Dual-motor drive assembly clamping jaw capable of simultaneously stretching out and drawing back in two-way mode

A dual-motor drive, assembling clip technology, applied in the direction of claw arm, chuck, manipulator, etc., can solve the problems of inaccurate installation position, high labor intensity, increase production cost, etc., achieve fast response, simple structure, telescopic wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

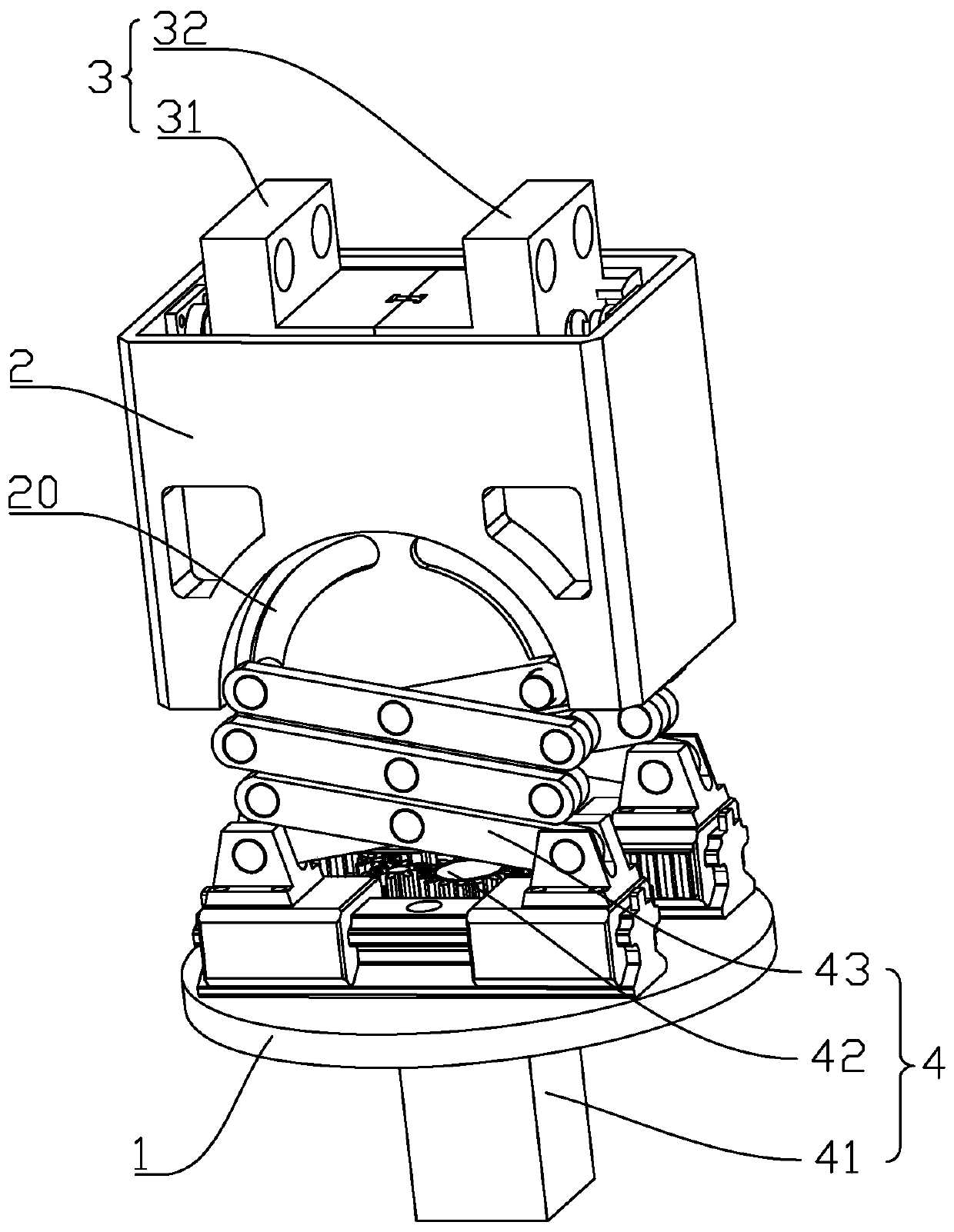

[0021] refer to Figure 1 to Figure 6 , a dual-motor-driven assembly jaw that can be retracted in both directions at the same time, including:

