Single-sided fabric sewing process and special sewing machine thereof

A sewing machine and fabric technology, which is applied to sewing units, sewing machine components, sewing equipment, etc., can solve problems such as easy thread breakage, and achieve the effect of improving sewing strength and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

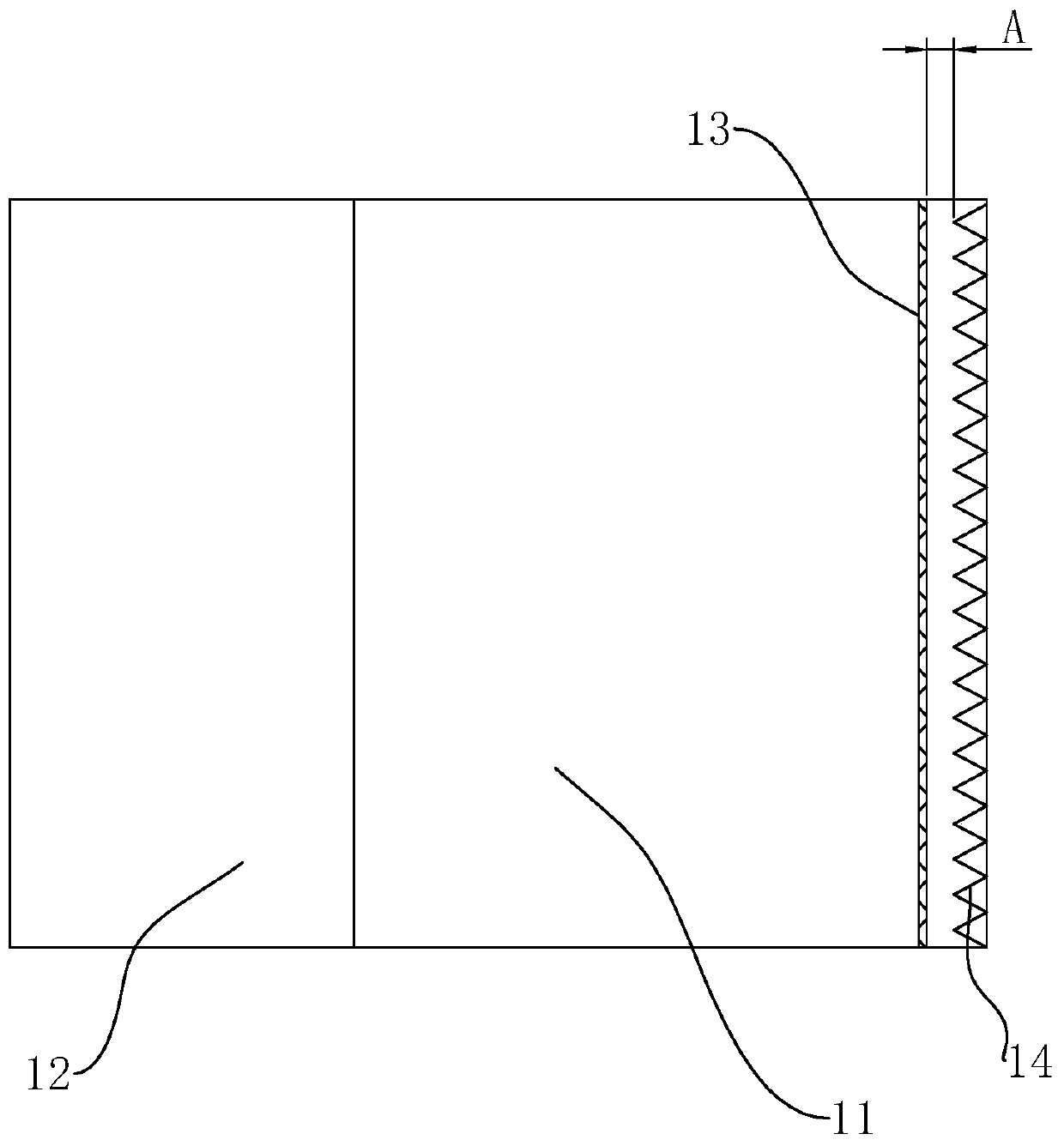

[0030] Embodiment 1: A single-sided fabric sewing process, which includes the following steps in turn: 1) stacking two layers of fabrics to be stitched together (upper layer fabric 11 and lower layer fabric 12), and aligning the stitching areas; 2) stitching Distinguish the first seaming area 13 and the second seaming area 14, the second seaming area 14 is close to the edge of the seaming area when the two layers of fabrics are stacked relative to the first seaming area 13; 3) The first seaming area 13 is sewn by a double-thread lockstitch machine system, and the second seaming area 14 is sewn with a three-thread secret copying machine. The distance A between the boundaries of the first seaming area 13 and the second seaming area 14 is less than or equal to 1 mm, generally 0.8 mm (such as figure 1 ).

