A kind of treatment method and device of sulfur-containing flue gas

A treatment method and flue gas technology are applied in the field of sulfur-containing flue gas treatment methods and devices, which can solve the problems of long treatment process, complicated treatment process, and high treatment energy consumption, and achieve low treatment cost, high carbon sequestration efficiency, and high carbon removal efficiency. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Pass the sulfur-containing flue gas into the desulfurization reactor, and use the nitrite solution as the absorbent to remove SO 2 , so that SO 2 The removal rate is greater than 95%.

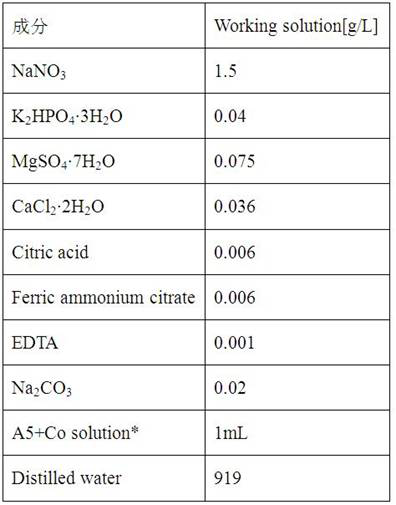

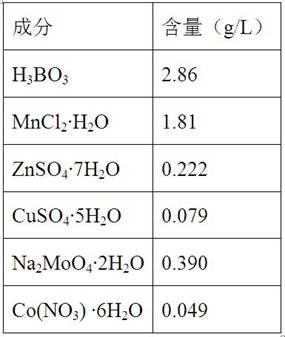

[0042] (2) In a 10L photobioreactor, add the prepared cellulosic algae SS-B7 seed liquid and microalgae medium, the amount of microalgae medium added is 6L, and the amount of seed liquid added is 0.9L. CO in desulfurization flue gas 2 The content of NO is 5v%, the NO content is 0.03v%, and the ventilation volume is 0.5vvm. The light intensity for cultivation was 5000Lux, the cultivation temperature was 25°C, the light cycle was 24h, and the light-dark time ratio was 14:10. In the collected exhaust gas, CO 2 The removal rate is 85%, and the NO removal rate is 35%.

[0043] (3) After 7 days of culture, microalgae cells and filtrate were harvested by centrifugation. Determine dry cell weight and lipid content. After vacuum freeze-drying at -60°C to constant weight, the dry weight...

Embodiment 2

[0046] (1) Pass the sulfur-containing flue gas into the desulfurization reactor, and use the nitrite solution as the absorbent to remove SO 2 , so that SO 2 The removal rate is greater than 95%.

[0047] (2) In a 10L photobioreactor, add the prepared cellulosic algae SS-B7 seed liquid and microalgae medium, the amount of microalgae medium added is 6L, and the amount of seed liquid added is 1.0L. CO in desulfurization flue gas 2 The content of NO is 10v%, the NO content is 0.05v%, and the ventilation volume is 0.5vvm. The light intensity for cultivation was 5000Lux, the cultivation temperature was 25°C, the light cycle was 24h, and the light-dark time ratio was 14:10. In the collected exhaust gas, CO 2 The removal rate was 76%, and the NO removal rate was 31%.

[0048] (3) After 8 days of culture, microalgae cells and filtrate were harvested by centrifugation. Determine dry cell weight and lipid content. After vacuum freeze-drying at -60°C to constant weight, the dry wei...

Embodiment 3

[0051] (1) Pass the sulfur-containing flue gas into the desulfurization reactor, and use the nitrite solution as the absorbent to remove SO 2 , so that SO 2 The removal rate is greater than 95%.

[0052] (2) In a 10L photobioreactor, add the prepared cellulosic algae SS-B7 seed solution and microalgae medium, the amount of microalgae medium added is 6L, and the amount of seed solution added is 1.2L. CO in desulfurization flue gas 2 The content of NO is 40v%, the NO content is 0.05v%, and the ventilation volume is 0.25vvm. The light intensity for cultivation was 5000Lux, the cultivation temperature was 25°C, the light cycle was 24h, and the light-dark time ratio was 14:10. In the collected exhaust gas, CO 2 The removal rate is 56%, and the NO removal rate is 22%.

[0053] (3) After 8 days of culture, microalgae cells and filtrate were harvested by centrifugation. Determine dry cell weight and lipid content. After vacuum freeze-drying at -60°C to constant weight, the dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com