A group intelligent coal mining machine cutting mode recognition system based on integrated learning

A pattern recognition and integrated learning technology, applied in the field of signal processing, can solve problems such as the impact of recognition rate, difficult maintenance of the system, and increase in the cost of detection equipment, so as to solve the problem of accuracy and confidence decline, ensure safe operation, and achieve good optimization results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below according to the accompanying drawings.

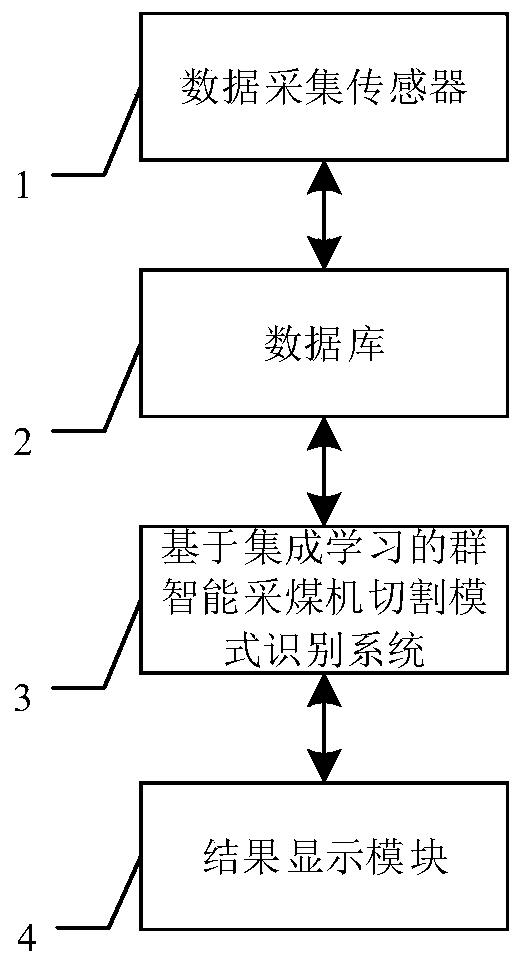

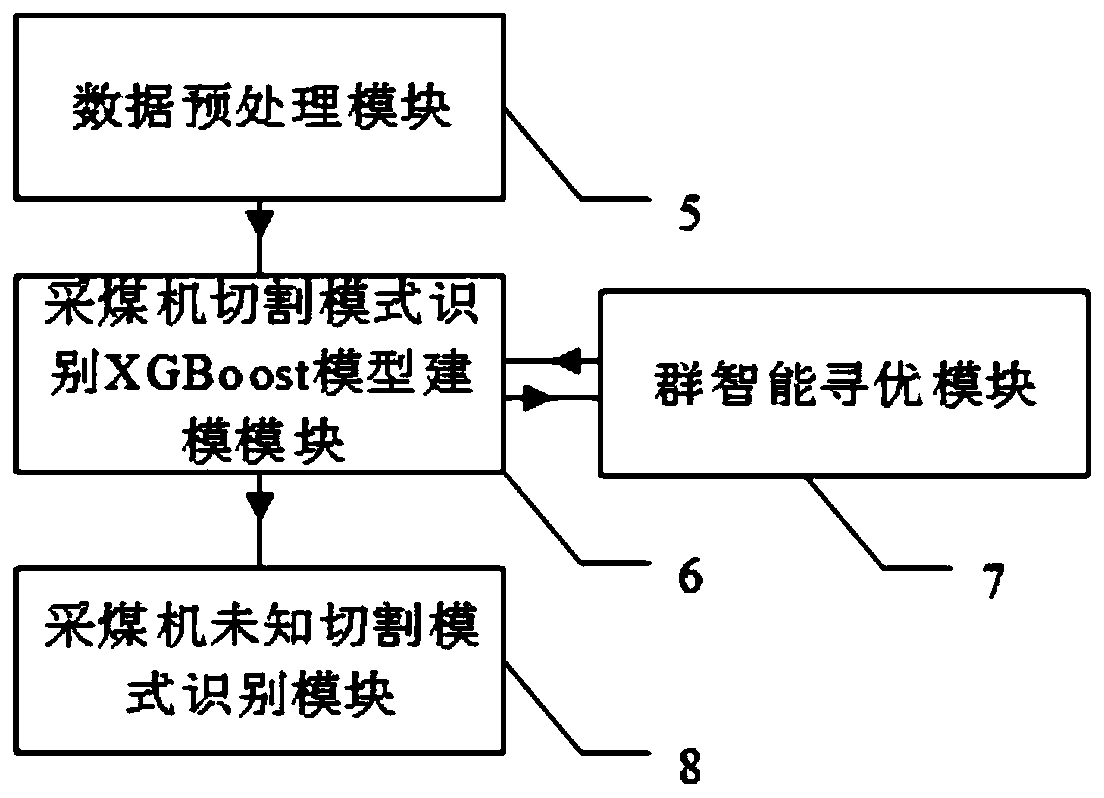

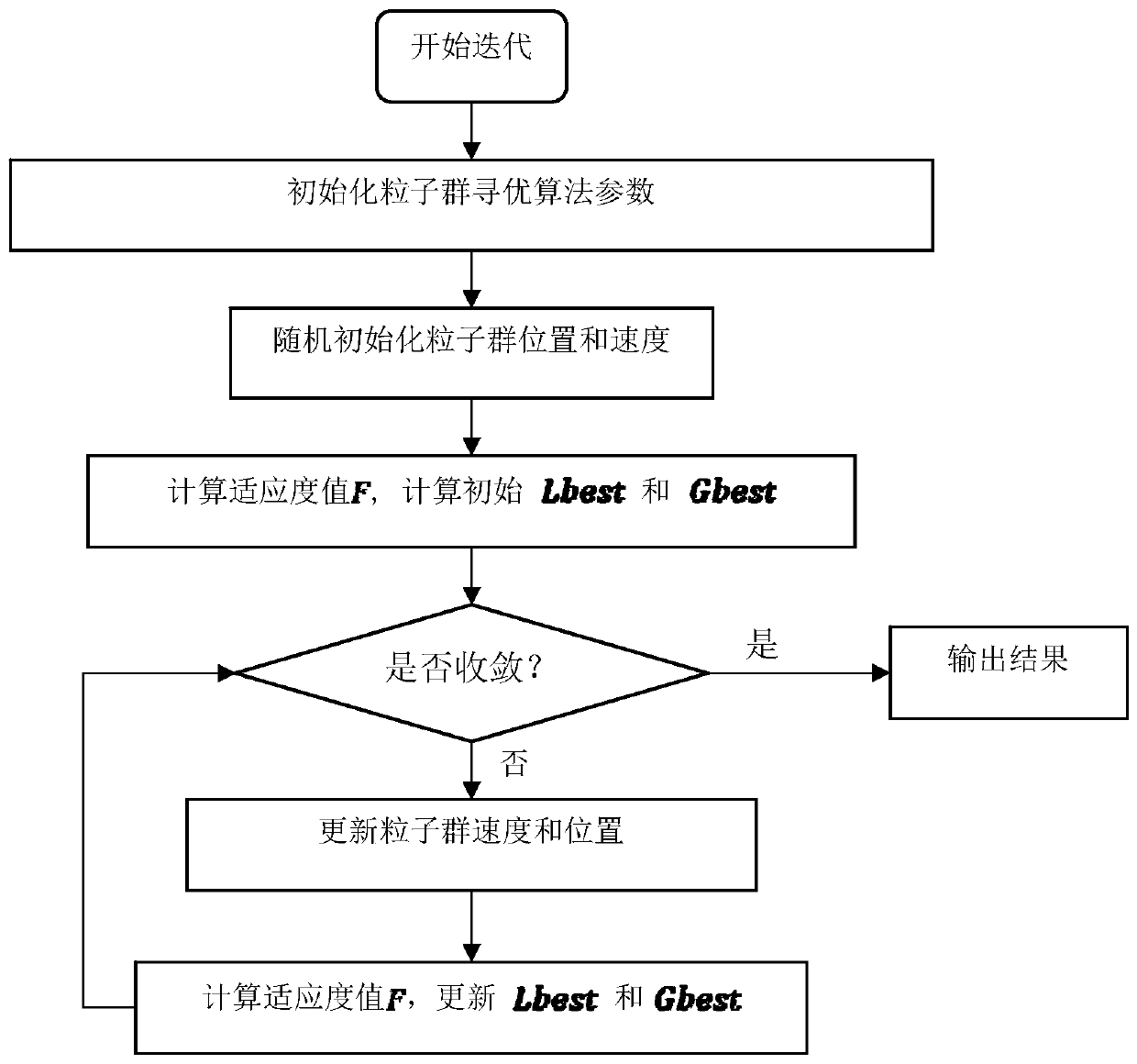

[0045]refer to figure 1 , figure 2 , image 3 As shown, the swarm intelligent shearer cutting pattern recognition system based on integrated learning includes data preprocessing module 5, shearer cutting pattern recognition limit gradient boosting (eXtreme Gradient Boosting, XGBoost) model modeling module 6, swarm intelligence optimization Module 7 and coal mining machine unknown cutting pattern recognition module 8. The data acquisition sensor 1, the database 2, the group intelligent shearer cutting pattern recognition system 3 based on integrated learning, and the result display module 4 are connected in sequence, and the data acquisition sensor 1 works on the speed, current, voltage, etc. when the shearer is cutting. Parameters are collected, and part of the data can be manually marked as tags, and the data is stored in the database 2. The historical shearer cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com