[0031] The lockstitch sewing machine adopts Xinjia single-needle double-thread lockstitch sewing machine, and the three-thread close copying machine is used to sew with Bamo BM...

Embodiment 2

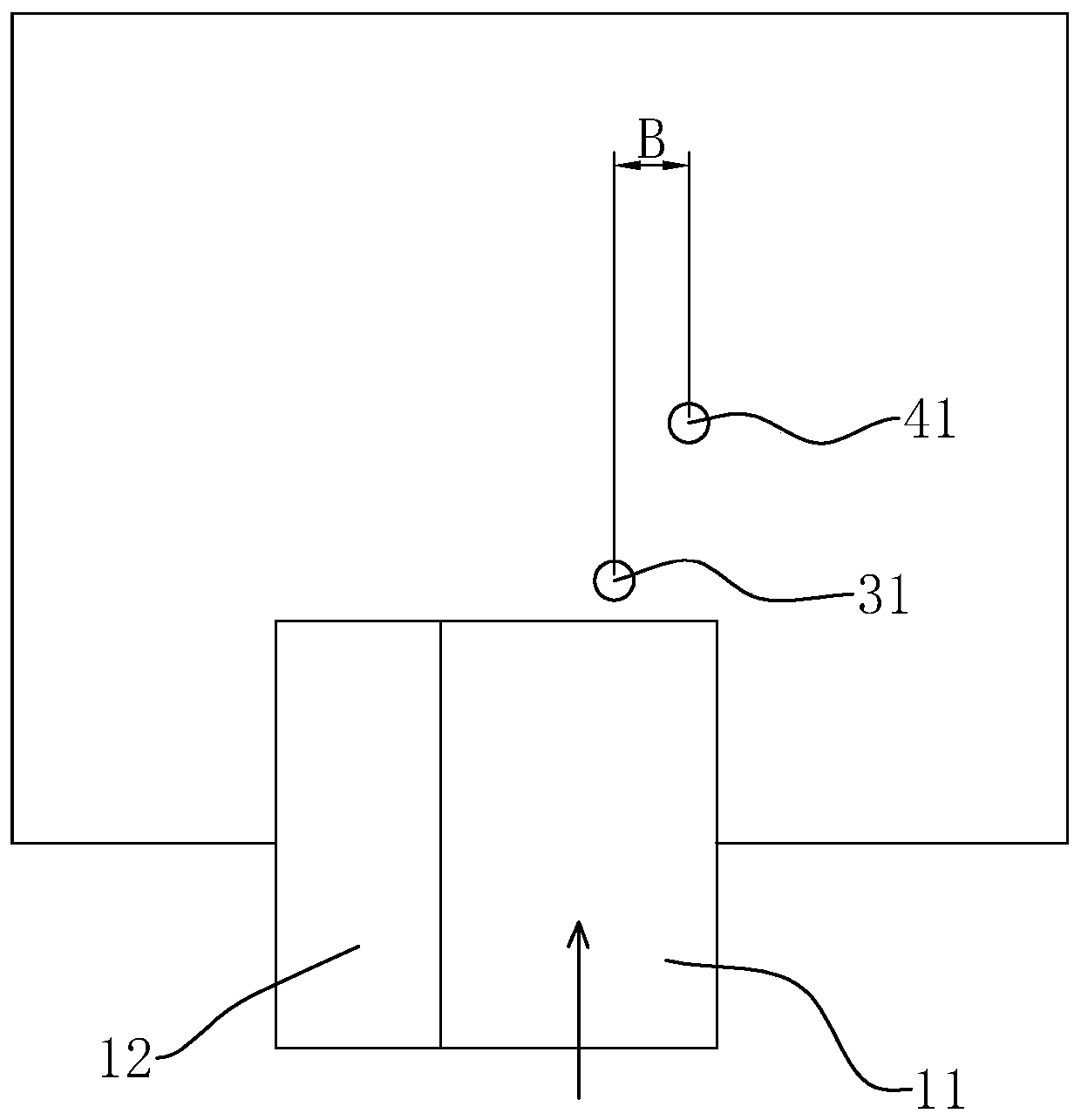

[0032] Embodiment 2: A sewing machine dedicated to the sewing process of fabrics used on one side, including a machine platform 2, a lockstitch body 3 and a secret copy body 4 installed on the machine platform 2. The lockstitch body 3 and the secret copy body 4 are arranged in a staggered manner along the forward direction of the fabric, and the distance B between the sewing needle 1 31 of the lockstitch body 3 and the suture needle 2 42 of the secret copy body 4 is 0.8 in the direction perpendicular to the forward direction of the fabric. mm (eg figure 2 ).

[0033] When sewing the cloth, the alignment edge of the upper fabric 11 and the lower fabric 12 is positioned below the sewing needle 2 42 , and the sewing needle 1 31 is located inside relative to the sewing needle 2 42 .

