Easy-to-tear film combined cap for soft infusion bag

A technology of infusion soft bag and easy-tear film, applied in the field of medical packaging, can solve the problems of many puncture chips, difficult puncture, easy pollution, etc., and achieves the solution of many puncture chips, reduces cross and secondary pollution, and has good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a further detailed description through specific implementations:

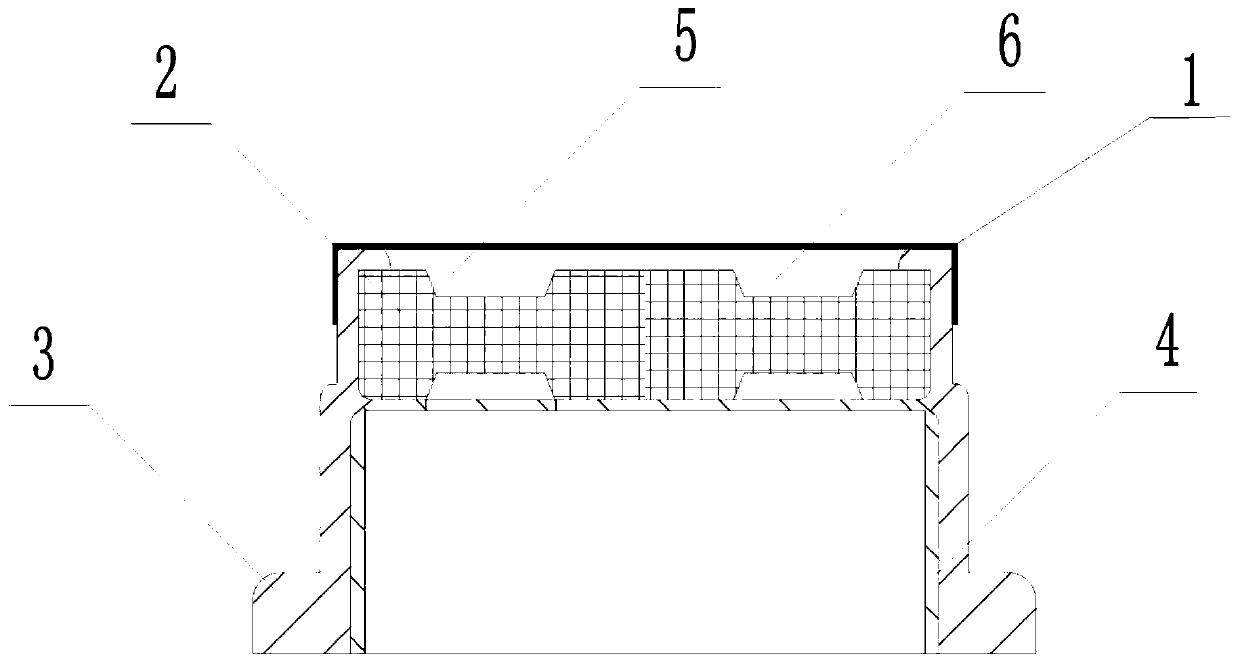

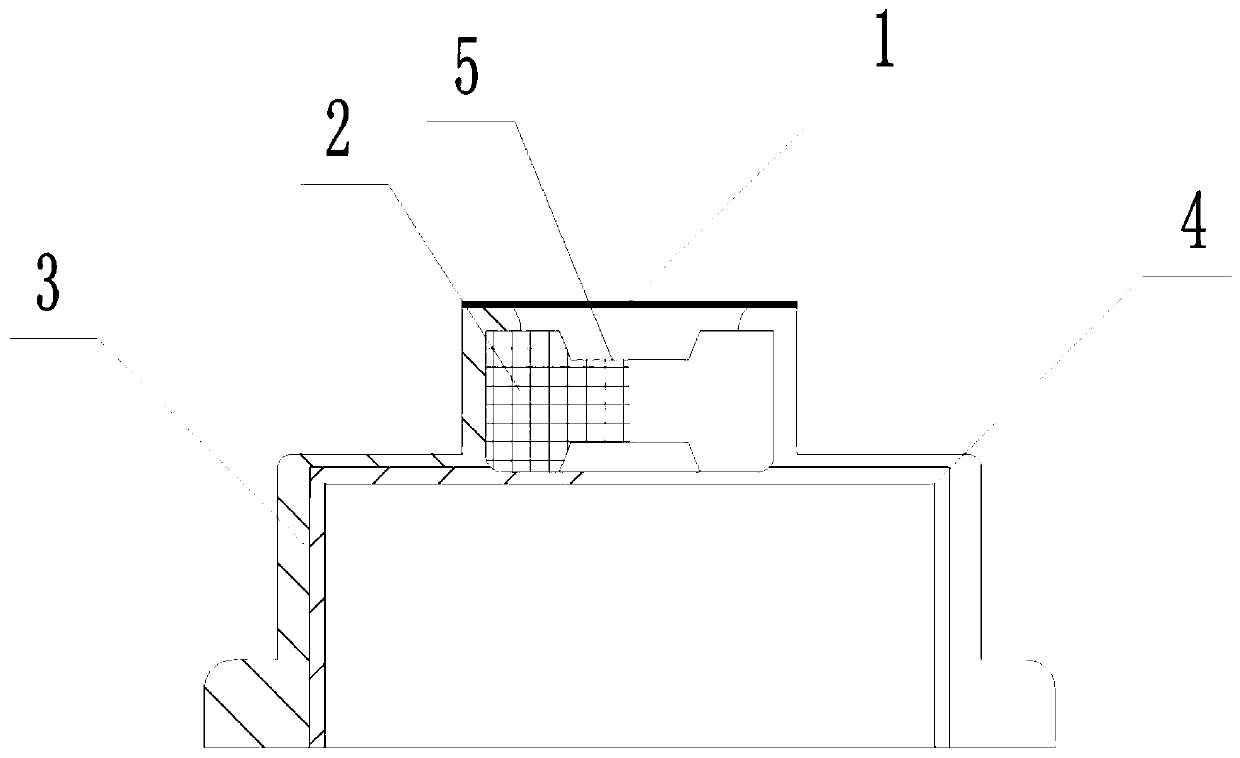

[0016] The reference signs in the drawings of the specification include: film 1, gasket 2, outer cover 3, inner cover 4, medicated hole 5, and infusion hole 6.

[0017] The embodiment is basically as attached Figure 1-2 Shown:

[0018] An easy-tear film combination cover for infusion soft bags, comprising an outer cover 3 and an inner cover 4. The inner cover 4 is nested on the inner wall of the outer cover 3, and both the outer cover 3 and the inner cover 4 are made of polypropylene. The cover 3 and the inner cover 4 are ultrasonically welded. The top of the outer cover 3 is provided with a medicating hole 5 and an infusion hole 6 passing through the outer cover 3 and the inner cover 4, and the height of the openings of the medicating hole 5 and the infusion hole 6 is lower than the top of the outer cover 3 The height of the upper surface, between the outer cover 3 and the inner cover 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com