Dust-removing ribbon loom

A ribbon loom and ribbon technology, applied in looms, textiles, textiles, and papermaking, can solve the problems of frizzy ribbon surface, contamination of loom parts, and broken yarns, so as to improve production quality, improve aesthetics, and prevent tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

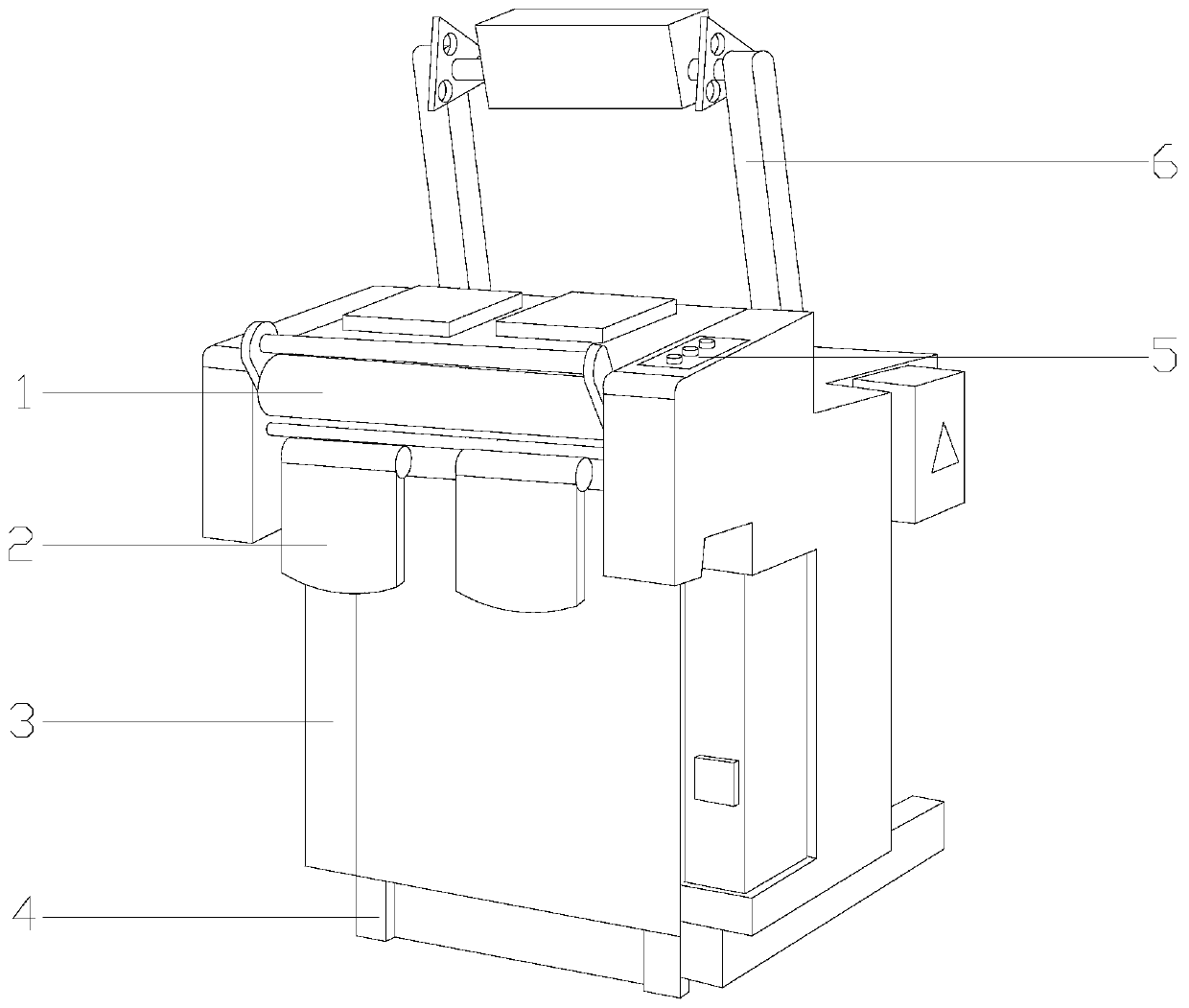

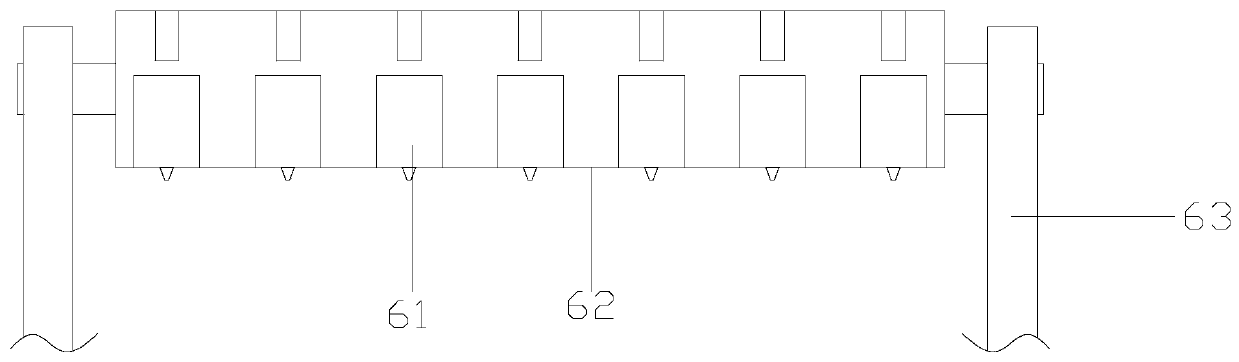

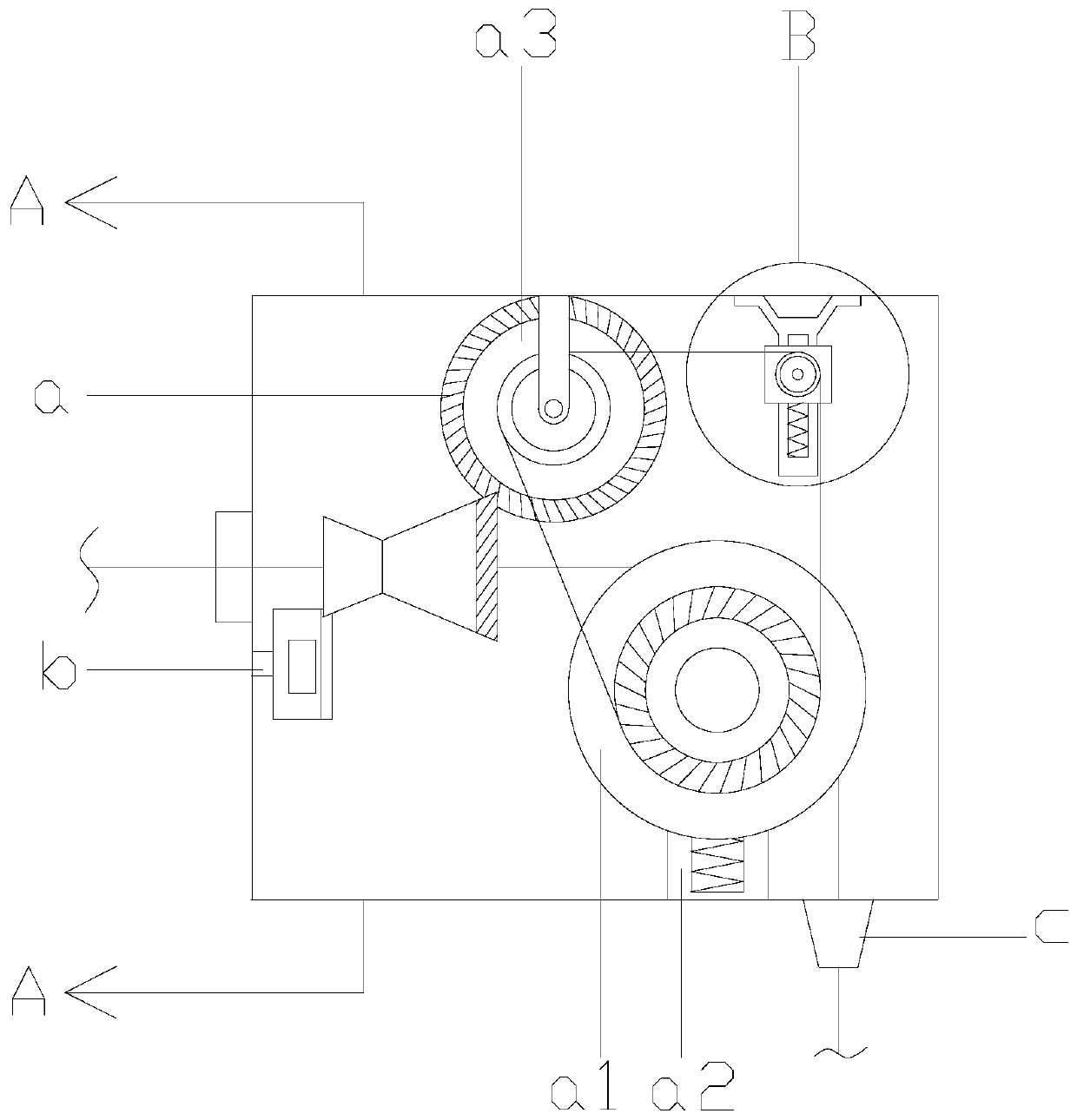

[0027] see Figure 1-Figure 2 , the present invention provides a kind of dust removal loom, its structure comprises ribbon transmission wheel 1, ribbon fixing plate 2, ribbon loom main body 3, support base 4, control panel 5, yarn traction device 6, the bottom of described support base 4 and the ground close together, the main body 3 of the loom is a rectangular structure and the bottom and the upper surface of the support base 4 are screwed together, the ribbon transmission wheel 1 is nested on the upper surface of the main body 3 of the loom, and the ribbon fixing plate 2 There are two and are horizontally installed in front of the ribbon transmission wheel 1, the yarn traction device 6 is interlocked with the ribbon loom main body 3, the control panel 5 is installed on the right end of the upper surface of the ribbon loom main body 3 and the bottom surface is connected to the ribbon loom main body 3 are fixed together by bolts, and the yarn traction device 6 is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com