Three-dimensional (3D) printing device with cooperative parallel multiple nozzles

A 3D printing and multi-nozzle technology, applied in the field of 3D printing, can solve the problems that FFF 3D printers are difficult to market, hinder the development of FFF 3D printers, and consume too much time, so as to facilitate market applications, improve printing efficiency, reduce The effect of molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

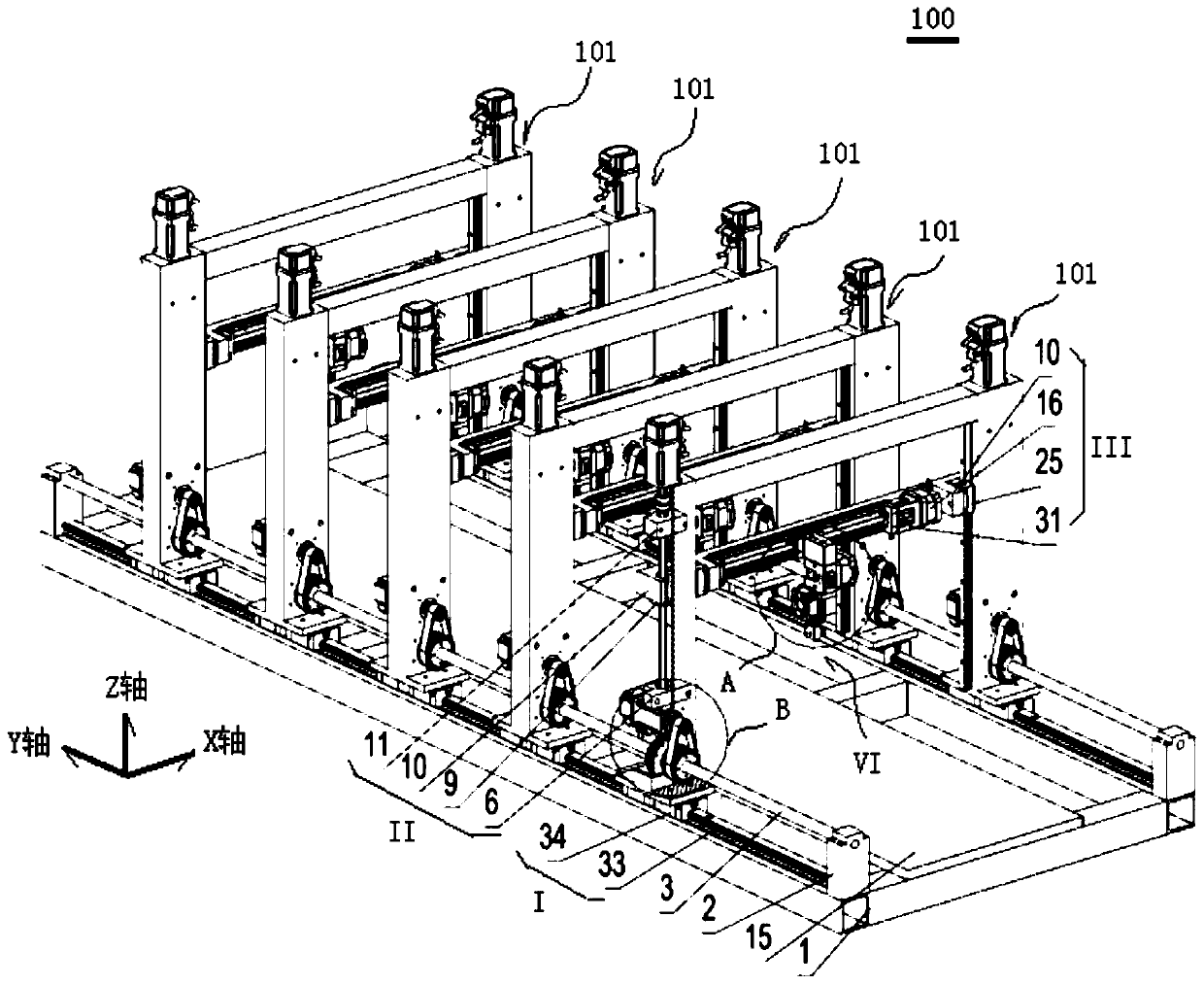

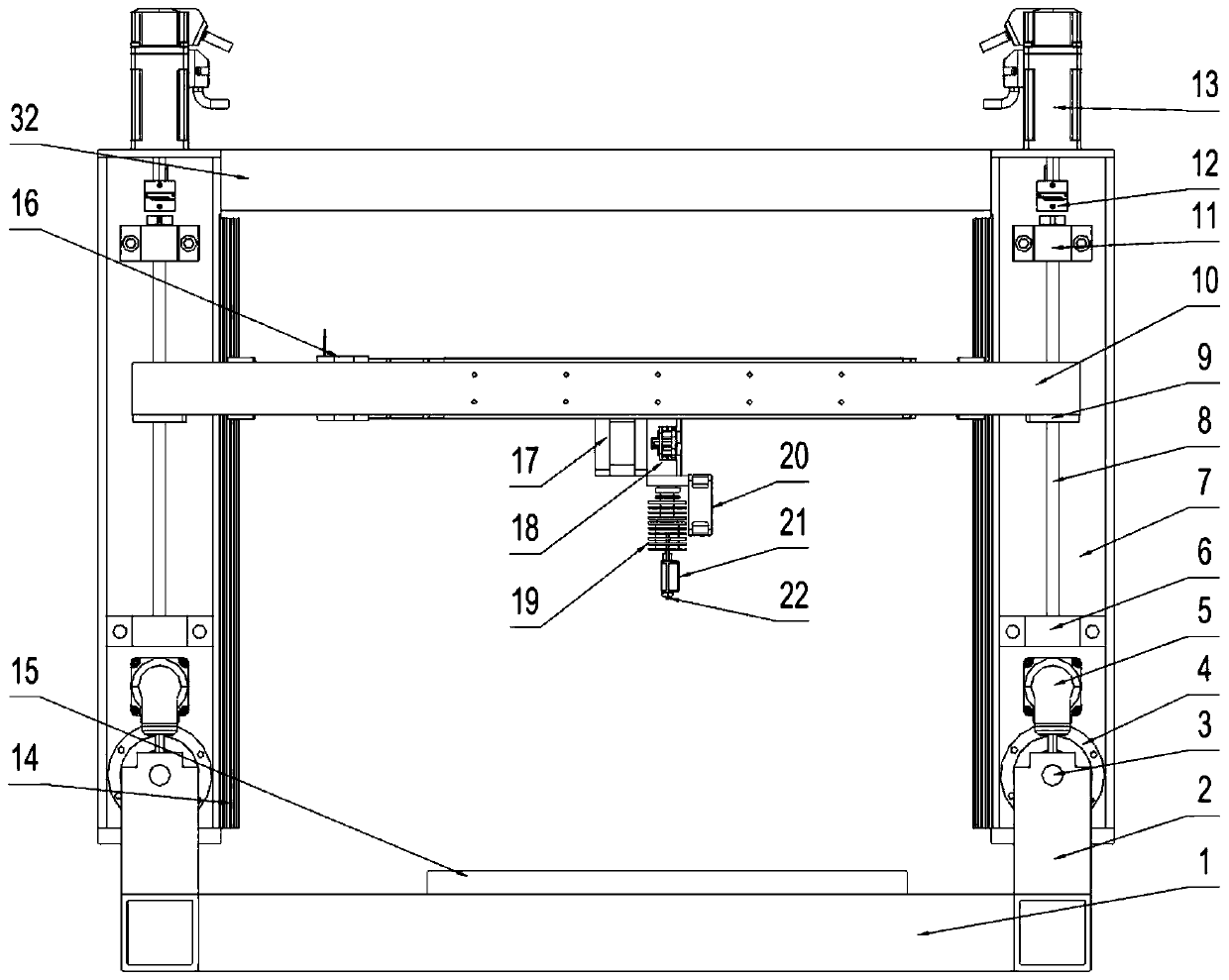

