Indoor wall paint shoveling device

A technology for interior wall paint and wall paint, which is applied in the direction of architecture and building structure, can solve the problems of great construction environment pollution, inconvenient removal depth of paint surface, low construction efficiency, etc., so as to reduce dust flying and facilitate removal work. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

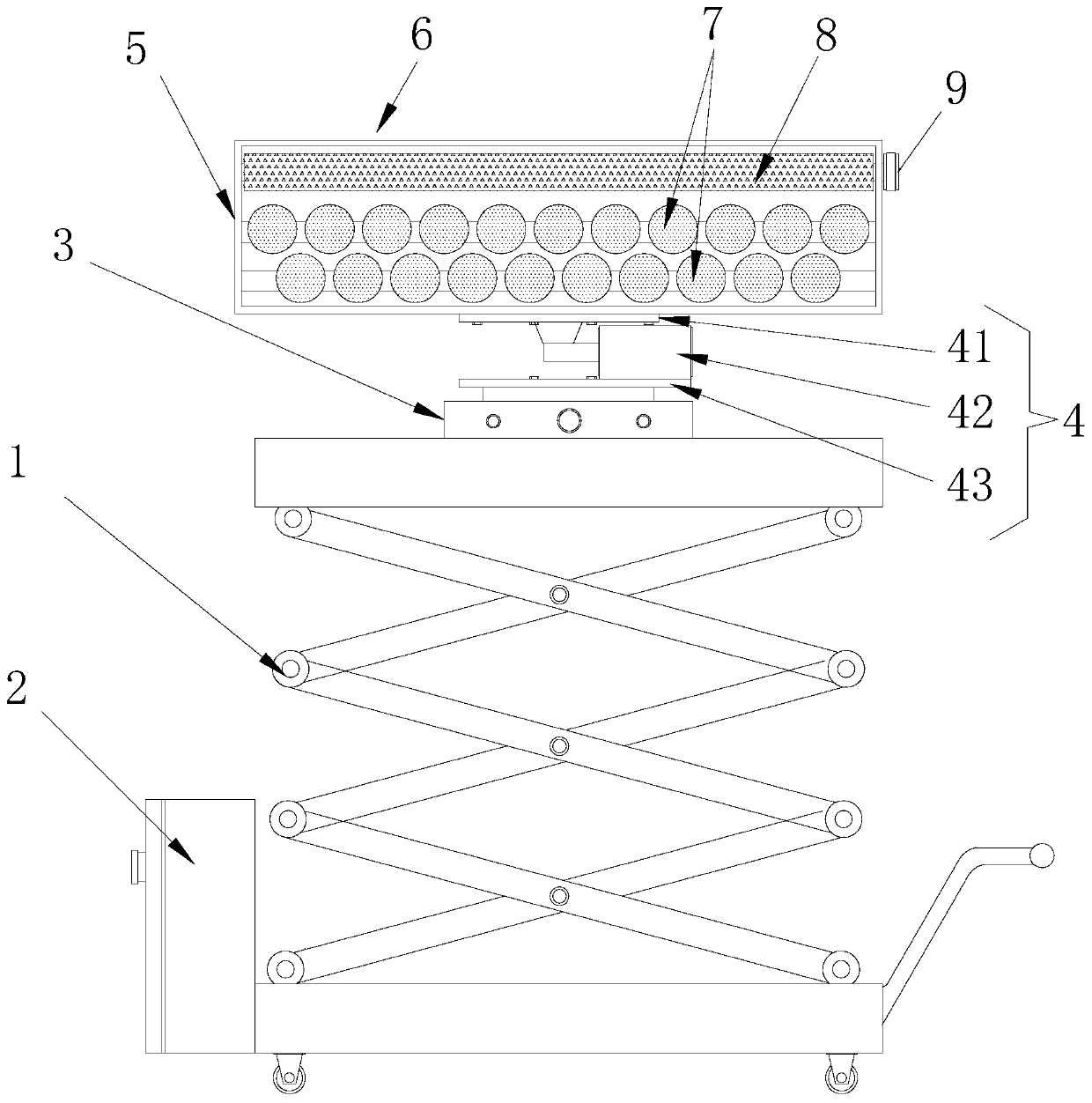

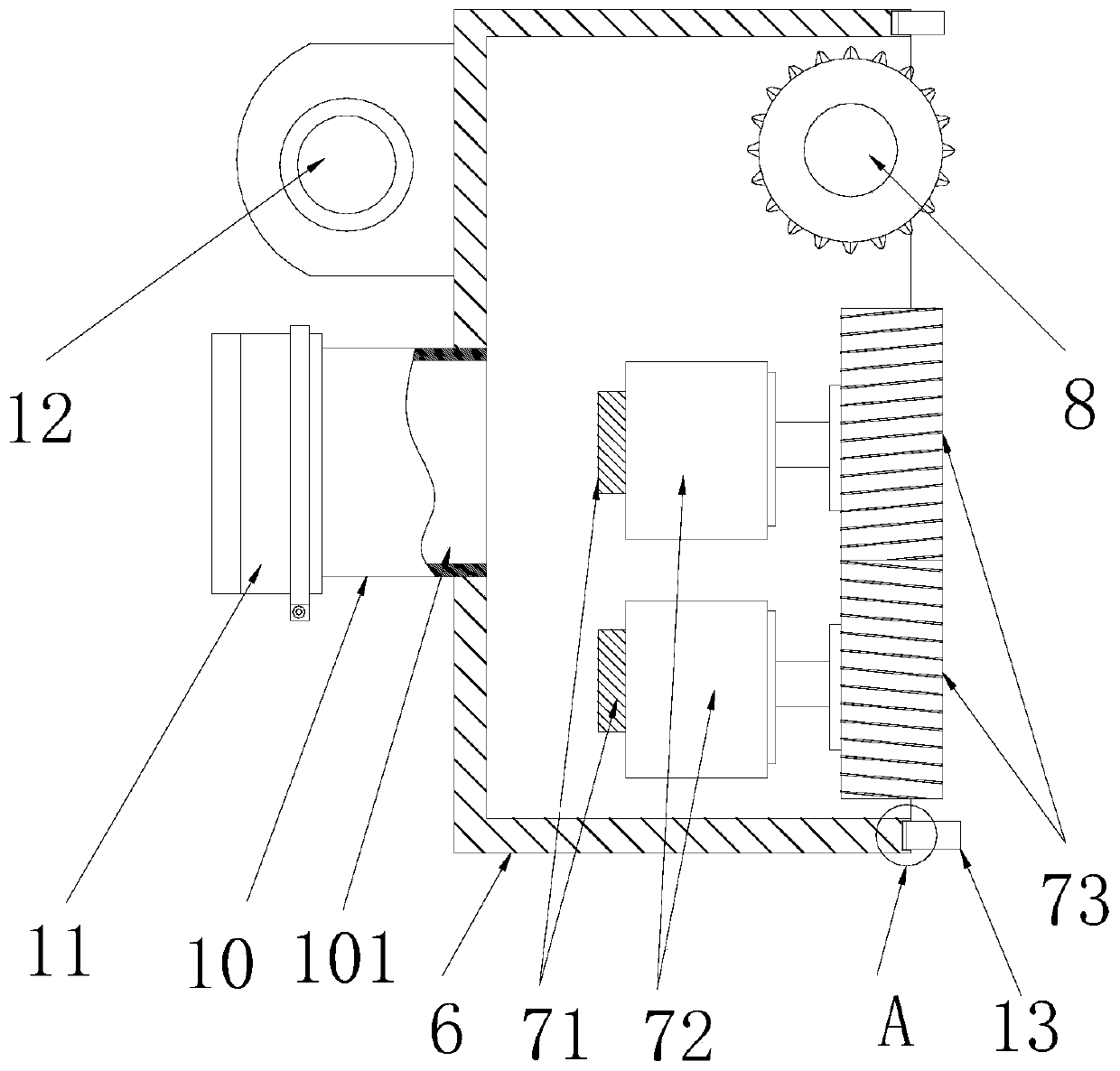

[0033] Such as Figure 1-6 As shown, a kind of indoor wall paint removal device comprises a mobile elevating platform 1, and a horizontally arranged high-precision one-dimensional translation platform 3 arranged on the top of the mobile elevating platform 1, and the movable part of the high-precision one-dimensional translation platform 3 is connected with Rotary support mechanism 4, the rotation of described rotary support mechanism 4 is connected with a wall paint removal mechanism 5, and wall paint removal mechanism 5 rotates on the vertical plane by rotation support mechanism 4, and one side of the mobile lifting platform 1 An electric control box 2 is provided, and the mobile lifting platform 1 is connected with the electric control box 2;

