Efficient installation method of dust cover hoop

An installation method and technology of dust cover, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of time-consuming and laborious installation method of dust cover clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

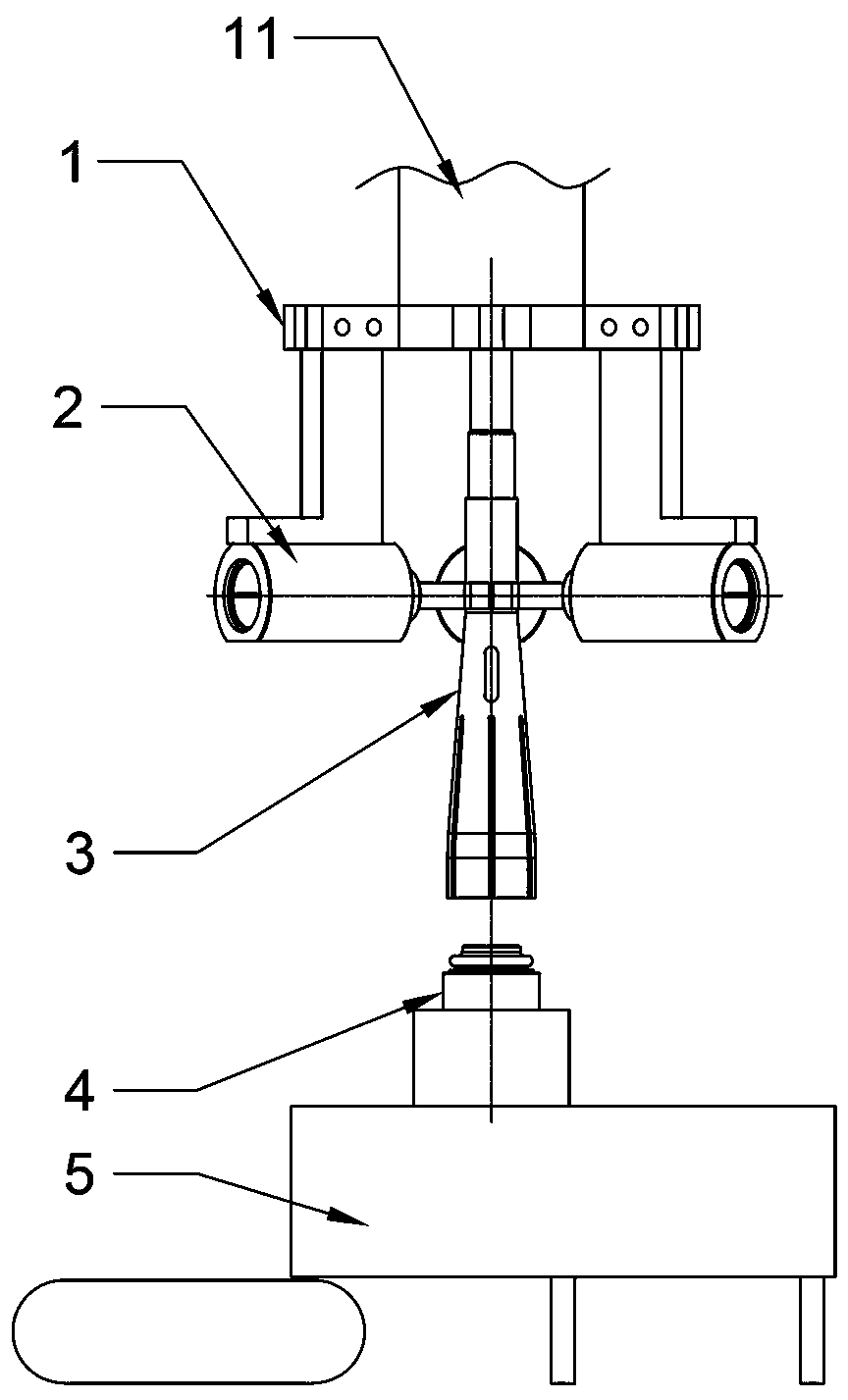

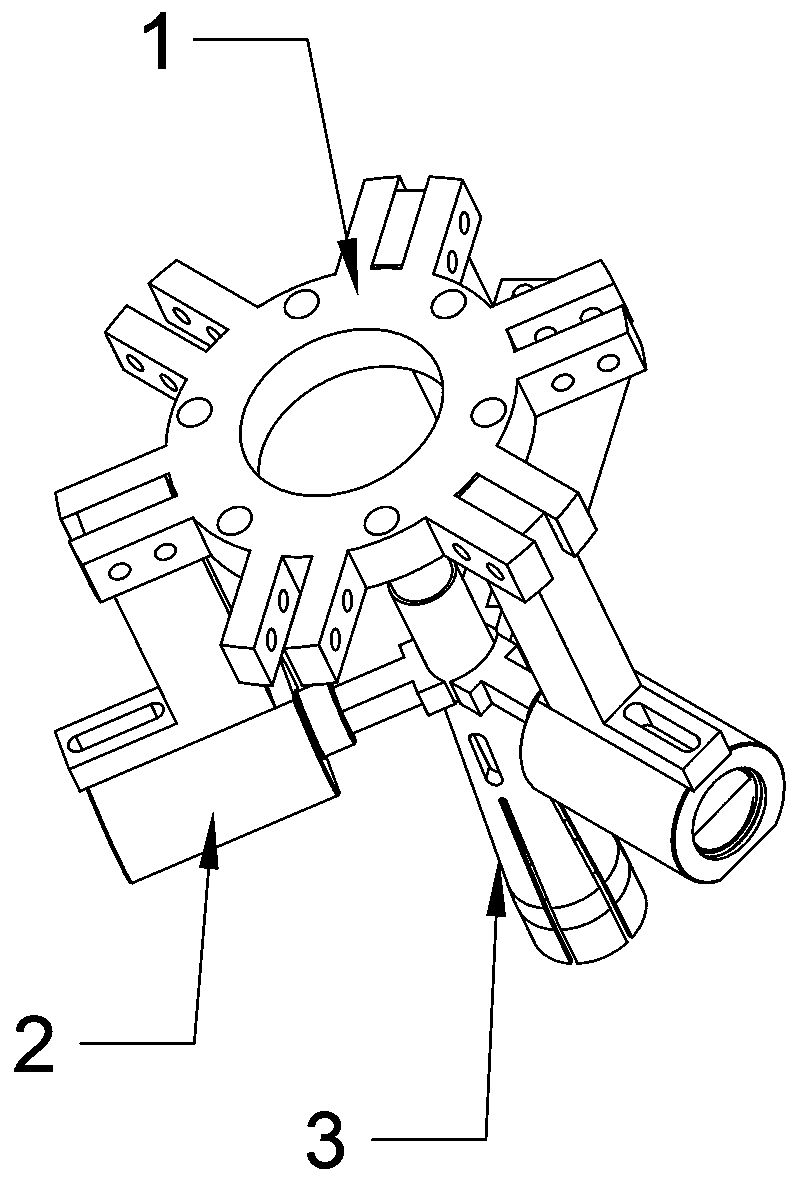

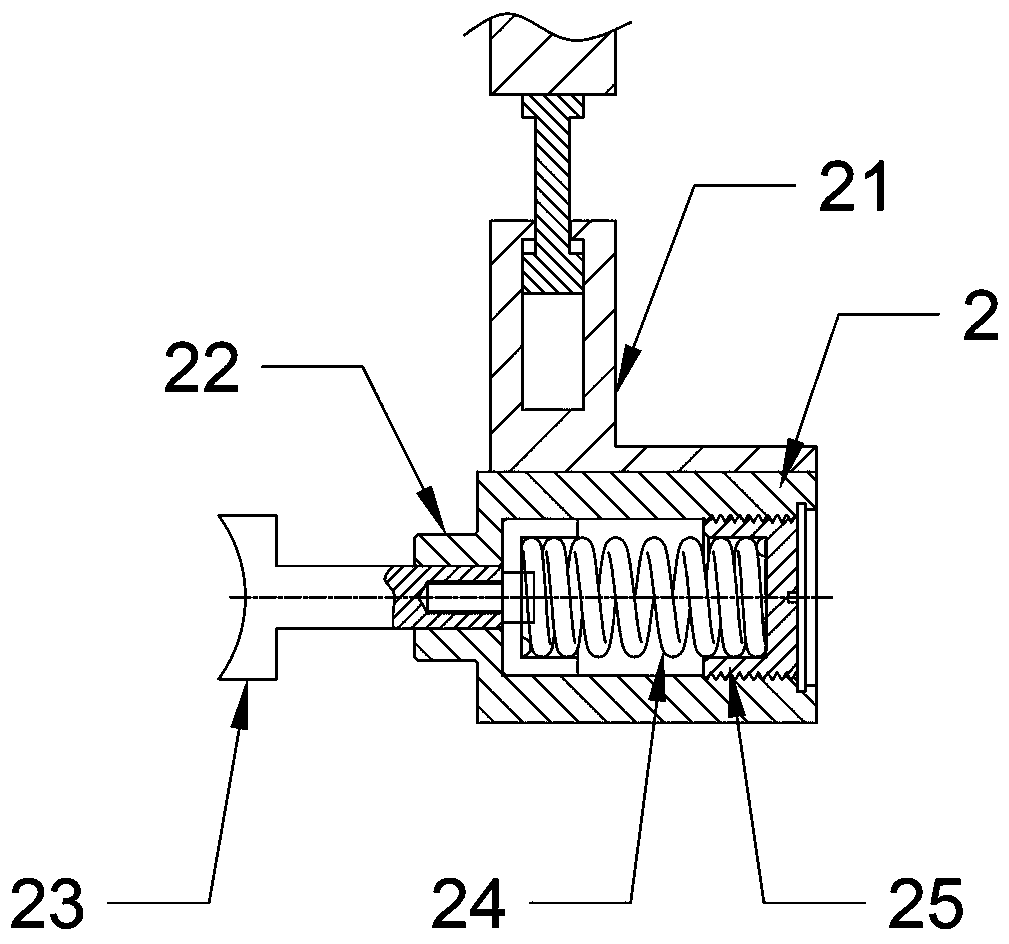

[0027] Embodiment, a kind of efficient installation method of dust cover clip, see Figure 1-7 As shown, the method includes the following steps: 1: Firstly, slide the pusher 1 directly above the clip mounting member 3, and then place the three elastic claw assemblies 2 with freely telescopic sliding arms 21 in a ring shape. Distributed fixed installation on the pusher 1, three elastic claw components 2 surround the outer surface of the clamp mounting part 3, the elastic claw components 2 are in pressure contact with the clamp mounting part 3, and then the transmission device 5 is installed on the clamp Below the installation part 3, the first conveyor belt 6 and the second conveyor belt 7 are respectively installed at both ends of the conveying device 5, and the dust cover assembly 4 is transported through the first conveyor belt 6, the conveying device 5 and the second conveyor belt 7 in sequence , After checking that the circuit installation between the various devices is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com