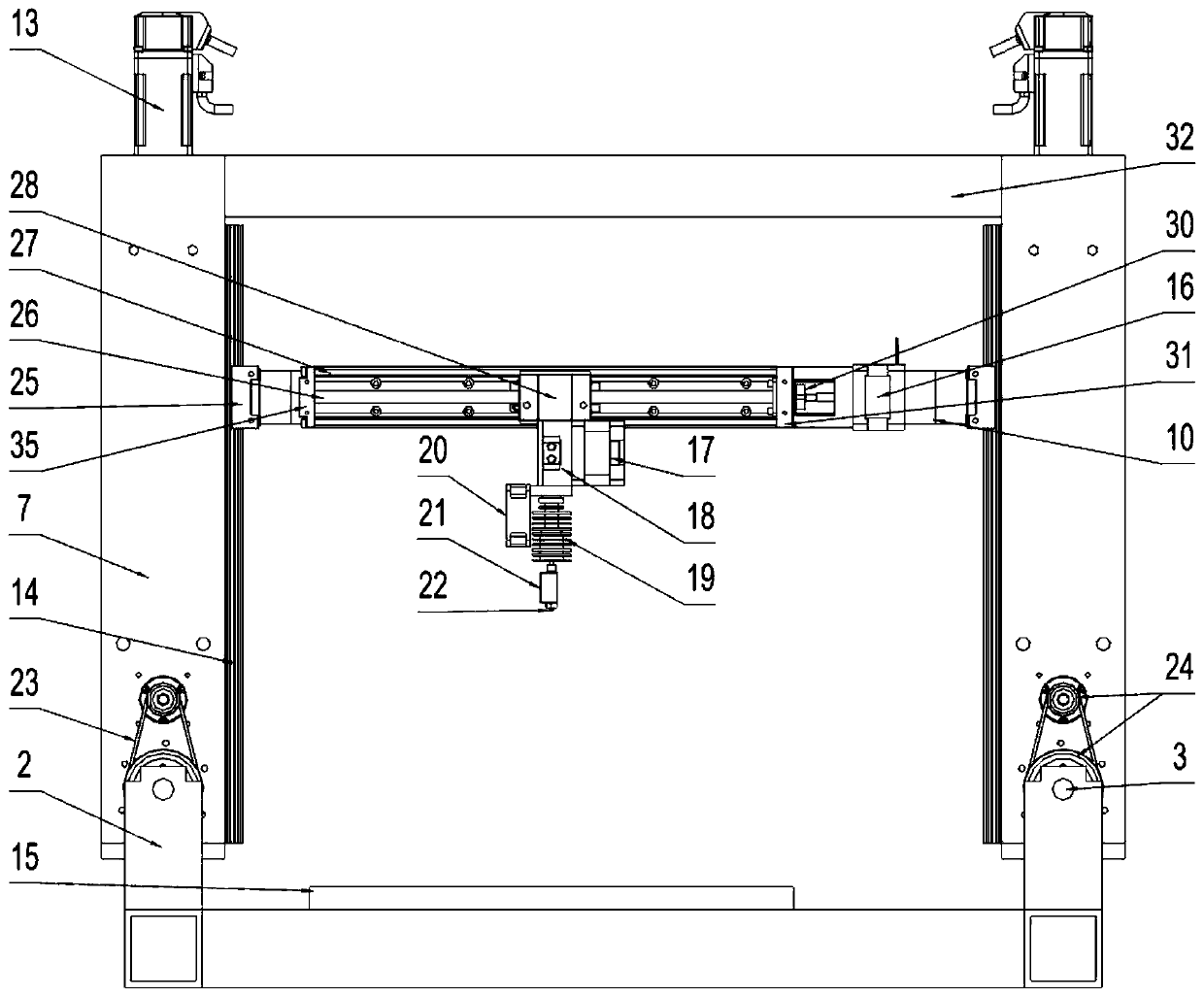

[0062] figure 1 It is a schematic perspective view of a 3D printing device with coordinated parallel multi-nozzles according to an embodiment of the present application. figure 2 yes figure 1 The schematic front view of the 3D printing device with coordinated parallel multi-jet heads shown. image 3 yes figure 2 The schematic structural diagram of the 3D printing device with coordinated parallel multi-nozzles after cutting the X-axis bracket is shown. Figure 4 yes figure 1 Schematic partial enlarged view of A shown. Figure 5 yes figure 1 Schematic partial enlarged view of B shown.

[0063] Such as figure 1 shown, see also Figure 2-Figure 5 , in this embodiment, a 3D printing device 100 with coordinated parallel multi-nozzle heads may generally include: a main body support 1 , a printing platform 15 , a Y-axis screw, and a plurality of 3D printing units 101 . The main body support 1 is arranged at the bottom for supporting other parts in the 3D printing device 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com