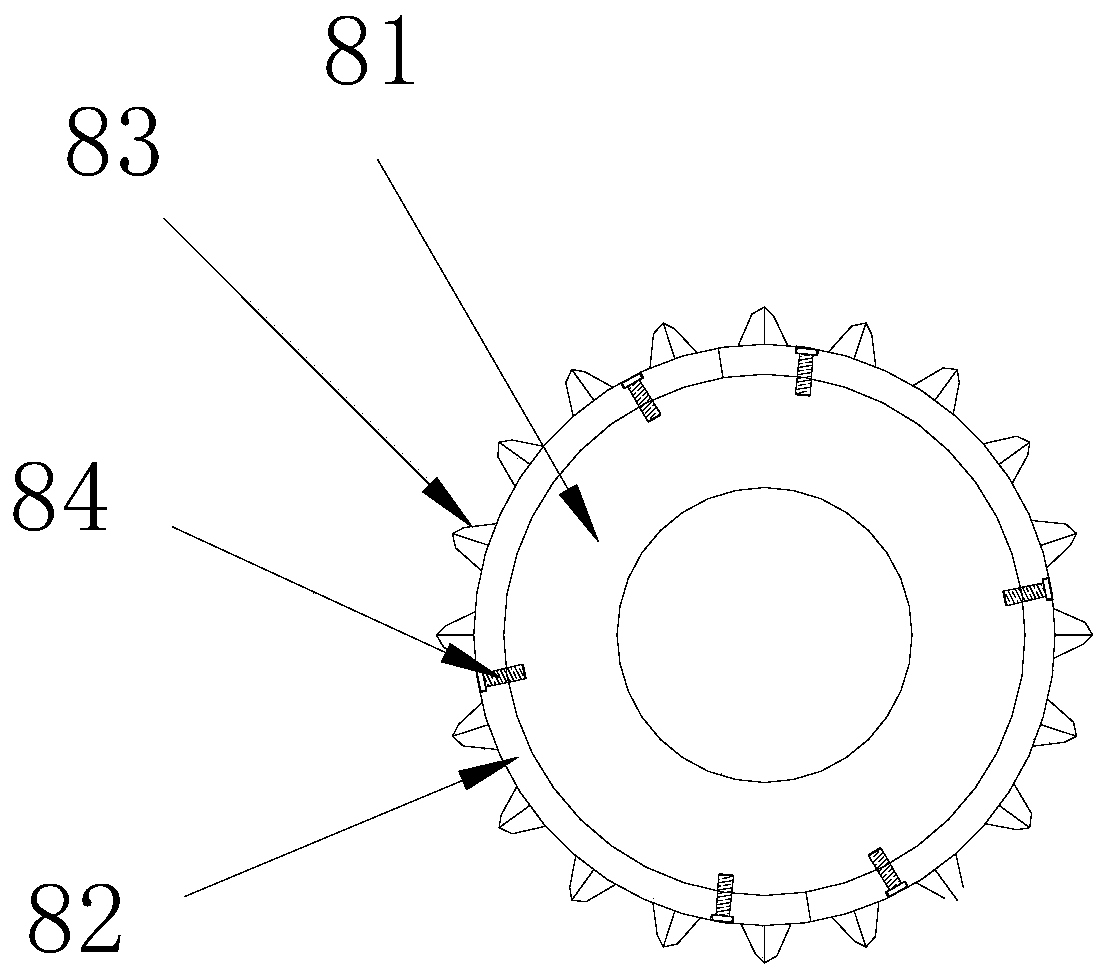

[0034] The wall paint removal mechanism 5 includes a groove-type support shell 6, one side of the groove-type support shell 6 opens outward, and the moving direction of the high-precision one-dimensional translation platform 3 is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com