A kind of resistive polymer humidity sensitive material and preparation method thereof

A moisture-sensitive material and resistance-type technology, which is applied in the analysis of materials, material analysis through electromagnetic means, and material resistance, can solve the problems of easy slip loss, hindering popularization and application, high humidity resistance and poor long-term stability, etc. Achieve high humidity resistance, good long-term stability, good humidity response, and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

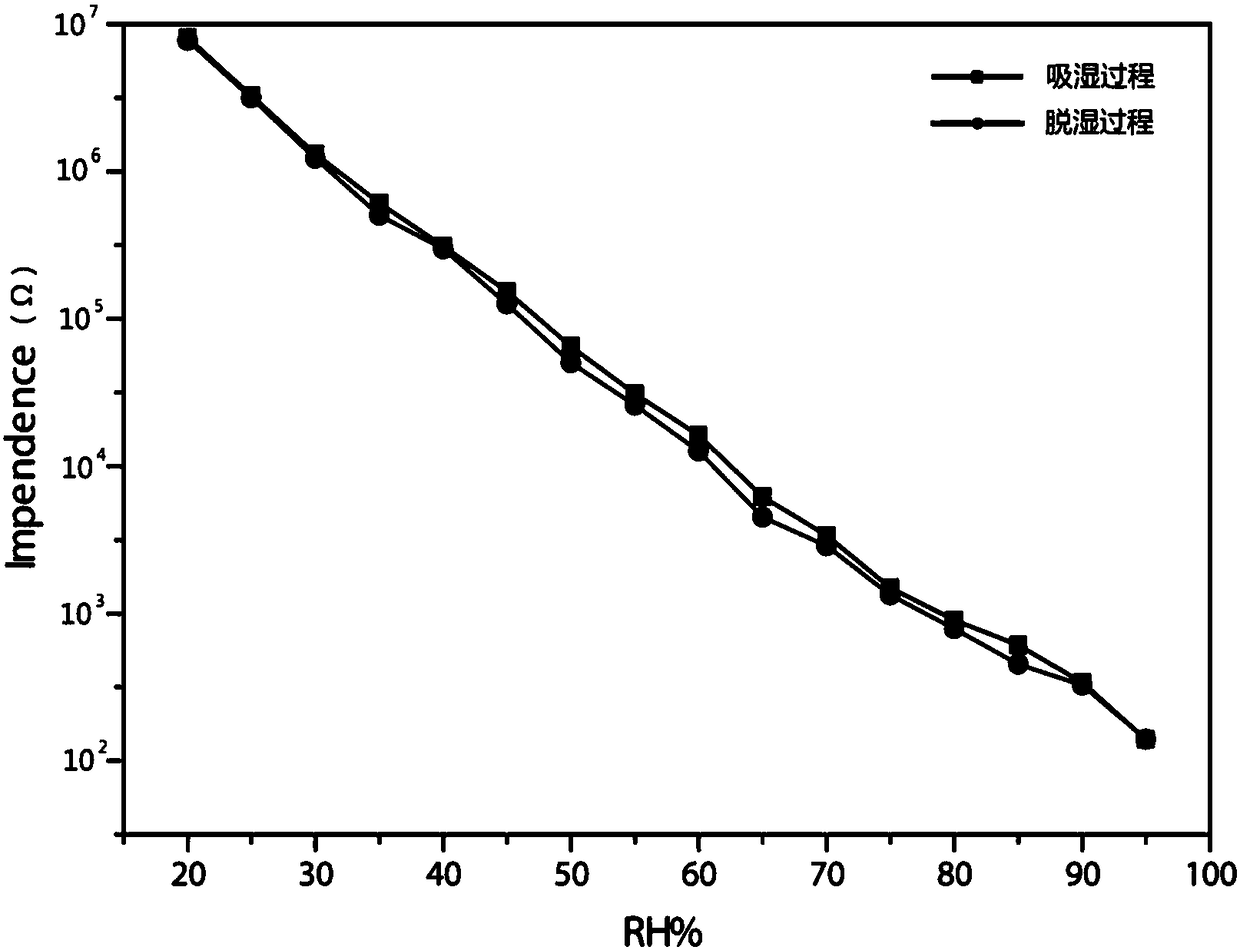

Embodiment 1

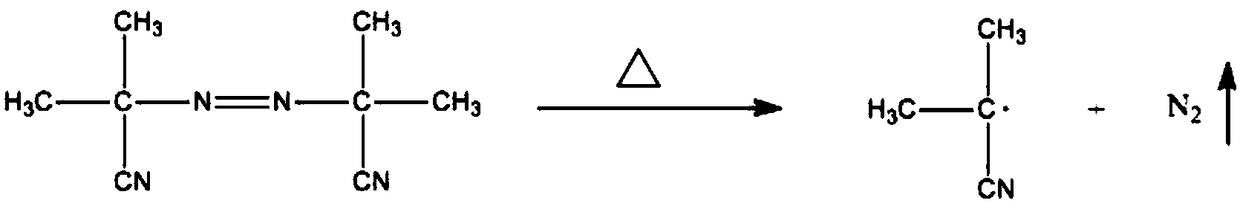

[0037] Take 20 parts of acryloyloxyethyltrimethylammonium chloride, 10 parts of acrylamide, 10 parts of methyl methacrylate, 2 parts of lithium acrylate, and 0.5 parts of initiator AIBN, and place it in a Add methanol to the four-necked flask of the condenser tube and the nitrogen protection device to completely dissolve the reactants, and then react at a constant temperature of 65-85° C. for 4 hours. After the reaction is finished, the obtained product is washed with ether, and then vacuum-dried at room temperature to obtain a resistive polymer moisture-sensitive material.

