Humidity driver based on polyaspartic acid nanofiber membrane and preparation method thereof

A nanofiber membrane, polyaspartic acid technology, applied in the direction of fiber type, fiber processing, textile and papermaking, etc., can solve the problems of poor sensitivity, slow response and high preparation cost of the humidity driver, and achieve good humidity responsiveness and response. Fast and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

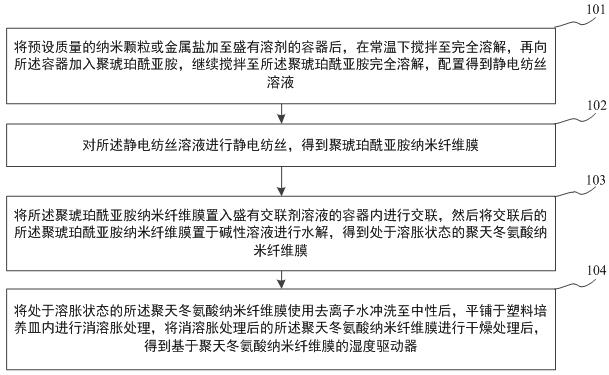

[0031] figure 1 It is a method flow chart of a method for preparing a humidity driver based on a polyaspartic acid nanofiber membrane shown according to an exemplary embodiment, such as figure 1 Shown, the preparation method of the humidity driver based on polyaspartic acid nanofiber membrane comprises:

[0032] Step 101: After adding a preset mass of nanoparticles or metal salts to a container containing a solvent, stir at room temperature until completely dissolved, then add polysuccinimide to the container, and continue stirring until the polysuccinimide The imine was completely dissolved and configured to obtain an electrospinning solution.

[0033] Step 102: Electrospinning the electrospinning solution to obtain a polysuccinimide nanofiber membrane.

[0034] Step 103: placing the polysuccinimide nanofiber membrane in a container containing a crosslinking agent solution for crosslinking, and then placing the crosslinked polysuccinimide nanofiber membrane in an alkaline s...

Embodiment 1

[0049] (1) Change CH 3 After adding COOAg to the container containing N,N-dimethylformamide, stir at room temperature until CH 3COOAg is completely dissolved, then adds polysuccinimide to the container, and continues to stir until the polysuccinimide is completely dissolved, and is configured to obtain an electrospinning solution. The mass of polysuccinimide in the electrospinning solution is The concentration is 30%, CH 3 The content of COOAg is 10% of the mass of polysuccinimide.

[0050] (2) Electrospinning the electrospinning solution to obtain a polysuccinimide nanofiber membrane.

[0051] (3) Put the polysuccinimide nanofiber membrane into a container filled with 0.3 mol / L ethylenediamine solution for crosslinking, and then place the crosslinked polysuccinimide nanofiber membrane in Hydrolysis is carried out in 0.11mol / L sodium hydroxide solution to obtain a polyaspartic acid nanofiber membrane in a swollen state.

[0052] (4) Rinse the polyaspartic acid nanofiber me...

Embodiment 2

[0054] (1) SiO 2 After adding the nanoparticles to the container containing N,N-dimethylformamide, stir at room temperature until SiO 2 The nanoparticles are completely dissolved, and then polysuccinimide is added to the container, and the stirring is continued until the polysuccinimide is completely dissolved, and an electrospinning solution is obtained. The polysuccinimide in the electrospinning solution is The mass concentration is 30%, CH 3 The content of COOAg is 3% of the mass of polysuccinimide.

[0055] (2) Electrospinning the electrospinning solution to obtain a polysuccinimide nanofiber membrane.

[0056] (3) Put the polysuccinimide nanofiber membrane into a container filled with 0.5 mol / L ethylenediamine solution for crosslinking, and then place the crosslinked polysuccinimide nanofiber membrane in Hydrolysis is carried out in 0.5 mol / L sodium hydroxide solution to obtain a polyaspartic acid nanofiber membrane in a swollen state.

[0057] (4) Rinse the polyaspar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap