Tensioning device of steel wire rope of bulk machine

A tensioning device and wire rope technology, applied in the direction of hoisting device, spring mechanism, etc., can solve problems such as over-tightening, affecting normal cutting, wire rope slack, etc., to prolong observation and operation time, avoid mechanical damage, prolong The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

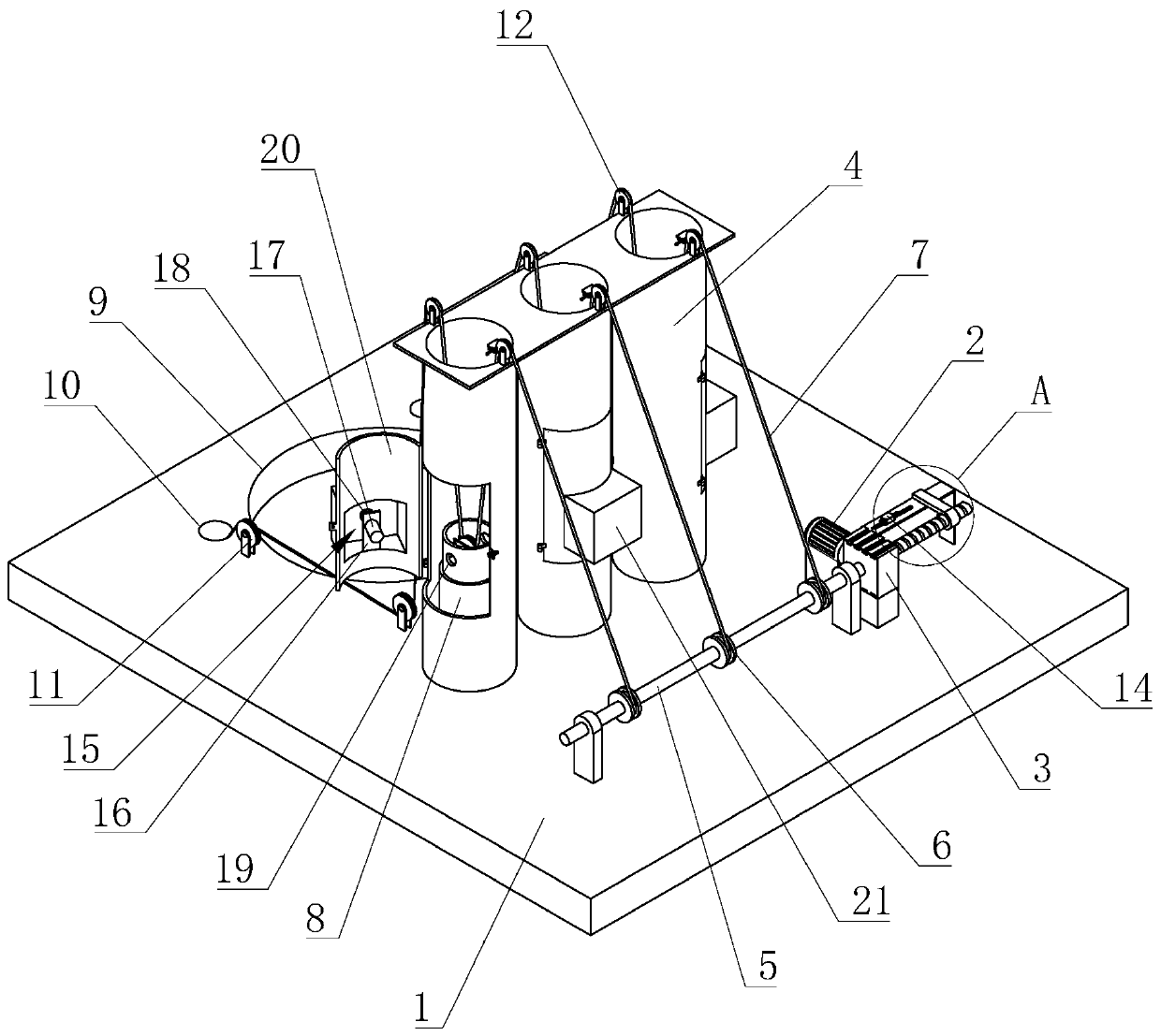

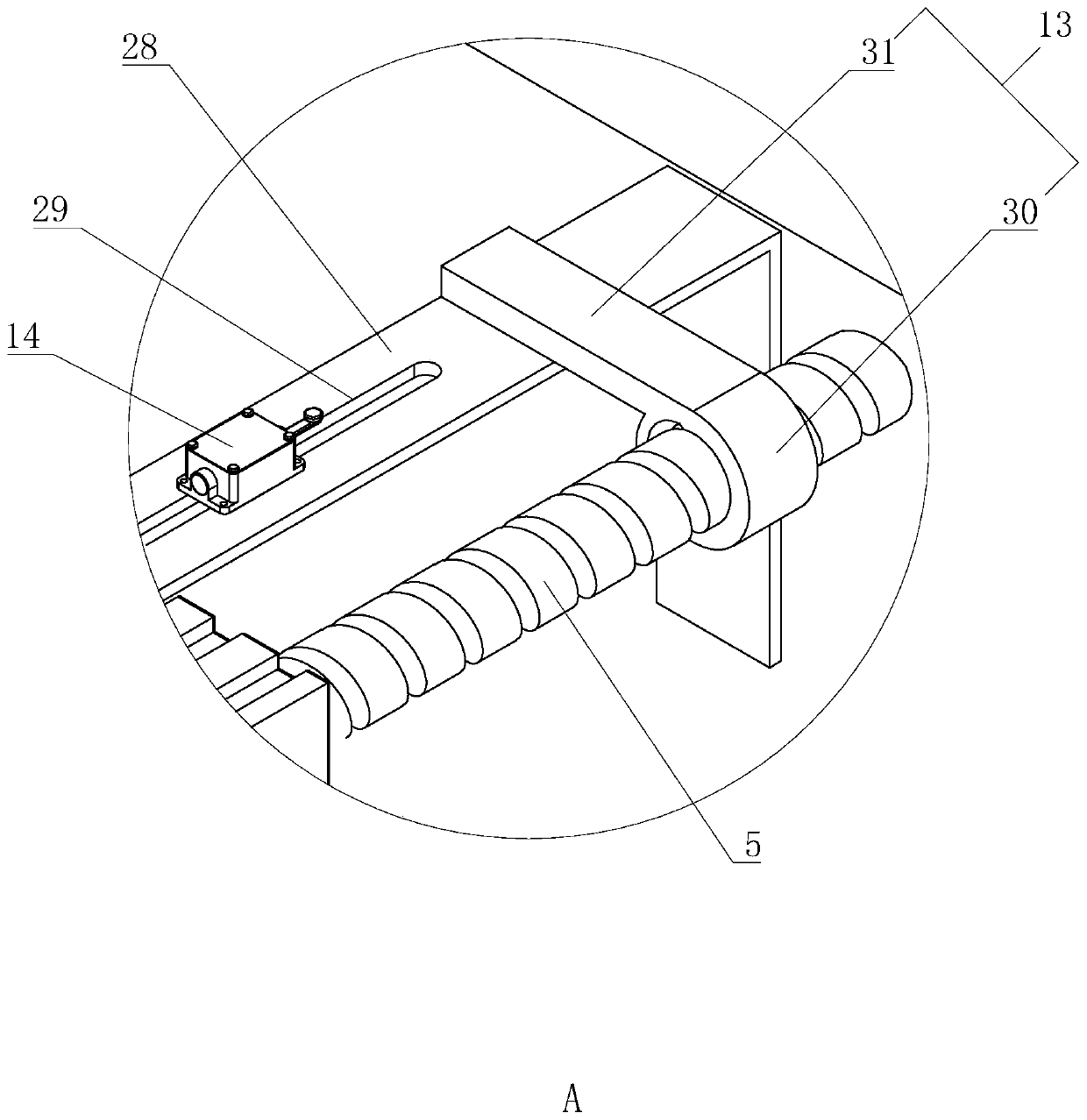

