Two rotations and one translation large stroke uncoupled large hollow parallel piezoelectric micro-motion platform

A micro-motion platform, no coupling technology, applied in the field of micro-displacement mechanism, two rotations and one translation, large stroke without coupling, large hollow parallel piezoelectric micro-motion platform, which can solve the problems of large platform structure, small platform displacement stroke, and non-compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

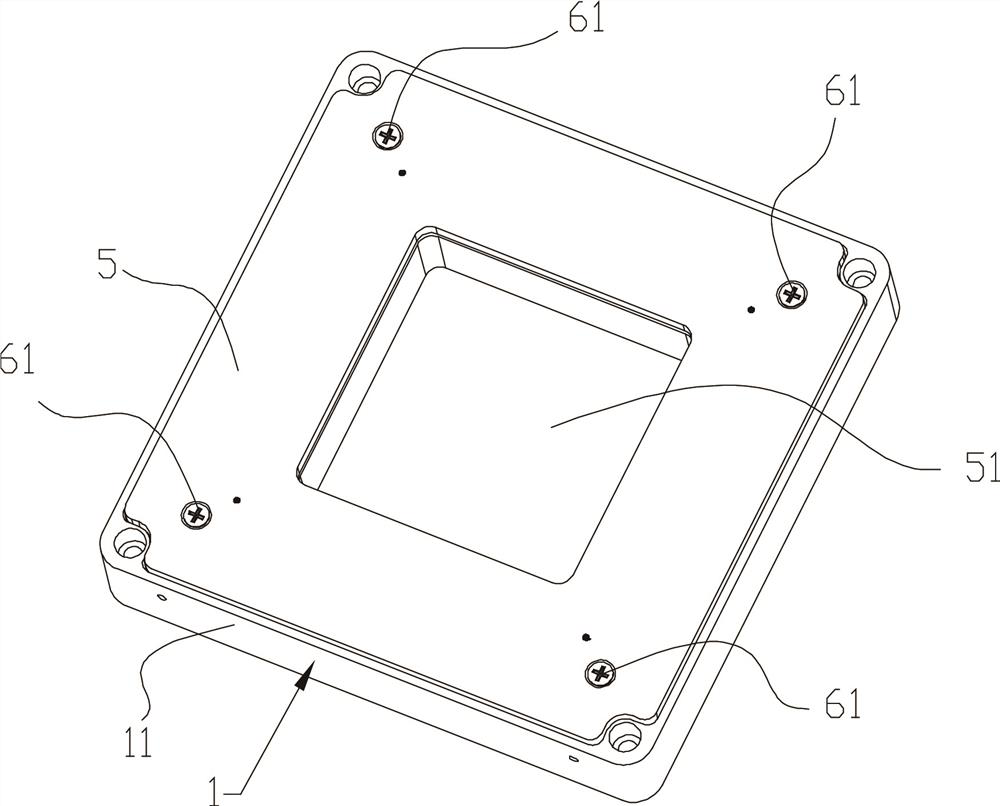

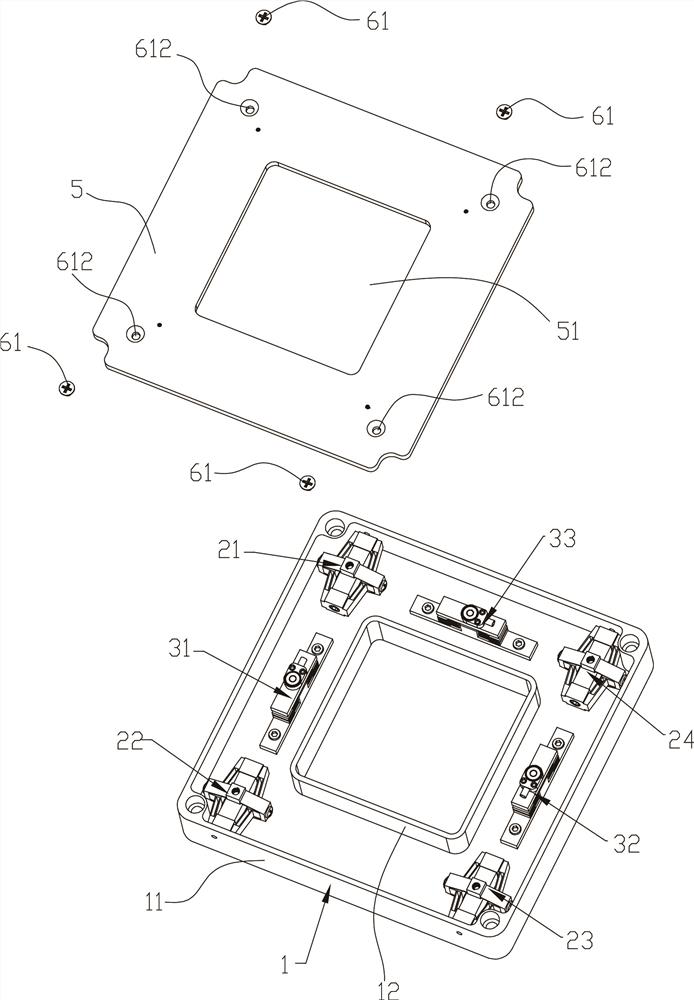

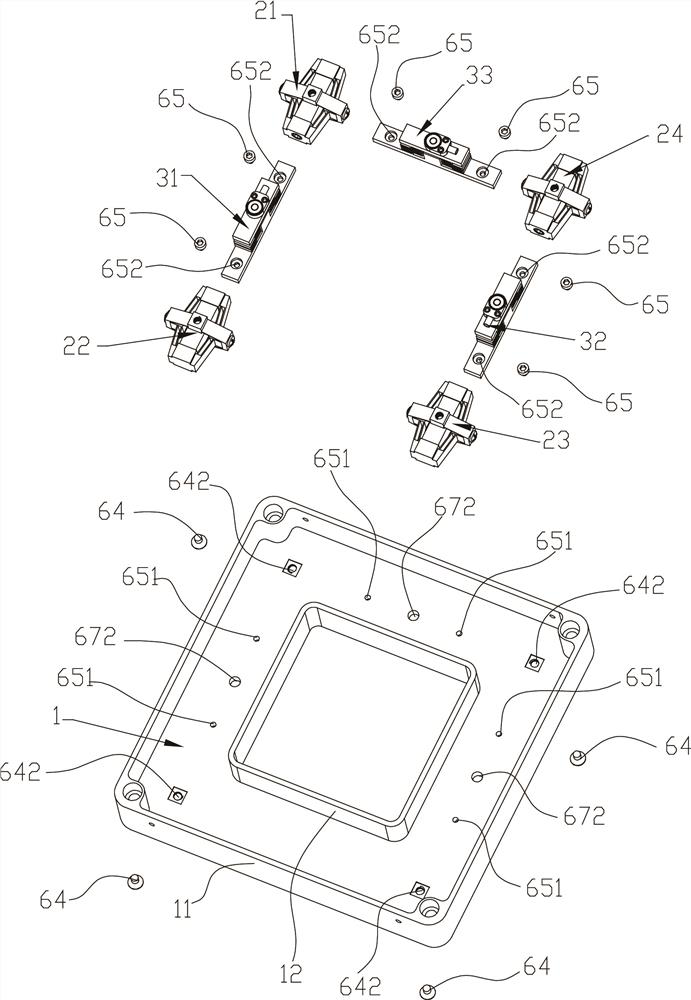

[0035] Figure 1 to Figure 9 It is a structural schematic diagram of the present invention, wherein the reference signs are: base 1, enclosure 11, tubular body 12, first drive unit 21, second drive unit 22, third drive unit 23, fourth drive unit 24, base Seat 3, first plate body 301, flexible folding beam 302, second plate body 303, sensor probe 304, first displacement sensor 31, second displacement sensor 32, third displacement sensor 33, primary bridge amplification mechanism 41, Secondary bridge amplifying mechanism 42, piezoelectric actuator 43, first rigid part 411, second rigid part 412, third rigid part 413, fourth rigid part 414, first flexible sheet 415, second flexible sheet 416, The fifth rigid part 421, the sixth rigid part 422, the seventh rigid part 423, the eighth rigid part 424, the third flexible thin plate 425, the moving tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com