[0022] The lower housing base 1 as a load-bearing structure;

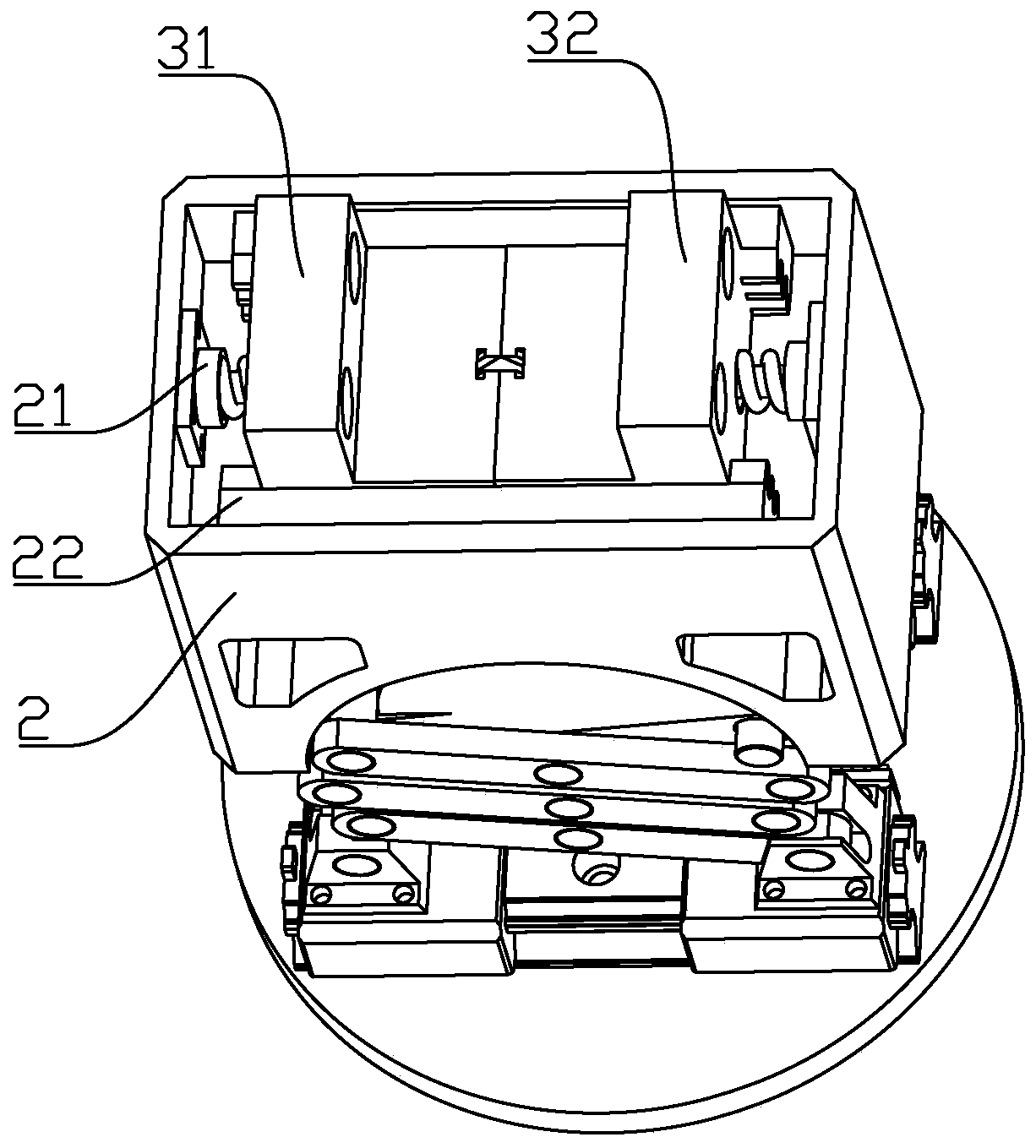

[0023] An upper housing base 2 located above the lower housing base 1;

[0024] The jaw member 3 provided on the upper housing base 2 includes two left jaws 31 and right jaws 32 corresponding to each other and used to clamp the workpiece;