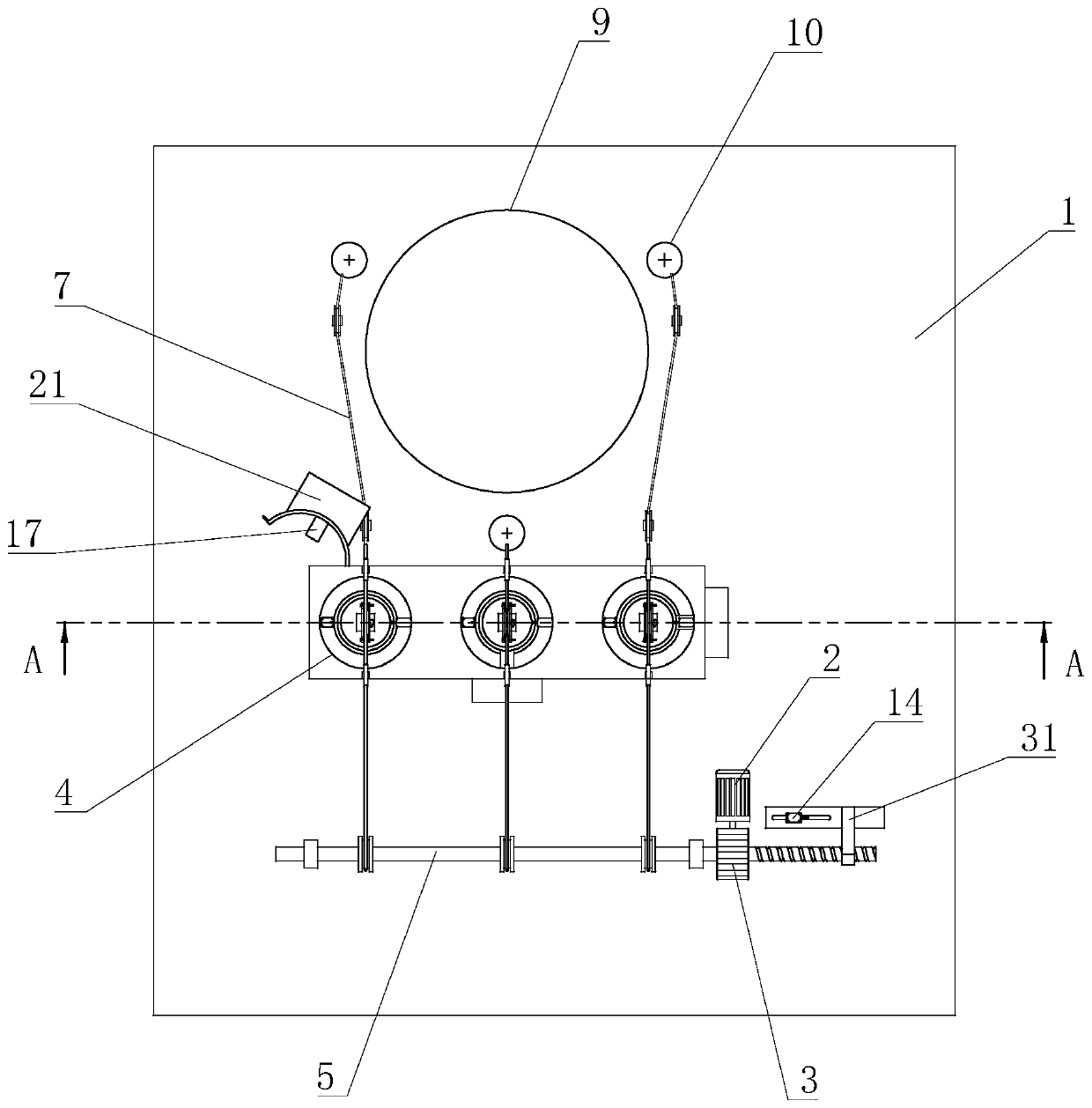

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] refer to figure 1 , is a tensioning device for a wire rope 7 disclosed in the present invention, comprising a base 1, three hollow columns 4 vertically fixed on the base 1, a drive motor 2 and a reducer 3 fixedly installed on the base 1. Three hollow columns 4 are arranged in a straight line and equidistant on the base 1, the drive motor 2 is fixedly installed on the base 1 and the output end is connected to the reducer 3, the output shaft of the reducer 3 is fixedly connected to the central rotating shaft 5, and the central rotating shaft 5 is along the The arrangement direction of the three hollow columns 4 extends. Three winding sheaves 6 are fixed on the central rotating shaft 5 , the central axes of the three winding sheaves 6 are parallel to the central rotating shaft 5 and the positions of the three winding sheaves 6 correspond to the three hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com