Automatic aerating boiler for improving combustion efficiency of organic compounds

A technology of organic compounds and combustion efficiency, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of inability to perform multi-directional turning, boilers do not have turning and incineration, boilers can only perform directional turning, etc., to achieve Avoid the effect of incomplete incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

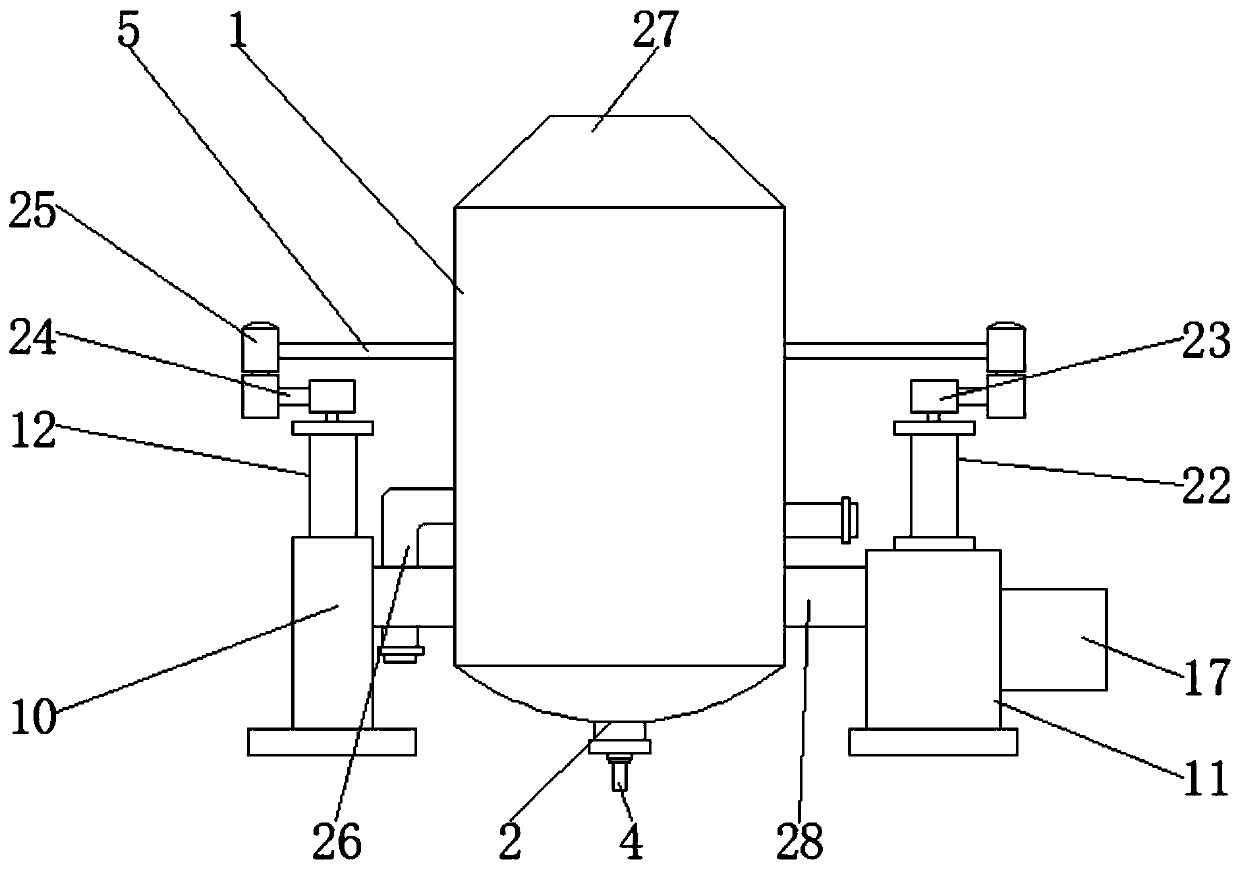

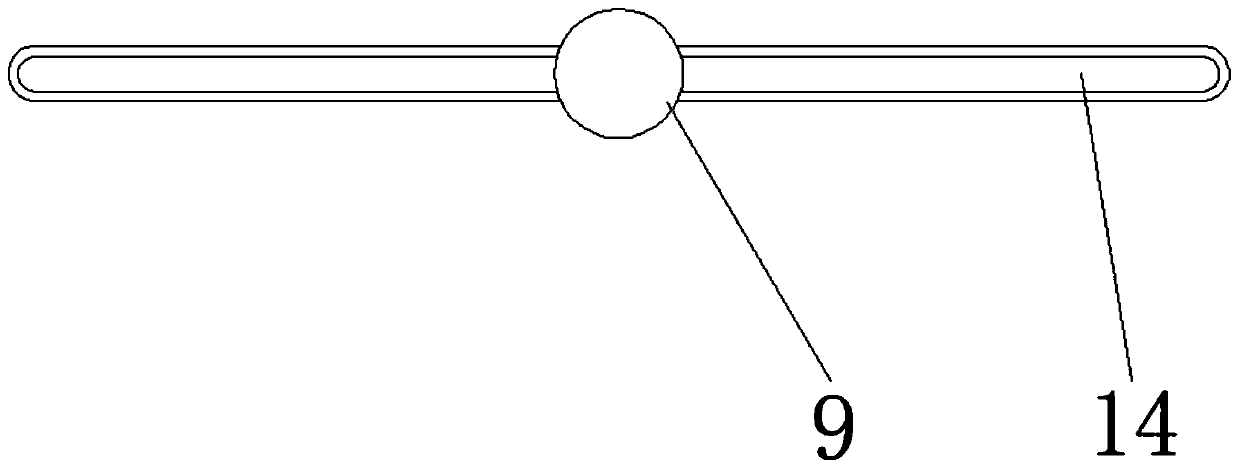

[0024] see Figure 1-4 As shown, the present invention provides a technical solution: an automatic oxygen-increasing boiler that improves the combustion efficiency of organic compounds, including a furnace body 1, a burner 2 is fixedly installed at the bottom of the furnace body 1, and the top of the burner 2 runs through and extends to The inside of the furnace body 1, and the top of the burner 2 is fixedly installed with the ignition device 3, the bottom of the burner 2 is fixedly connected with the fuel pipe 4, and the two sides of the inside of the furnace body 1 are respectively connected with the fixed plate 6 through the connecting rod 5. One end of the two connecting rods 5 runs through and extends to the outside of the furnace body 1, and the other ends of the two