Method for determining optimal operation parameter of double-field coupling dewatering device

A dual-field coupling and dehydration device technology, which is applied in the fields of electric/magnetic dehydration/demulsification, mechanical dehydration/demulsification, chemical process analysis/design, etc., can solve the problems affecting the oil-water separation effect of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

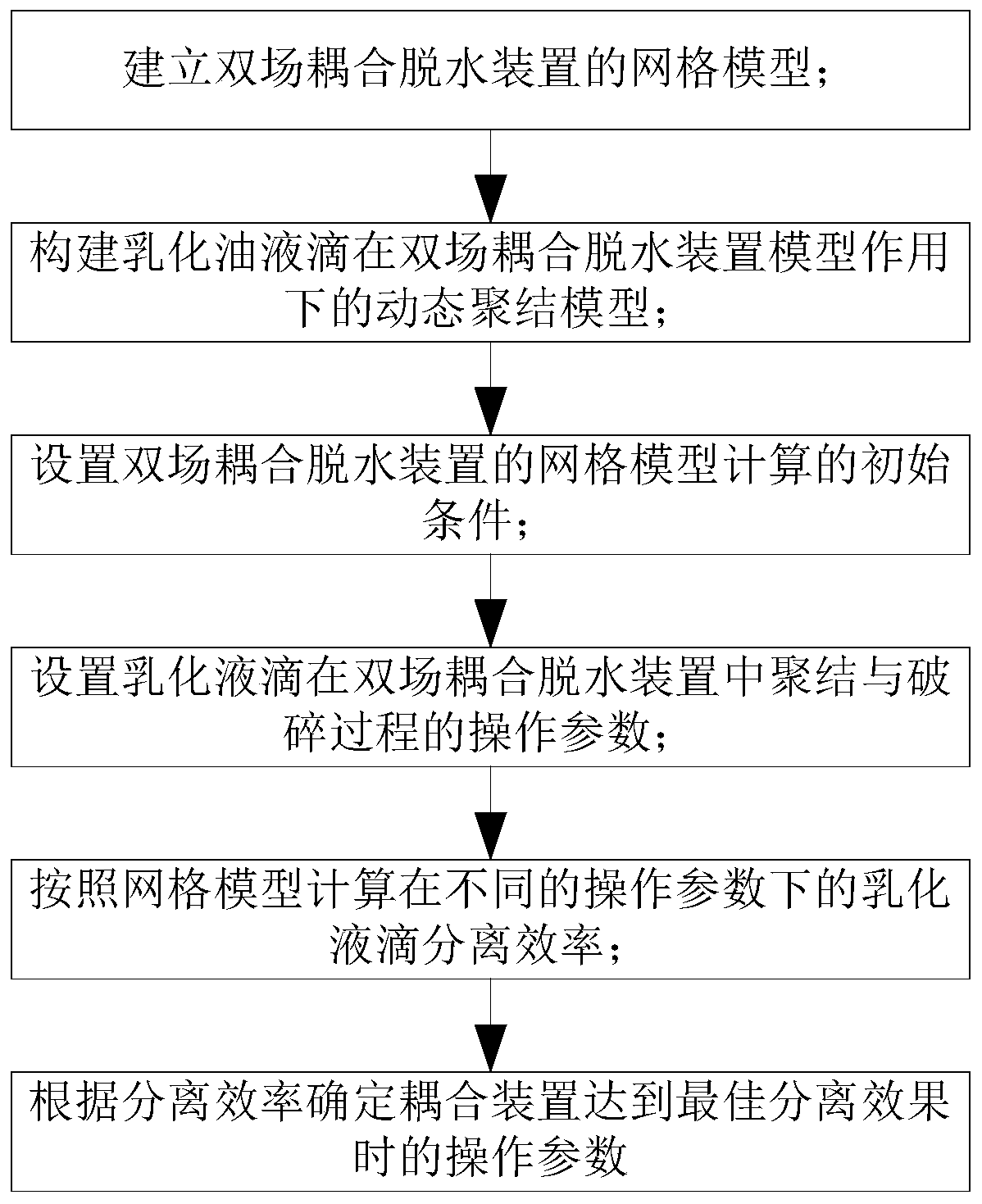

Method used

Image

Examples

Embodiment 1

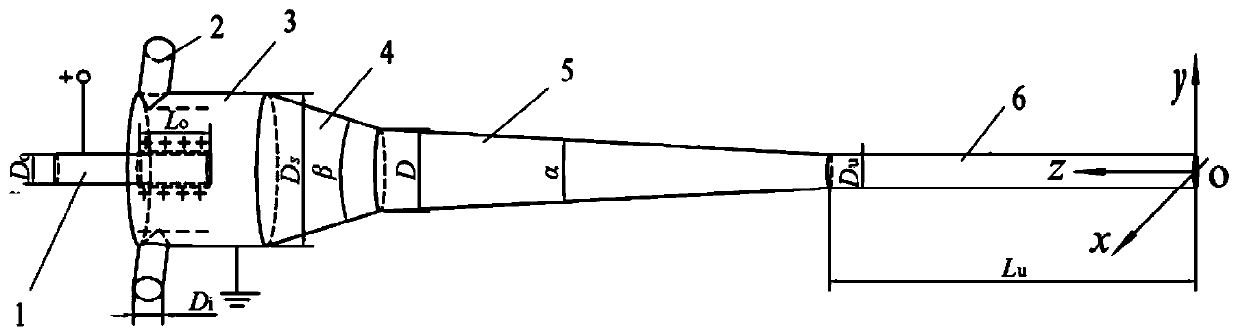

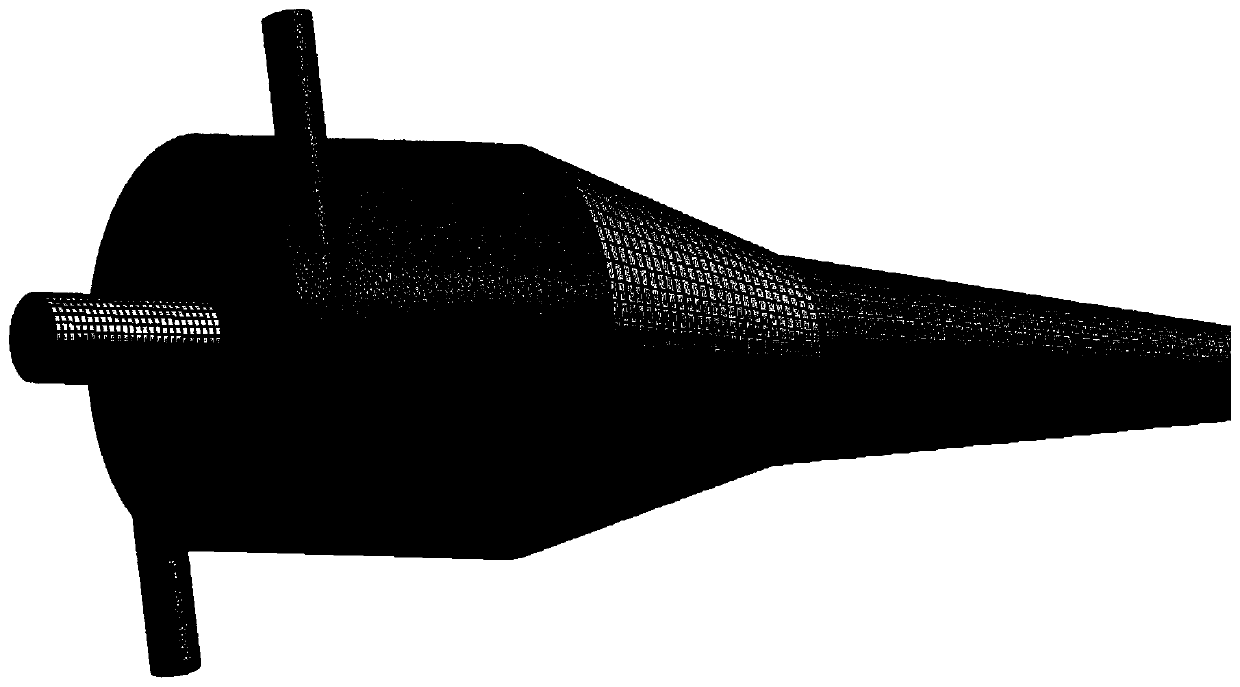

[0114] like figure 1 as shown, figure 1 is a dual-field coupling dehydration device model, figure 1 A multi-physics coupling model of the dehydration device is given. The double-field coupling dehydration device includes an overflow pipe, an oil inlet, a swirl chamber, a large cone section, a small cone section, and an underflow pipe. The overflow pipe is connected to the power supply The positive pole, the surface of the swirl chamber is grounded as the negative pole, and a coaxial cylindrical electric field (red area in the figure) is formed in the swirl chamber. The emulsified droplets coalesce and increase under the action of the electric field, and realize rapid oil-water separation under the action of the swirl field. .

[0115] An overflow pipe and an oil inlet are arranged on the swirl chamber, and the oil inlet is arranged on the outer wall of the swirl chamber. Enter the swirl chamber at a certain speed, and can rotate and flow along the inner wall of the swirl ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com