Embodiment 2

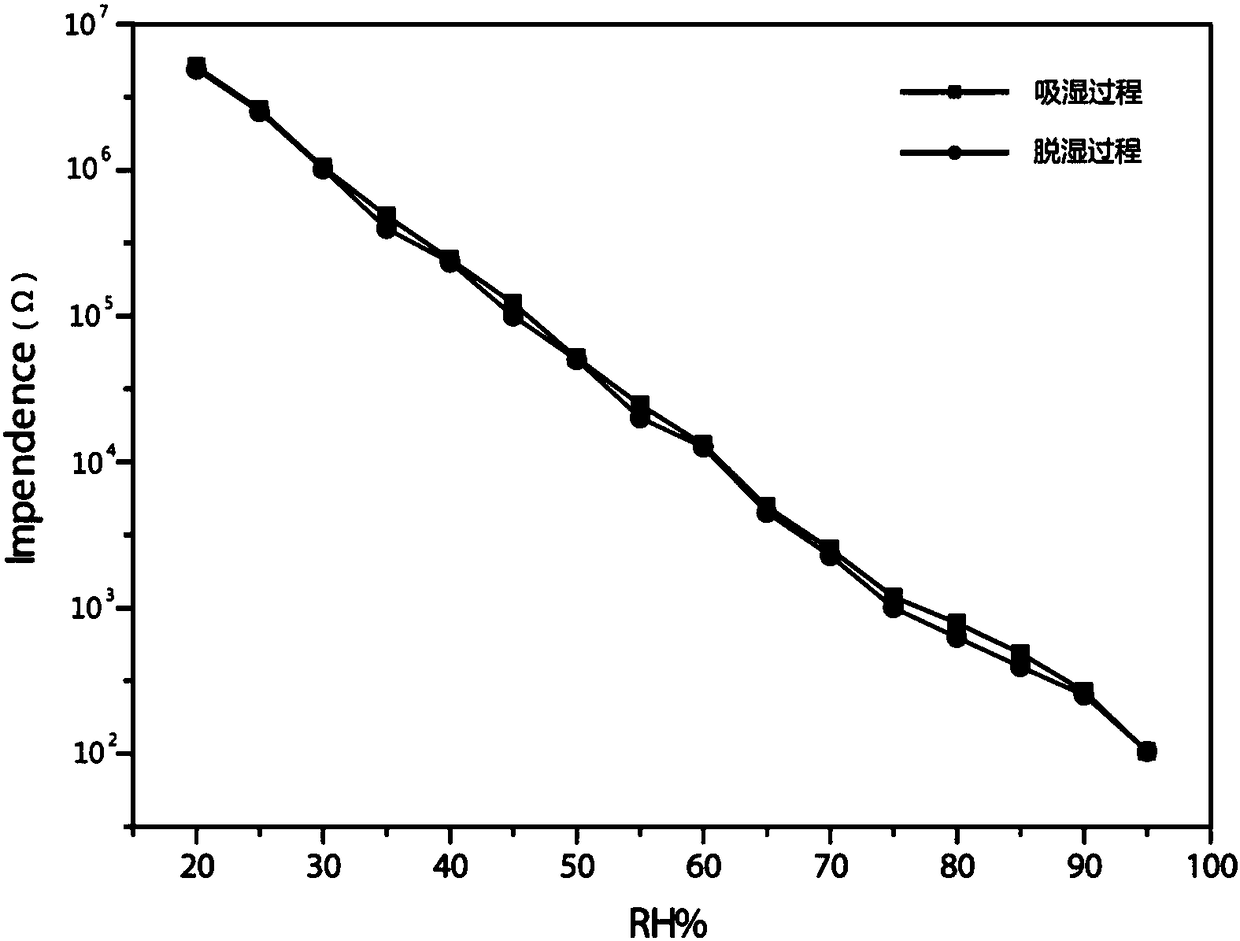

[0039] Take 20 parts of methacryloyloxyethyltrimethylammonium chloride, 40 parts of diethylaminoethyl methacrylate, 10 parts of styrene, 2 parts of sodium styrene sulfonate, 1 part of initiator AIBN, and place in a Methanol was added to a four-necked flask with a thermometer, a stirrer, a reflux condenser and a nitrogen protection device to completely dissolve the reactant, and then reacted at a constant temperature of 65-85° C. for 6 hours. After the reaction, the obtained product was washed with ether and dried in vacuum at room temperature to obtain a resistive polymer moisture-sensitive material.

Embodiment 3

[0041] Take 20 parts of methacryloylpropyltrimethylammonium chloride, 20 parts of dimethyl allylamine, 10 parts of methyl acrylate, 5 parts of sodium styrene sulfonate, and 0.8 parts of initiator AIBN, and put them in the Add methanol to a four-necked flask equipped with a thermometer, a stirrer, a reflux condenser and a nitrogen protection device to completely dissolve the reactants, and then react at a constant temperature of 65-85° C. for 6 hours. After the reaction, the obtained product was washed with ether and dried in vacuum at room temperature to obtain a resistive polymer moisture-sensitive material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com