Warm-keeping and moisture-permeable synthetic fiber

A synthetic fiber and moisture-permeable technology, applied in the fiber field, can solve the problems of poor moisture absorption, warmth retention and elasticity to be improved, and achieve good moisture absorption, warmth retention and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

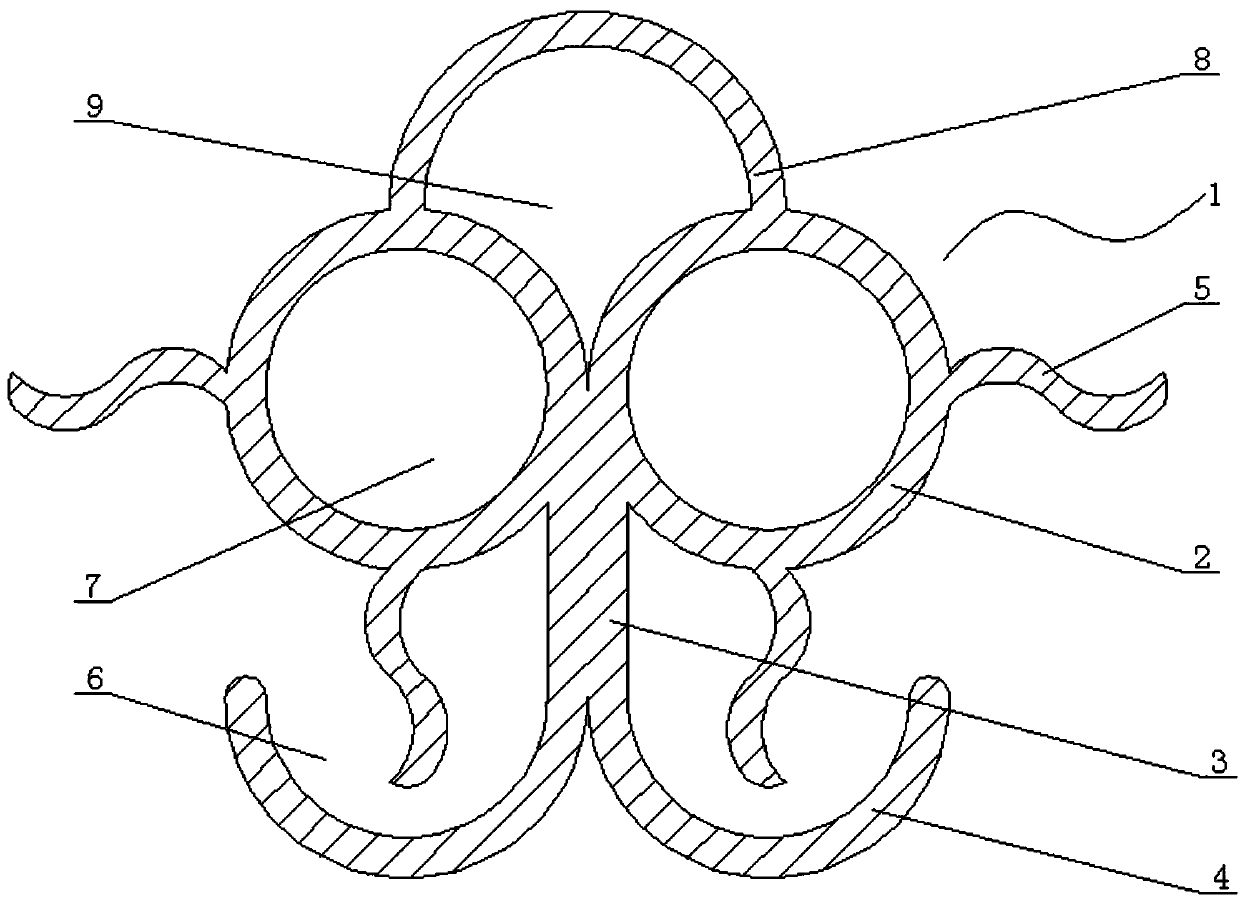

[0009] Such as figure 1 As shown, a warm and moisture-permeable synthetic fiber includes a main body 1, the main body 1 is composed of two symmetrically arranged glyph-shaped fibers, and the glyph-shaped fibers include a ring part 2 and an upright part 3 connected together in sequence and arc-shaped part 4, two upright parts 3 of ɡ-shaped fibers are attached to each other. The upright part 3 is arranged longitudinally. The two ends of the upright part 3 are respectively connected to the inner side of the ring part 2 and one end of the arc-shaped part 4. Good elasticity and fluffiness.

[0010] The ring part 2 is provided with a first cavity 7, and the first cavity 7 contains a large amount of still air, which has good warmth retention and elasticity.

[0011] A wave-shaped extension 5 is provided at ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap