Environment-friendly commercial vehicle sun shield

A technology for commercial vehicles and sun visors, applied in the field of sun visors, can solve problems such as moisture absorption and easy deformation of corrugated cardboard, and achieve the effects of improving quality, easy wiping, and eliminating deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

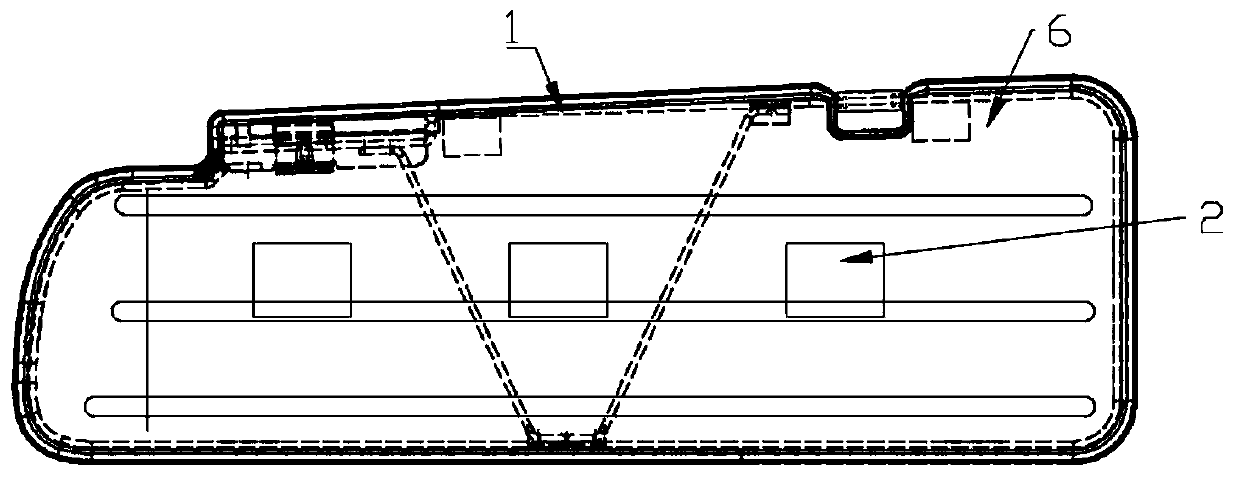

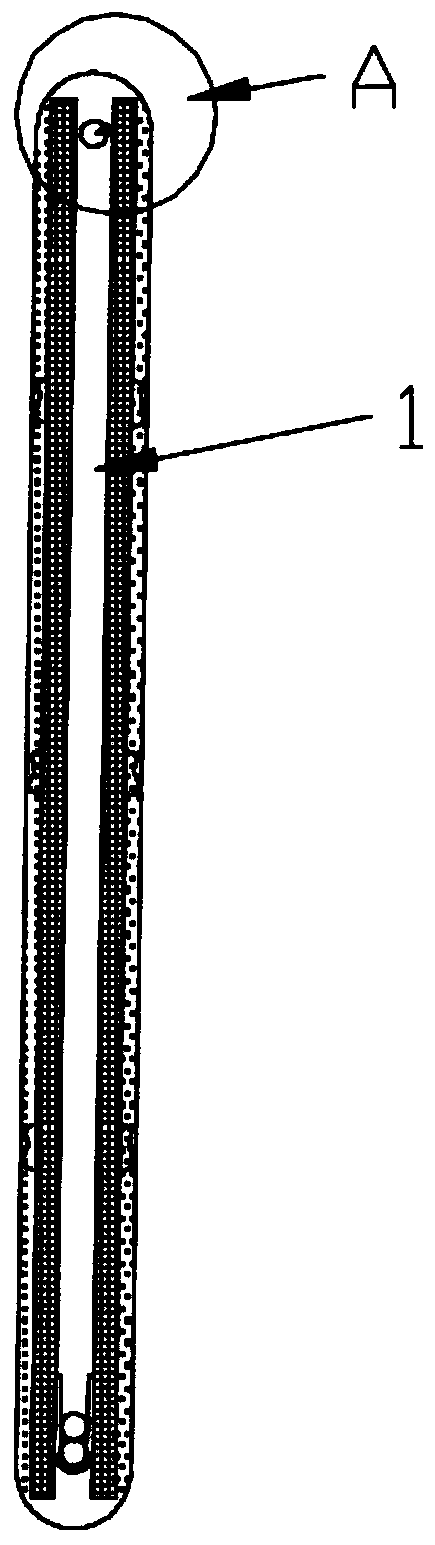

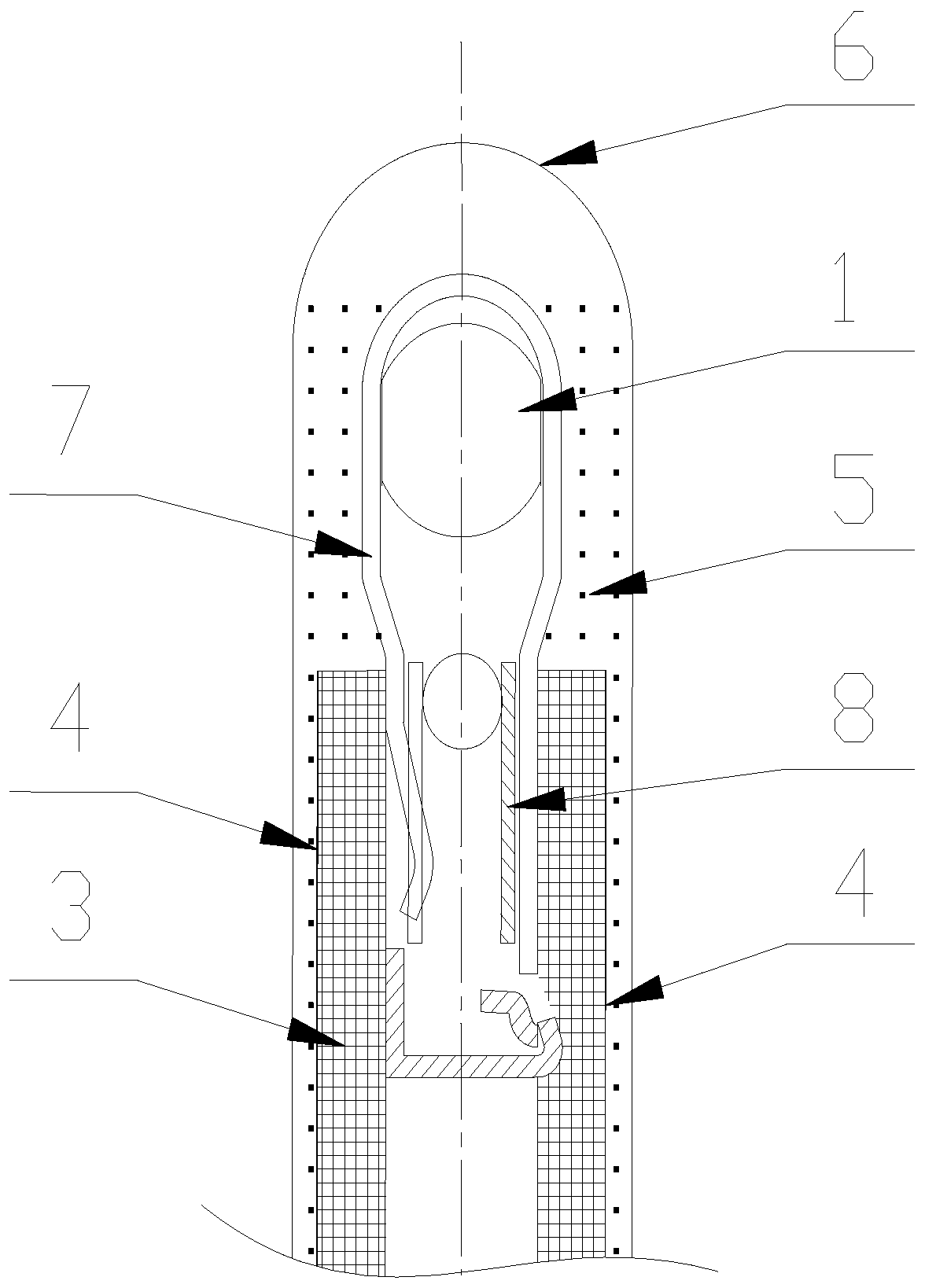

[0018] Such as Figure 1~4 As shown, in the embodiment of the present invention, a skeleton 1 is included, two PP hollow plastic plates 3 are arranged symmetrically on both sides of the skeleton 1, a fixed plate 8 and a spring clip 7 are fixedly welded inside the skeleton 1, and the skeleton 1 and the PP hollow A hot-melt adhesive filling area 2 is arranged between the plastic plates 3, and hot-melt adhesive is placed in the hot-melt adhesive filling area 2. The setting of the hot-melt adhesive filling area 2 can play the role of connecting the skeleton 1 and the PP hollow plastic plate 3, Therefore, the stability of the skeleton 1 and the PP hollow plastic board 3 is ensured. The setting of the PP hollow plastic board 3 strengthens the strength of the skeleton 1, and the size is stable, eliminating the deformation, moisture absorption and mildew quality problems that occurred when corrugated paper was used as the lining board in the past. , improving the quality of the sun vi...

Embodiment 2

[0021] Such as Figure 1~4 As shown, in the embodiment of the present invention, a skeleton 1 is included, two PP hollow plastic plates 3 are arranged symmetrically on both sides of the skeleton 1, and a fixed plate 8 and a spring clip are fixedly welded in the skeleton 1, and the skeleton 1 and the PP hollow plastic A hot-melt adhesive filling area 2 is arranged between the plates 3, and hot-melt adhesive is placed in the hot-melt adhesive filling area 2. The setting of the hot-melt adhesive filling area 2 can play the role of connecting the skeleton 1 and the PP hollow plastic plate 3, thereby The stability of the framework 1 and the PP hollow plastic board 3 is guaranteed. The setting of the PP hollow plastic board 3 strengthens the strength of the framework 1, and the size is stable, eliminating the deformation, moisture absorption and mildew quality problems that occurred when corrugated paper was used as the lining board in the past. Improved sun visor quality;

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com