A capacitive silk protein humidity sensor and preparation method thereof

A humidity sensor and silk protein technology, applied in the direction of material capacitance, etc., can solve the problems of process-limited device integration, low sensitivity, complex circuit, etc., and achieve good humidity response effect, high material utilization rate, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

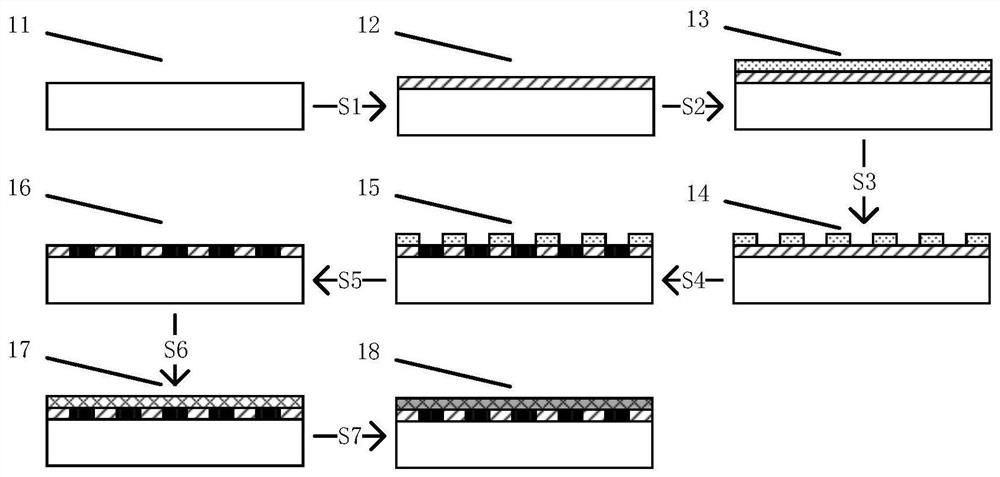

[0028] refer to figure 1 , the preparation method of the capacitive silk protein humidity sensor of the present invention comprises the following steps:

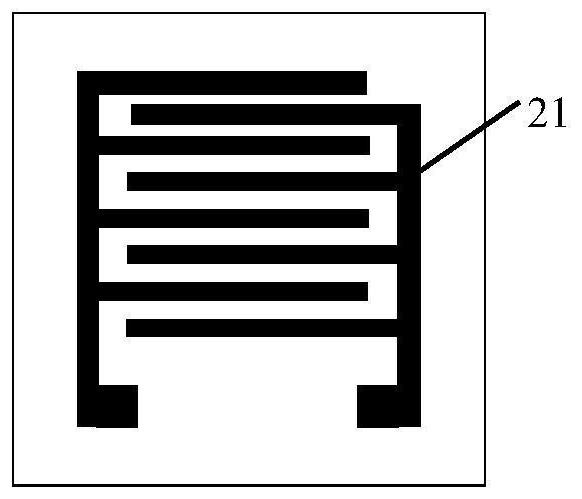

[0029] 1) On the substrate 11, the silver nanowire film 12 and the photoresist film 13 are sequentially scraped and coated on the substrate 11, and then a mask pattern covering the interdigitated electrode area is prepared by a photolithography process to obtain a patterned substrate 11;

[0030] 2) Treating the patterned substrate 11 obtained in step 1) with plasma oxygen to oxidize and insulate the non-electrode region, and then remove the glue to obtain a conductive interdigitated electrode region and an insulating non-electrode region;

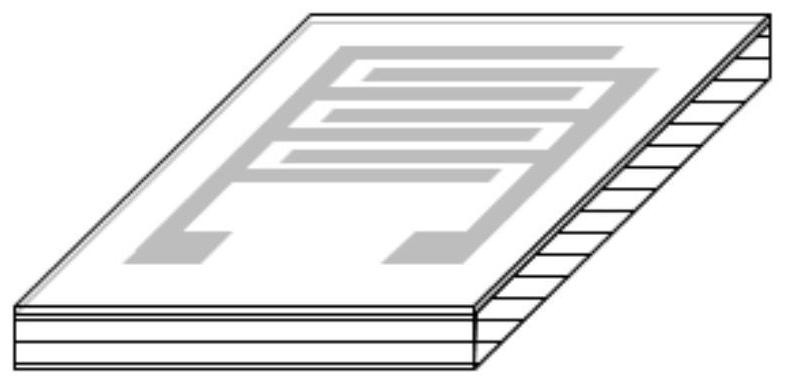

[0031] 3) Scrape the silk protein solution on the conductive interdigitated electrode area and the insulating non-electrode area by scraper coating, air-dry to obtain the silk protein moisture-sensitive film 17, and then place it in an anhydrous ethanol solution to treat the silk protei...

Embodiment 1

[0034] The preparation method of the capacitive silk protein humidity sensor of the present invention comprises the following steps:

[0035] 1) Select flexible substrates, such as dielectric polymers such as polyethylene terephthalate (PET), polyimide (PI) or polyvinylidene fluoride (PVDF), or inorganic substrates such as glass and silicon wafers. For the dielectric material, PET plastic with a thickness of 300 μm is used in this embodiment, and the substrate is ultrasonically cleaned with ethanol and deionized water for 10 minutes, and then dried with an infrared lamp to obtain the substrate 11;

[0036] 2) Scrape-coat the silver nanowire film 12 on the substrate 11 using a doctor blade coater, the distance between the scraper and the substrate 11 is 200 μm, and the scraping speed is 15 mm / min, and the silver nanowire solution used is a dispersion system with deionized water, And the concentration is 10mg / ml, the diameter of silver nanowires is about 100nm, and the length is...

Embodiment 2

[0044] The preparation method of the capacitive silk protein humidity sensor of the present invention comprises the following steps:

[0045] 1) A polyethylene terephthalate film with a size of 10cm×10cm was ultrasonically cleaned with ethanol and deionized water for 10 minutes, and then dried with an infrared lamp to obtain the substrate 11;

[0046] 2) Use a knife coater to evenly coat a layer of silver nanowire thin film 12 on the substrate 11. Specifically, 10 wt % silver nanowire dispersion liquid with a diameter of 50 nm is dropped on the scraper. 15 mm / s, and the height of the scraper is 200 μm, so that the silver nanowire dispersion is evenly coated on the substrate 11. After the scraping is completed, the sample is placed on a heating table at 120° C. for half an hour for heating and curing, and then cooled to room temperature to obtain silver. nanowire film 12;

[0047] 3) Use a scraper coater to uniformly coat a layer of photoresist on the substrate 11 obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com