connecting rods 5 are respectively fixedly connected to both sides of the fixed plate 6, and the top of the fixed plate 6 is fixedly equipped with a turning motor 7, The outer side of the material turning mo...

Embodiment 2

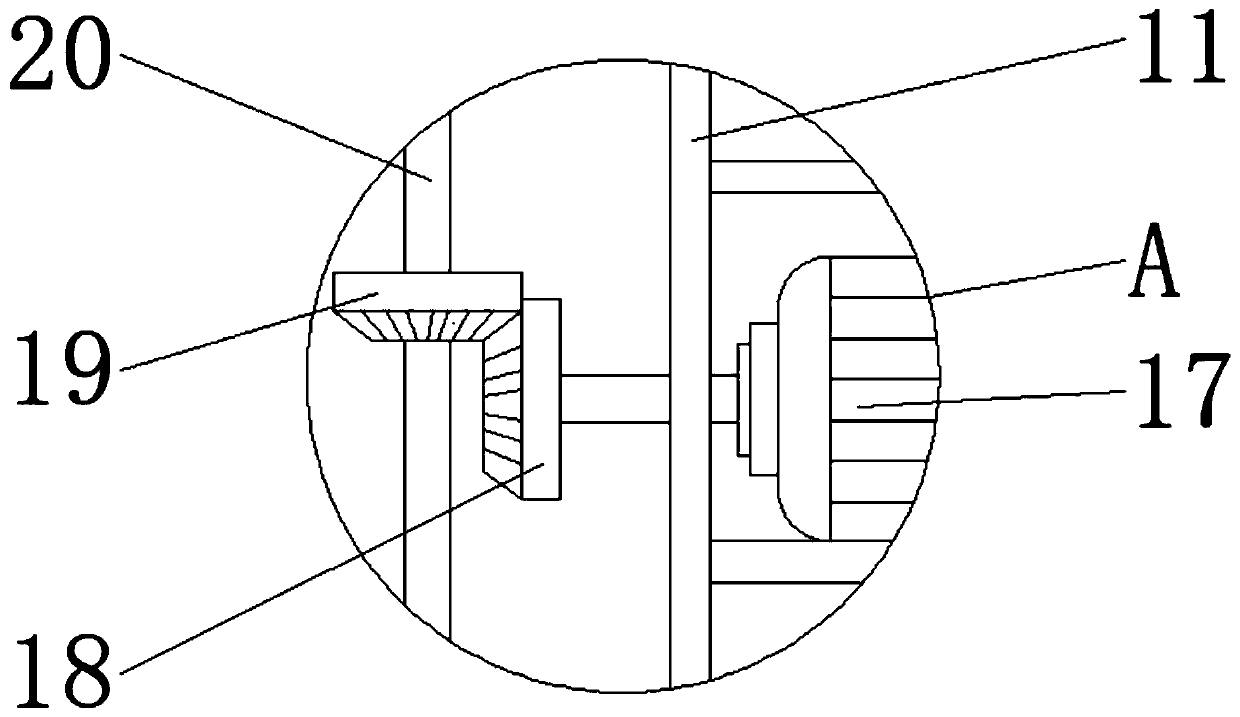

[0028] On the basis of Embodiment 1, the left and right sides of the furnace body 1 are provided with a left support 10 and an outer plate 11 of the device, and both sides of the furnace body 1 are fixedly connected with the left support 10 and the outer plate 11 of the device. Main bar 28, the top of left support 10 is fixedly installed with connecting outer plate 12, the left side and top of device outer plate 11 are fixedly installed with reciprocating motor 17 and protection outer plate 22 respectively, the left side output end of reciprocating motor 17 runs through and Extending to the inside of the outer plate 11 of the device, and fixedly connected with a vertical bevel gear 18, the outer edge of the vertical bevel gear 18 is meshed with a horizontal bevel gear 19, and the inner wall of the horizontal bevel gear 19 is fixedly connected with a rotating rod 20, and the rotating rod The bottom end of 20 is movably connected with the bottom of the inner wall of the device ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap