Circuit board detection system and method suitable for automatic production line

A technology for automated production lines and detection systems, applied in electronic circuit testing and other directions, can solve the problems of inability to directly connect automated production lines, manual docking is prone to errors, and improve production efficiency, so as to improve product production quality and traceability, realize The effect of factory automation production and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

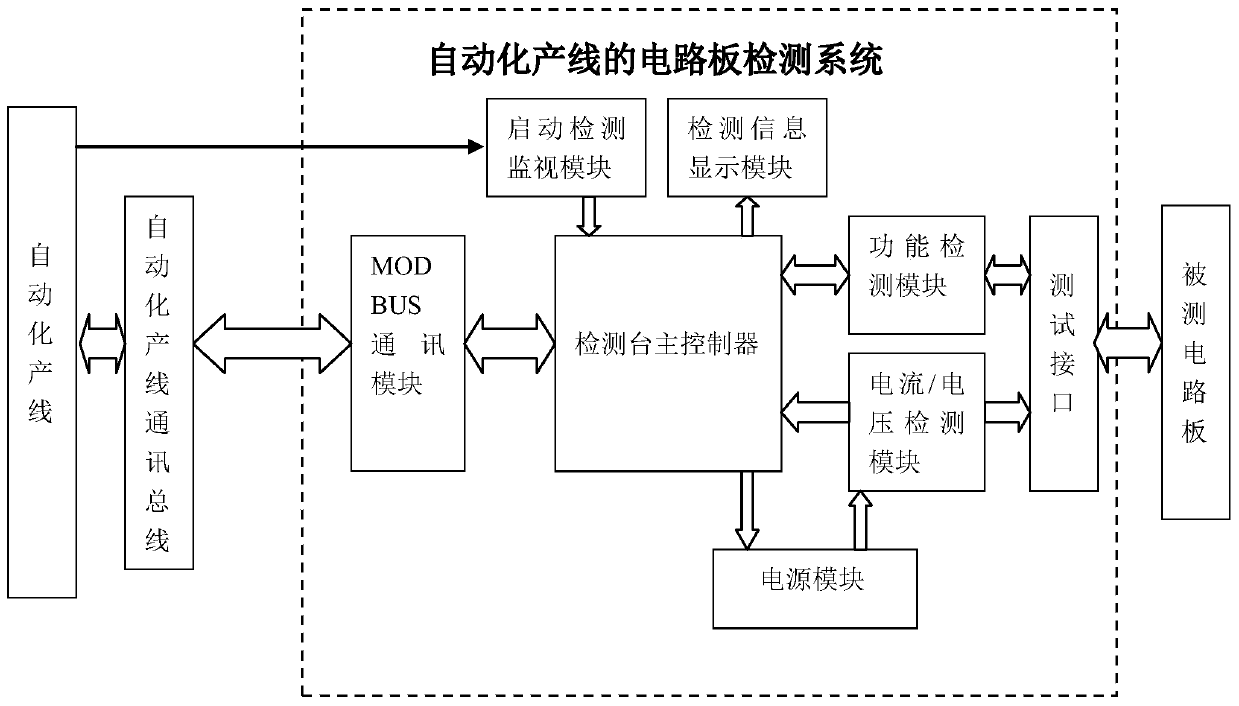

[0023] Such as figure 1 As shown, a circuit board inspection system suitable for automated production lines, including a start-up detection monitoring module, a detection station main controller module, a detection information display module, a function detection module, a current and voltage detection module, a test interface, a communication module, and a power supply module .

[0024] Among them, the main controller module of the detection station is electrically connected with the communication module, the start-up detection monitoring module, the detection information display module, the function detection module, and the current and voltage detection module, and the test interface is respectively electrically connected with the function detection module and the current and voltage detection module. The modules are respectively electrically connected with the main controller module of the detection station and the current and voltage detection module.

[0025] Specifical...

Embodiment 2

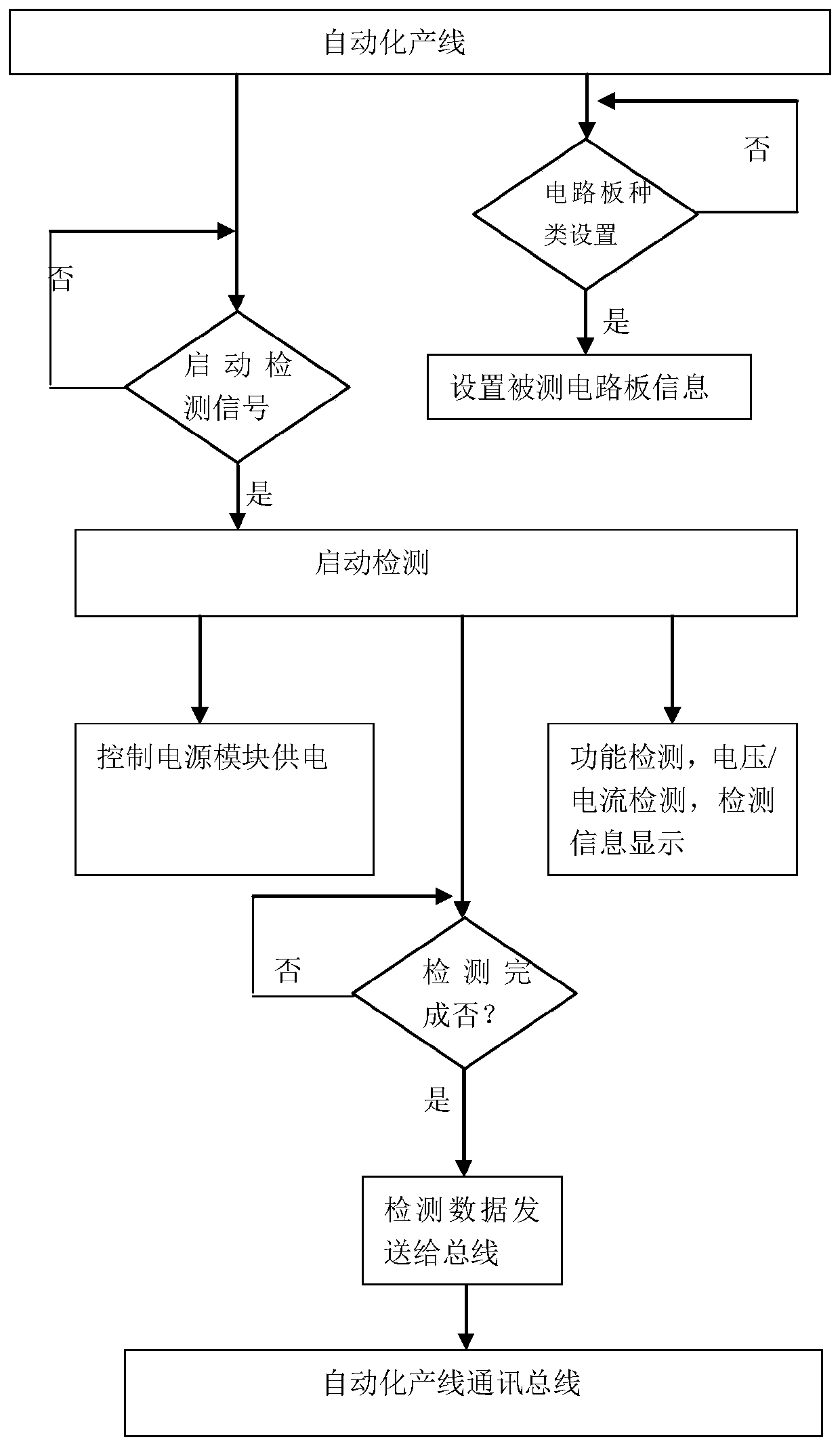

[0032] Such as figure 2 As shown, a circuit board detection method applicable to an automated production line is realized by the above-mentioned circuit board detection system applicable to an automated production line, and specifically includes the following steps:

[0033] A. The communication module receives the detection information of the tested circuit board from the communication bus of the automatic production line, and sends the detection information to the main controller module of the detection station; wherein, the detection information includes the type information of the tested circuit board; specifically, In this embodiment, the automated production line communication bus sends detection information to the communication module only when the type of the circuit board to be tested or the detection item needs to be modified, thereby starting the subsequent detection program;

[0034] B. The main controller module of the detection station prepares the detection pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com