External structured system composition for liquid detergent, and liquid detergent

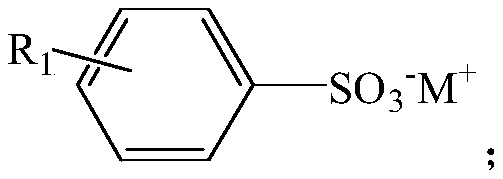

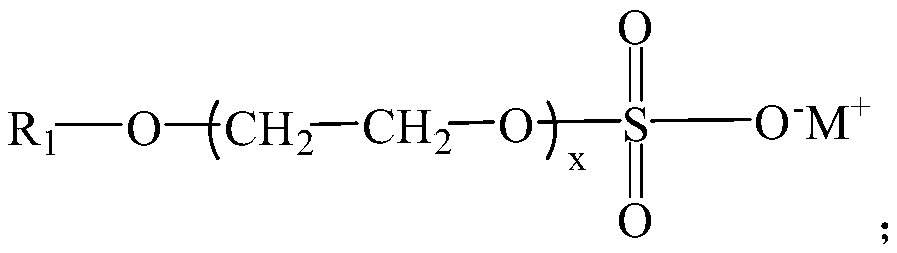

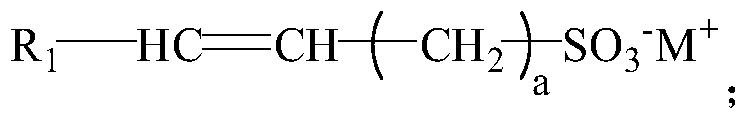

A technology of external structuring and liquid detergent, which is applied in the direction of detergent composition, washing composition bleaching agent, detergent compounding agent, etc., and can solve the problem of affecting the emulsifying ability of anionic emulsifiers, affecting the external structuring performance, and the emulsifying ability is not as good as and other problems, to achieve the effect of high stability, good suspension ability and high suspension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0195] The external structuring system composition embodiment 1-6 of above-mentioned table 2, its preparation method is:

[0196] A) Under stirring, put surfactant (LAS), alkaline agent (liquid caustic soda), pH stabilizer (sodium citrate) and alkylarylsulfonic acid solubilizer (2,4-xylenesulfonic acid) into the reaction kettle in sequence Sodium acid, sodium p-toluenesulfonate or sodium cumenesulfonate), and the pH of the mixture in the reactor is adjusted to 6.0~10, preferably 7~8.5 with a pH regulator (citric acid);

[0197] B) Then heat to 80°C-95°C, preferably 90°C-95°C, then add 12-hydroxy-octearic acid triglyceride, and at this temperature, stir until all 12-hydroxy-octearic acid triglyceride Esters are fully emulsified;

[0198] C) cooling the mixture rapidly to 55°C-80°C, and keeping it at this temperature for 5 minutes-300 minutes, preferably 60 minutes-120 minutes;

[0199] D) Finally, slowly lower the temperature to below 40°C, preferably room temperature. The e...

Embodiment 1

[0210] Example 1: Step A added sodium 2,4-xylenesulfonate (0.5% added), and mixed 6 parts of the prepared external structuring system with 93 parts of "1# base liquid" and 1 part of pure water;

Embodiment 2

[0211] Example 2: In step A, sodium 2,4-xylenesulfonate (0.5% added) was added, and 6 parts of the prepared external structuring system were mixed with 93 parts of "2# base liquid" and 1 part of pure water.

[0212] Table 3 Tests of Exterior Structuring System Compositions

[0213]

[0214] Obviously, sodium 2,4-xylene sulfonate is fed preferentially over 12-hydroxy-octearic acid triglyceride in order to have an effect on the crystallization behavior of 12-hydroxy-octearic acid triglyceride, that is, to enhance the structure of liquid detergents ability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com