Urban rainwater pipeline drainage intelligent monitoring device

An intelligent monitoring and pipeline technology, applied in measurement devices, water supply devices, waterway systems, etc., can solve problems such as the increase of the stagnant water area and the inability of the staff to monitor the drainage pipelines all the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

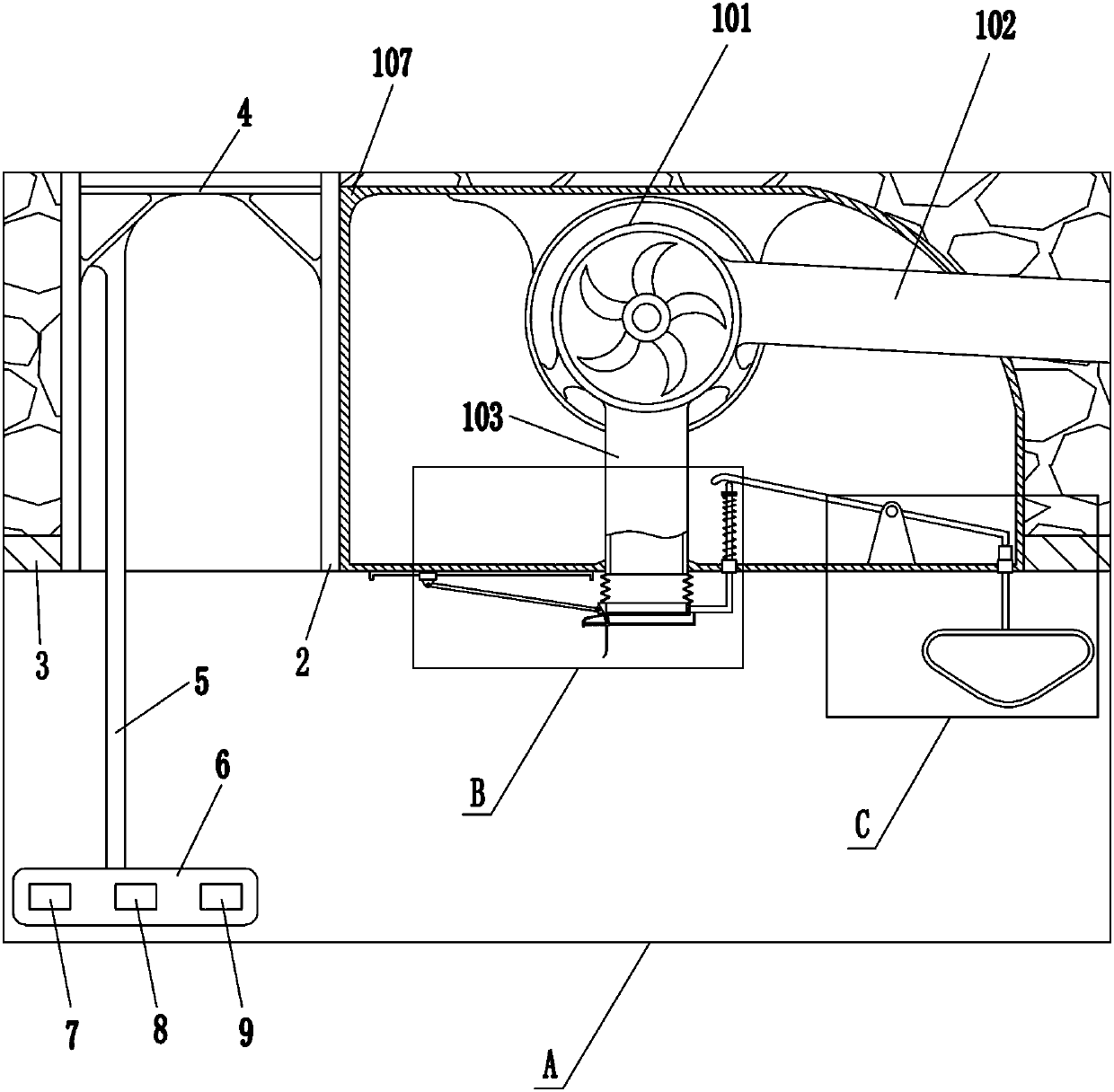

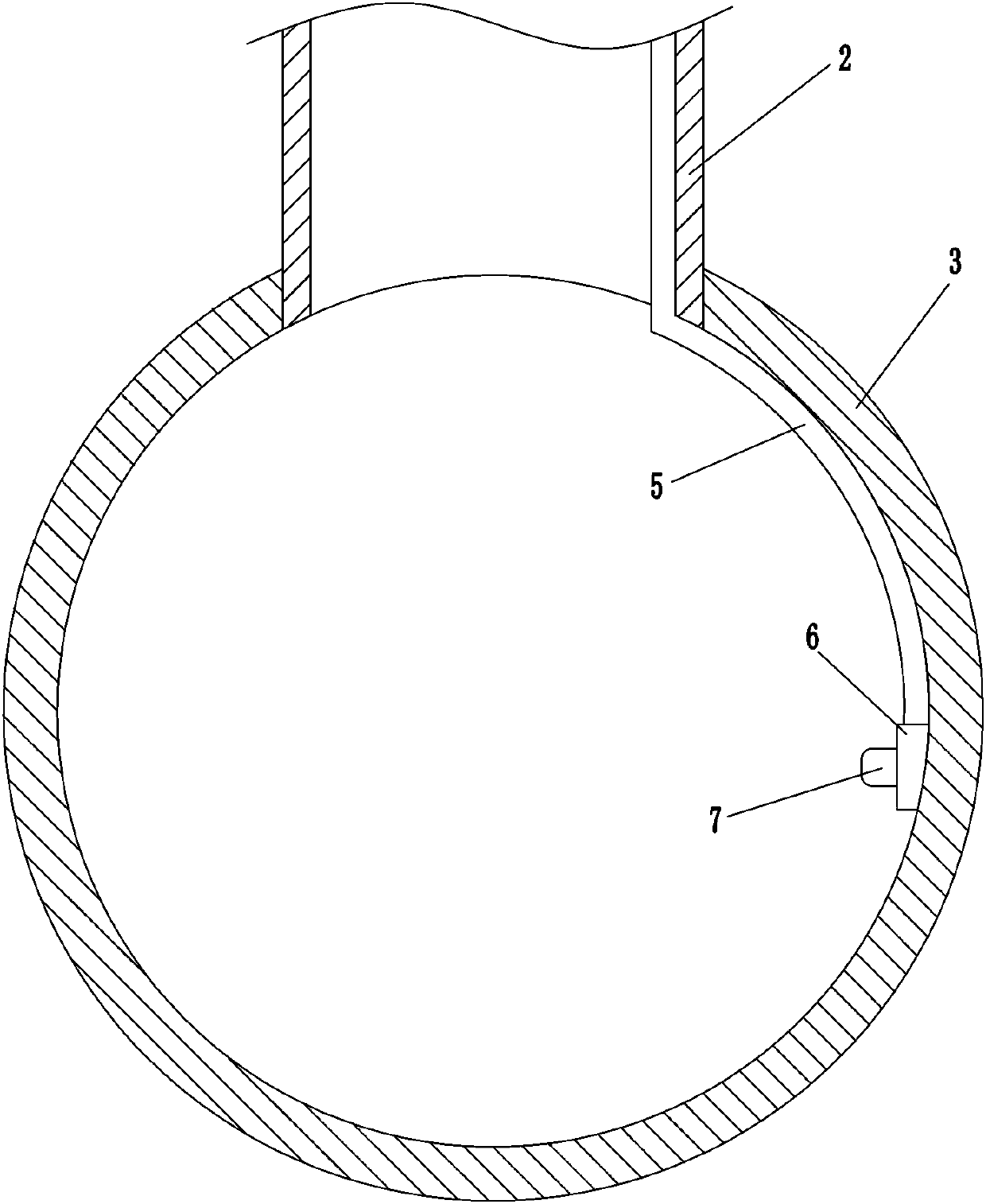

[0024] A kind of urban rainwater pipeline drainage intelligent monitoring device, such as Figure 1-10 As shown, it includes a control room 1, a support frame 4, a fixed rod 5, a mounting plate 6, a first acoustic Doppler flow meter 7, a second acoustic Doppler flow meter 8, and a third acoustic Doppler flow meter 9 and the drainage device 10, the control room 1 includes a GPRS wireless remote control switch circuit breaker, a power supply module, a control module, a first indicator light, a second indicator light, a third indicator light, a fourth indicator light and an LCD display screen, three Two ultrasonic Doppler flowmeter hosts and three storage batteries are installed in the middle of the inner wall of the downpipe 2. The three storage batteries are respectively connected to the three ultrasonic Doppler flowmeter hosts by lines, and the three ultrasonic Doppler flowmeter hosts are all connected to the background server. Through the GPRS wireless connection, the storage...

Embodiment 2

[0026] A kind of urban rainwater pipeline drainage intelligent monitoring device, such as Figure 1-10As shown, it includes a control room 1, a support frame 4, a fixed rod 5, a mounting plate 6, a first acoustic Doppler flow meter 7, a second acoustic Doppler flow meter 8, and a third