Embodiment 3

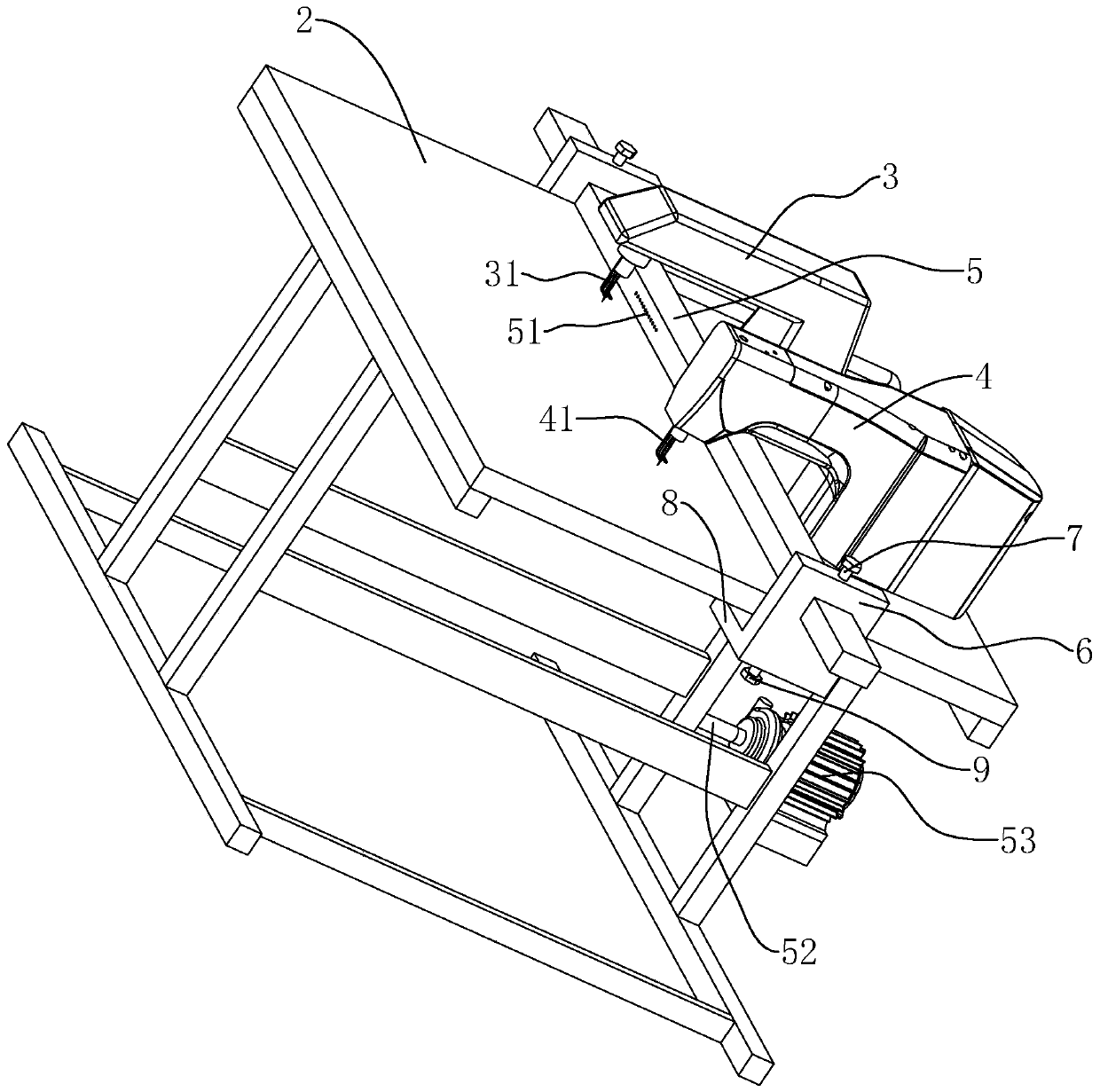

[0034] Embodiment 3: a kind of sewing machine dedicated to the sewing process of fabrics used on one side, such as image 3 , including a machine platform 2, a lockstitch body 3 installed on the machine platform 2 and a secret copy body 4, the secret copy body 4 is closer to the entry end of the fabric than the lockstitch body 3. Lockstitch body 3 and close copy body 4 are arranged staggered along the direction that fabric advances, and the sewing needle one 31 of lockstitch body 3 and the spacing of guide strip 5 are less than the spacing of sewing needle two 42 of close copy body 4 and guide strip 5.

[0035] A guide bar 5 is fixed on the machine platform 2, and the guide bar 5 extends along the advancing direction of the fabric. The inside of the guide bar 5 is provided with a cavity, and the side of the guide bar 5 close to the fabric is provided with an air hole 51, the air hole 51 communicates with the cavity, the other side of the guide bar 5 is connected to the air pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com