of the box body 1 is connected with the liquid inlet pipe 3, the bottom of the box body 1 is connected with the liquid outlet pipe 11, and a filter mechanism is provided inside the box body 1, and the filter mechanism includes a filter screen cylinder 2, a motor 16, and a scraper 5 and the brush bar 9, the two ends of the filter cylinder 2 are installed in the box body 1 through the installation shaft 4 and bearing rotation, and the end of the installation shaft 4 on one side of the filter cylinder 2 is connected to the output shaft of the motor 16 through a coupling Fixed connection, the motor 16 is installed on the side...

Embodiment 2

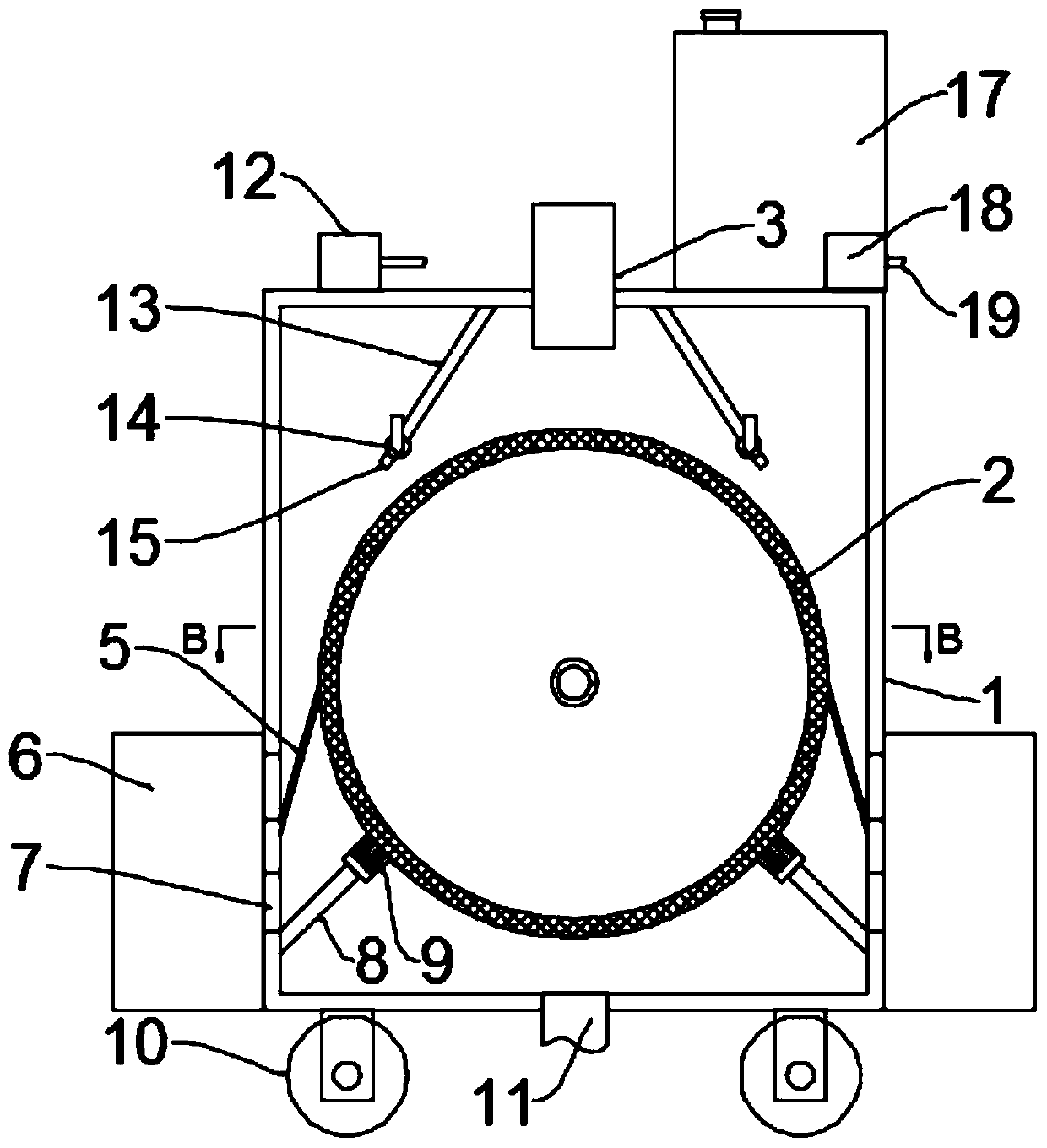

[0027] see Figure 3-4 The difference between the embodiment of the present invention and embodiment 1 is that it also includes a backwashing device, and the backwashing device includes a water tank 17, a water pump 18 and a hard water pipe 21, and the water tank 17 is installed on the tank body 1, and the water tank The top of 17 is provided with a water replenishment port, the water tank 17 is provided with a water pump 18, and the water pump 18 is connected with a water supply pipe 19. The hard water pipe 21 is arranged on the center line of the filter cylinder 2, and the hard water pipe 21 is uniformly provided with a plurality of spray holes 20. The end of the hard water pipe 21 away from the motor 16 runs through the end wall of the filter cylinder 2 and the side wall of the box body 1 and extends to the outside of the box body 1. The hard water pipe 21 is fixedly connected to the side wall of the box body 1. The water supply pipe 19 passes through the water pipe The joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com