acoustic Doppler flow meter 9 and the drainage device 10, the control room 1 includes a GPRS wireless remote control switch circuit breaker, a power module, a control module, a first indicator light, a second indicator light, a third indicator light, a fourth indicator light and an LCD display screen, three Two ultrasonic Doppler flowmeter hosts and three storage batteries are installed in the middle of the inner wall of the downpipe 2. The three storage batteries are connected to the three ultrasonic Doppler flowmeter hosts respectively, and the three ultrasonic Doppler flowmeter hosts are all connected to the background server. Through the GPRS wireless connection, the storage battery can supp...

Embodiment 3

[0029] A kind of urban rainwater pipeline drainage intelligent monitoring device, such as Figure 1-10 As shown, it includes a control room 1, a support frame 4, a fixed rod 5, a mounting plate 6, a first acoustic Doppler flow meter 7, a second acoustic Doppler flow meter 8, and a third acoustic Doppler flow meter 9 and the drainage device 10, the control room 1 includes a GPRS wireless remote control switch circuit breaker, a power module, a control module, a first indicator light, a second indicator light, a third indicator light, a fourth indicator light and an LCD display screen, three Two ultrasonic Doppler flowmeter hosts and three storage batteries are installed in the middle of the inner wall of the downpipe 2. The three storage batteries are connected to the three ultrasonic Doppler flowmeter hosts respectively, and the three ultrasonic Doppler flowmeter hosts are all connected to the background server. Through the GPRS wireless connection, the storage battery can sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com