[0025] The claw opening member provided on the upper housing base 2 is set in conjunction with the jaw member 3 and is used to implement the opening and closing actions of the left jaw 31 and the right jaw 32;

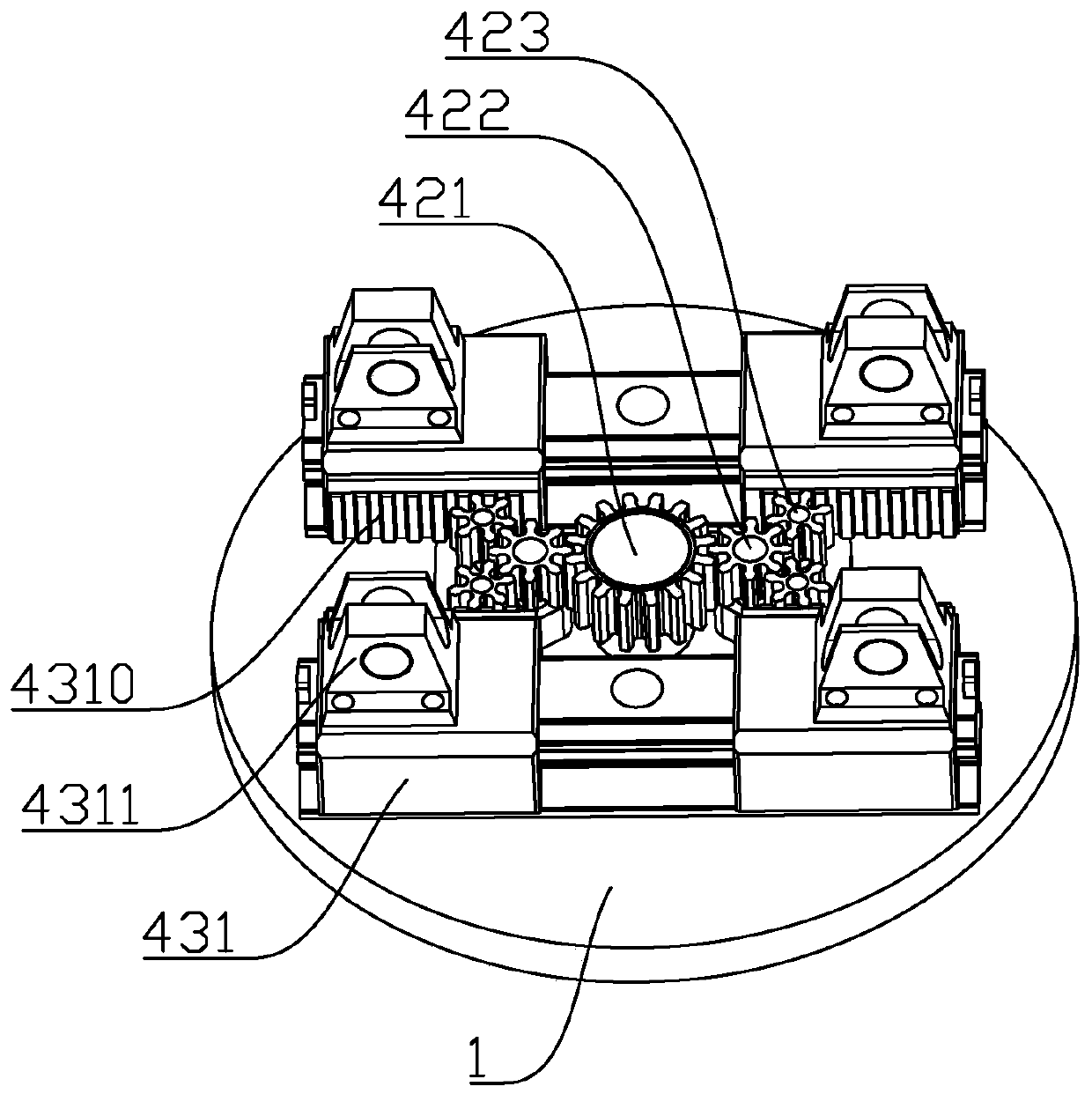

[0026] And a height adjustment member 4 provided on the lower housing base 1, which is provided in conjunction with the jaw member 3 and used to adjust the height of the jaw member 3;

[0027] The height ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com