Engine oil cooling equipment and manufacturing method thereof

A technology of engine oil cooling and manufacturing method, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of complex injection molding and demoulding of the filter cover, and increase the difficulty of design, so as to achieve simple mechanism and reduce use requirements , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

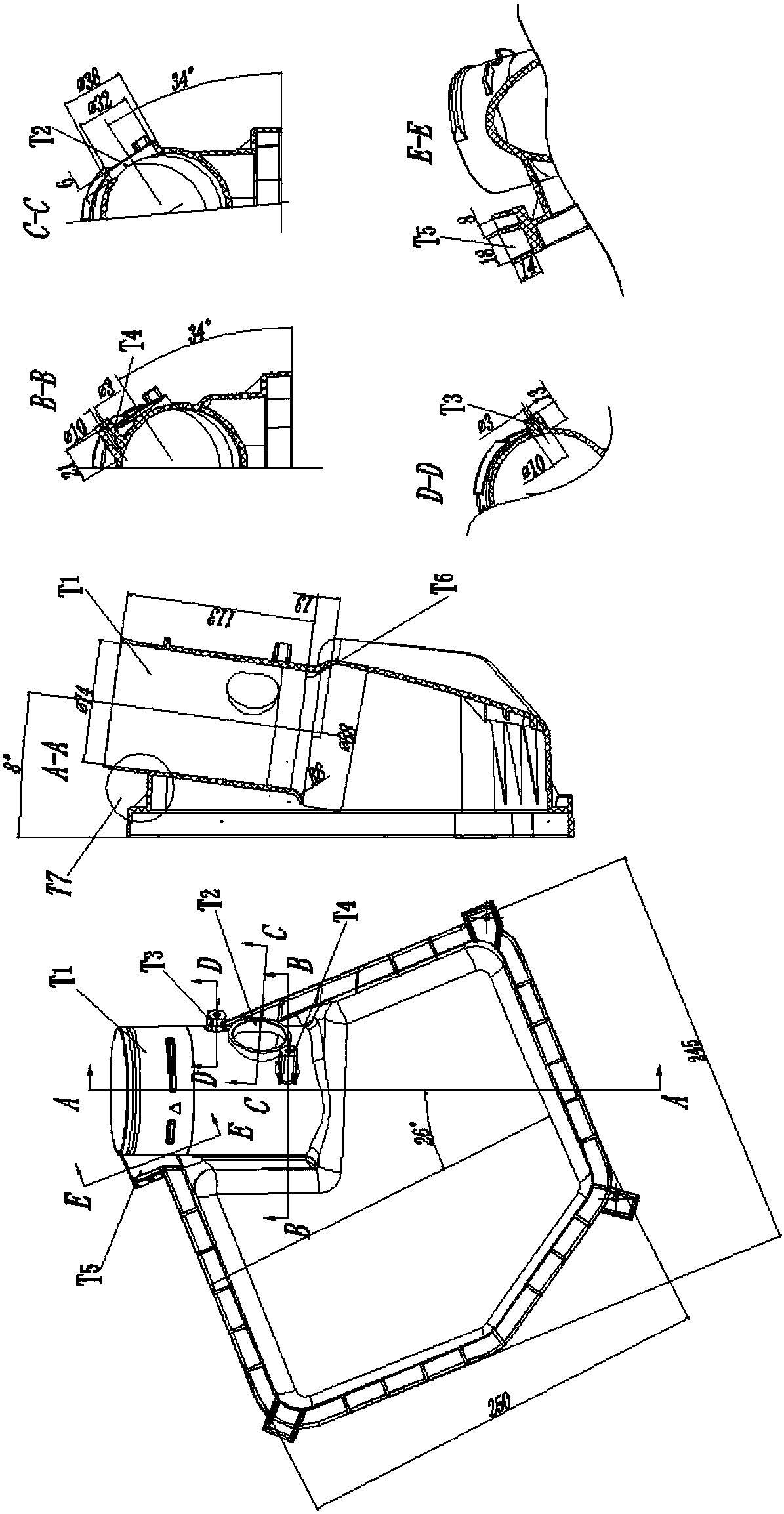

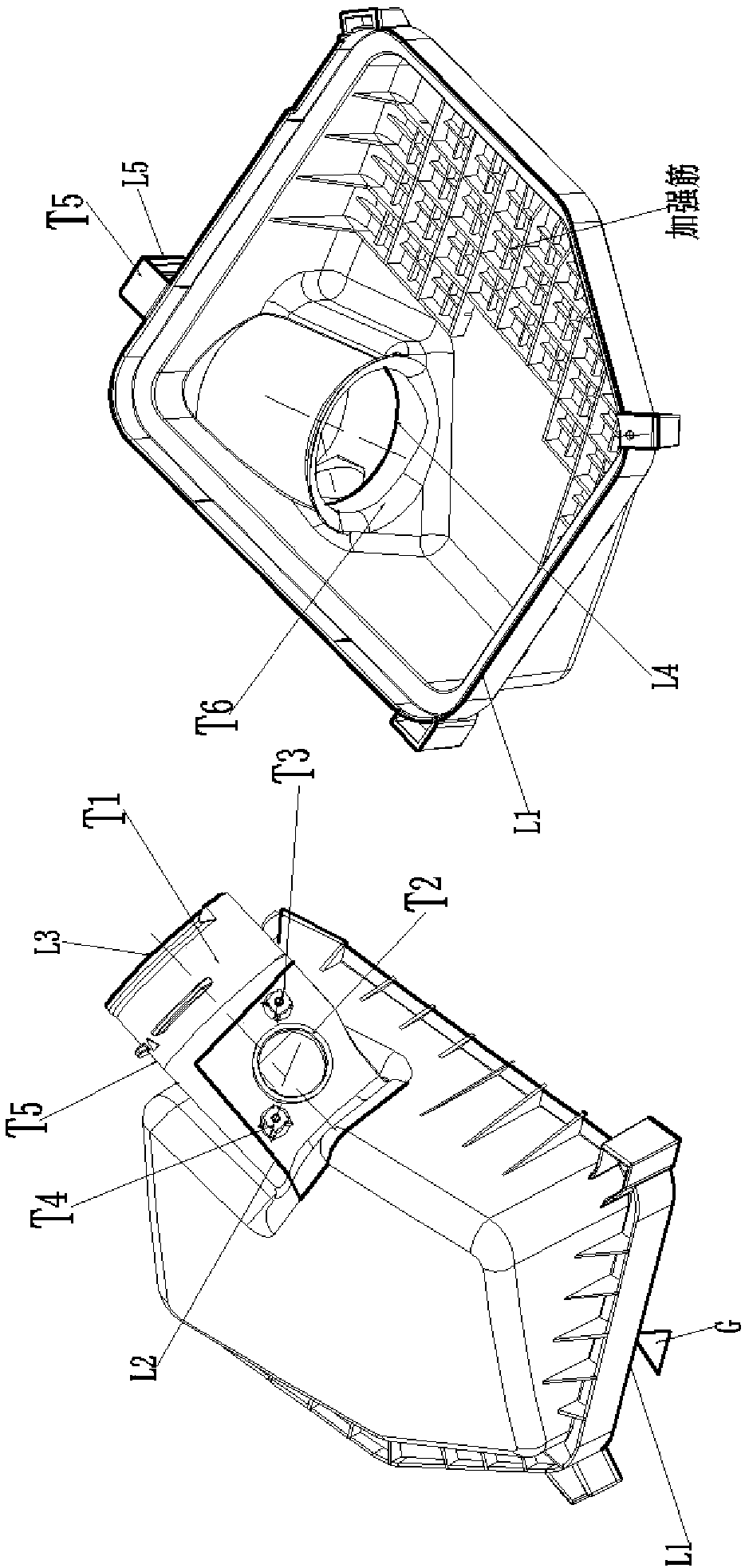

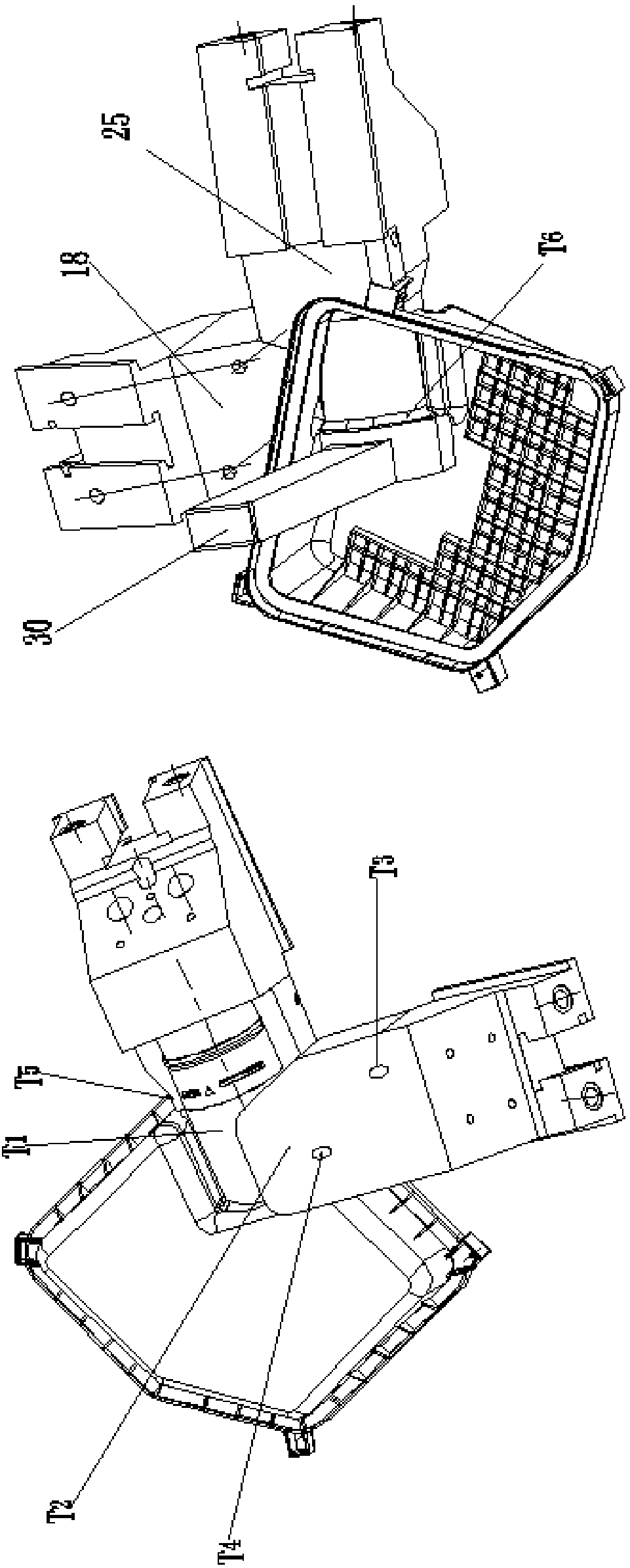

[0019] Figure 1-4 Shown is the relevant explanatory diagram of the present invention; a certain oil cooling equipment filter cover product such as figure 1 As shown, the material is modified plastic ABS+20%PC+G, the shrinkage rate is 0.6%, (PC / ABS German Bayer FR2010 injection grade is easy to flow and flame retardant); the average wall thickness of the product is 3mm; the structure of the product is composed of two parts, The main body of the filter box cover and the 7 features on the box cover T1~T7T1 is the intake manifold, T2 is the sub-pipe interface on the intake manifold; T3 and T4 are the fastening screw columns of the sub-pipe joints; T5 is the main body of the box cover. The feature of inserting holes on one side; T6 is a circular arc transition section extending from the central pipe of the manifold to the center of the box cover; T7 is the undercut area formed between the feature of T1 and the edge of the main body of the box cover; the inner side of the box cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com