Flat filament brush-making head

A flat wire and hair head technology, applied in the field of brush hair planting equipment, can solve the problems of complex structure, many fault points and poor reliability of the hair plant head, and achieve the effects of simple structure, many fault points, and few fault points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

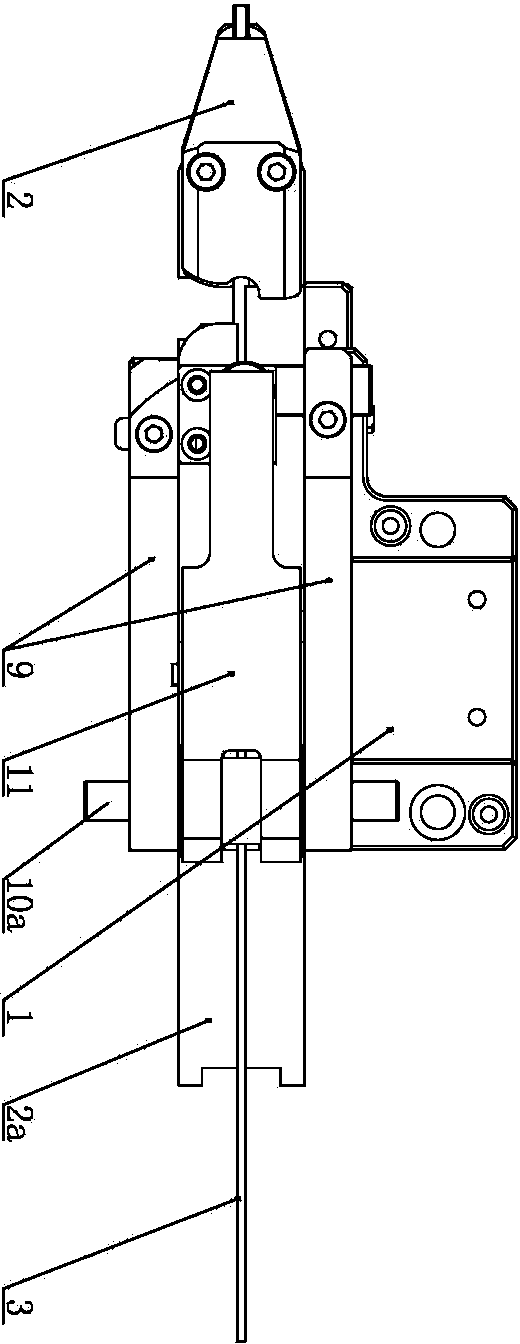

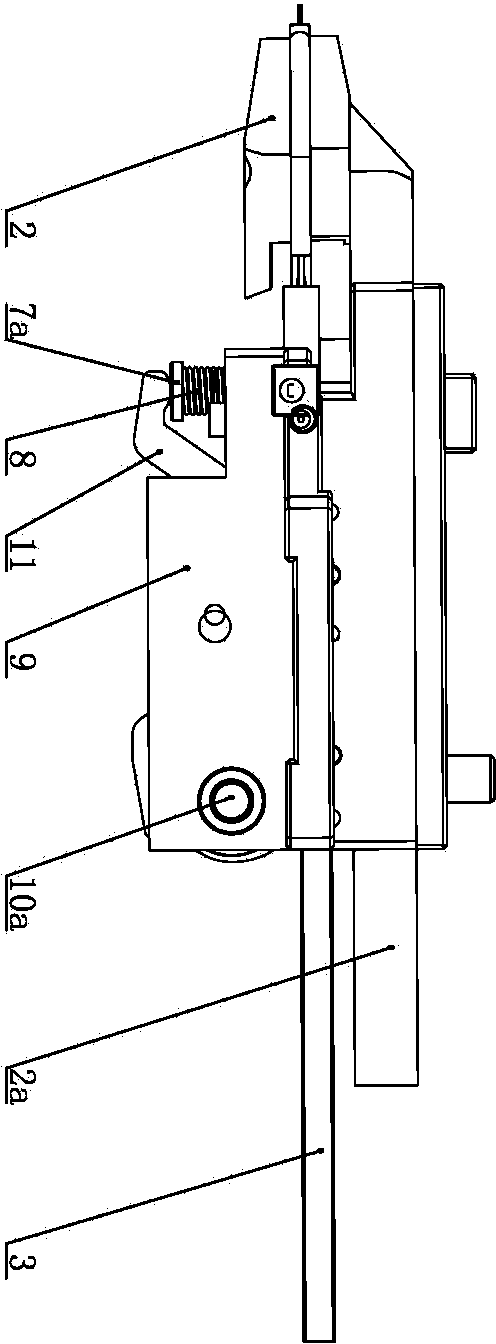

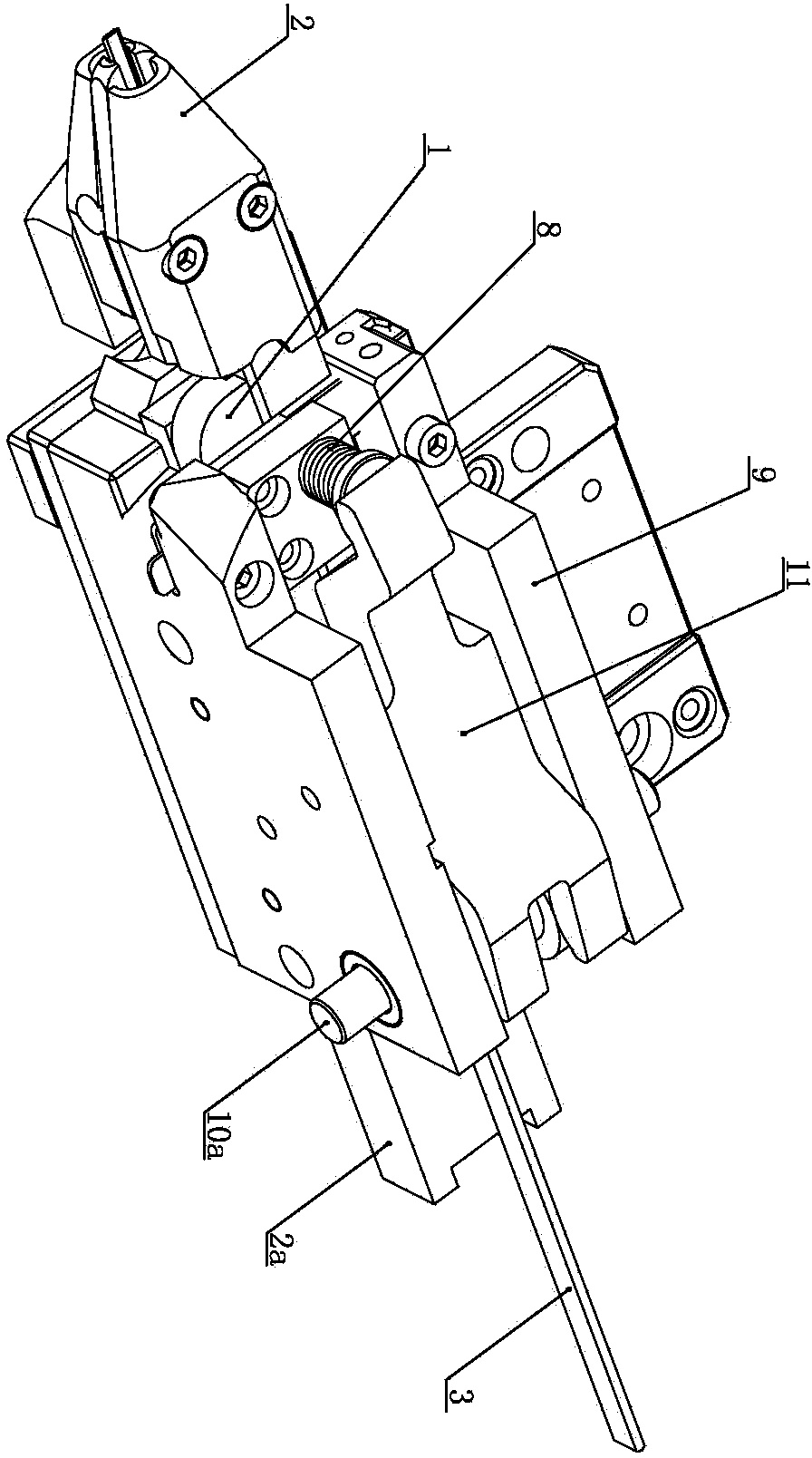

[0020] Such as Figure 1 to Figure 8 As shown, the flat wire tufting head of the present invention includes a fixed seat 1 and a nozzle 2, the nozzle 2 is fixed on the nozzle guide rod 2a, and the nozzle guide rod 2a can move back and forth in the nozzle guide groove of the holder 1, There are punching needles, shredding fixed knife seat 4 and shredding moving knife seat 6 behind the nozzle 2, the punching needle is located in the punching needle guide groove and the front end of the punching needle is facing the center channel of the nozzle 2, and the shredding fixed knife seat 4 and the shredded moving knife seat 6 are installed on the fixed seat 1, the shredded fixed knife seat 4 is fixed with a shredded fixed knife 5, and the shredded fixed knife 5 is provided with a flat wire guide groove 5a, and the flat wire guide groove 5a The center line is perpendicular to the center line of the center hole of the hair nozzle. The moving knife 7 for shredding can slide up and down in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com