Phase transformation buoyancy engine cooled by heat pipe

A technology of buoyancy and heat pipes, which is applied to special-purpose ships, warships, underwater ships, etc., can solve the problems of improving, unfavorable submersible endurance, and more power, and achieve the effects of improving response time, light weight, and reducing heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

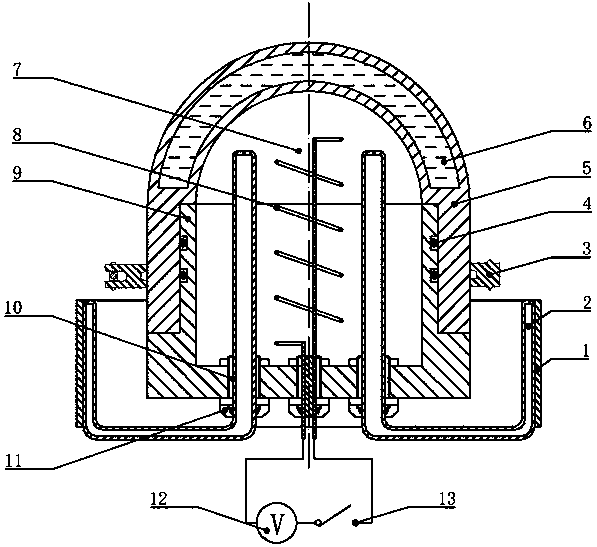

[0018] Such as figure 1 As shown, the phase-change buoyancy engine utilizing heat pipe cooling of the present invention is composed of a buoyancy generating unit and a temperature control unit: wherein the buoyancy generating unit consists of a clamp 3, a sealing ring 4, a housing 5, an insulating material 6, a phase-change material 7, Base 9, base through hole 10, watertight connector 11 constitute. The temperature control unit is composed of an annular cooling metal plate 1 , a heat pipe 2 , a heating wire 8 , a DC power supply 12 and a switch 13 .

[0019] The casing 5 and the upper part of the base 9 are assembled together, the outer side of the casing 5 is strengthened and fixed with the clamp 3, and the inner side is sealed with two sealing rings 4 for waterproofing; the casing 5 and the base 9 form a cavity inside, and the cavity is injected Filled with phase chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com