Charging system for well-drilling fluid lubricant

A feeding system and drilling fluid technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc., can solve problems such as excessive lubricant addition and unsatisfactory lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

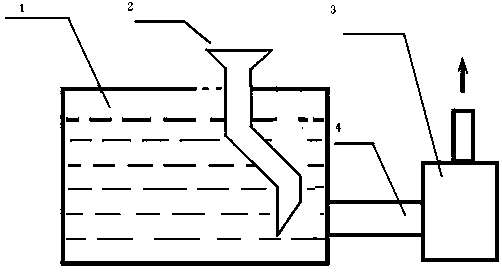

[0012] refer to figure 1 , a feeding system for a drilling fluid lubricant, comprising a drilling fluid tank 1, a mud pump 3 and a pipeline 4 connected between the drilling fluid tank and the mud pump, a lubricant feeding funnel 2 is set in the drilling fluid tank 1, and the lubricant The discharge port of the feeding funnel 2 is adjacent to the drilling fluid outlet of the drilling fluid tank.

[0013] Further, the lower part of the lubricant feeding funnel is S-shaped.

[0014] Furthermore, the outlet of the lubricant feeding funnel is an outlet on an inclined plane, and the outlet is opposite to the drilling fluid outlet of the drilling fluid tank.

[0015] The working flow of the device is: when the drilling friction needs to be reduced, the drilling fluid lubricant is added from the lubricant feeding funnel 2 . The high-concentration lubricant is pumped into the wellbore, sprayed out from the drill bit, and adsorbed on the porous rock on the well wall in large quantitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com