Bolt pose detectors and bolt pose detection tightening device

A detector and pose technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult to ensure the axis of the bolt and the axis of the tightening shaft, small inclination angle of the bolt, identification and detection, etc., to improve the quality of bolt assembly and assembly efficiency, improved accuracy, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

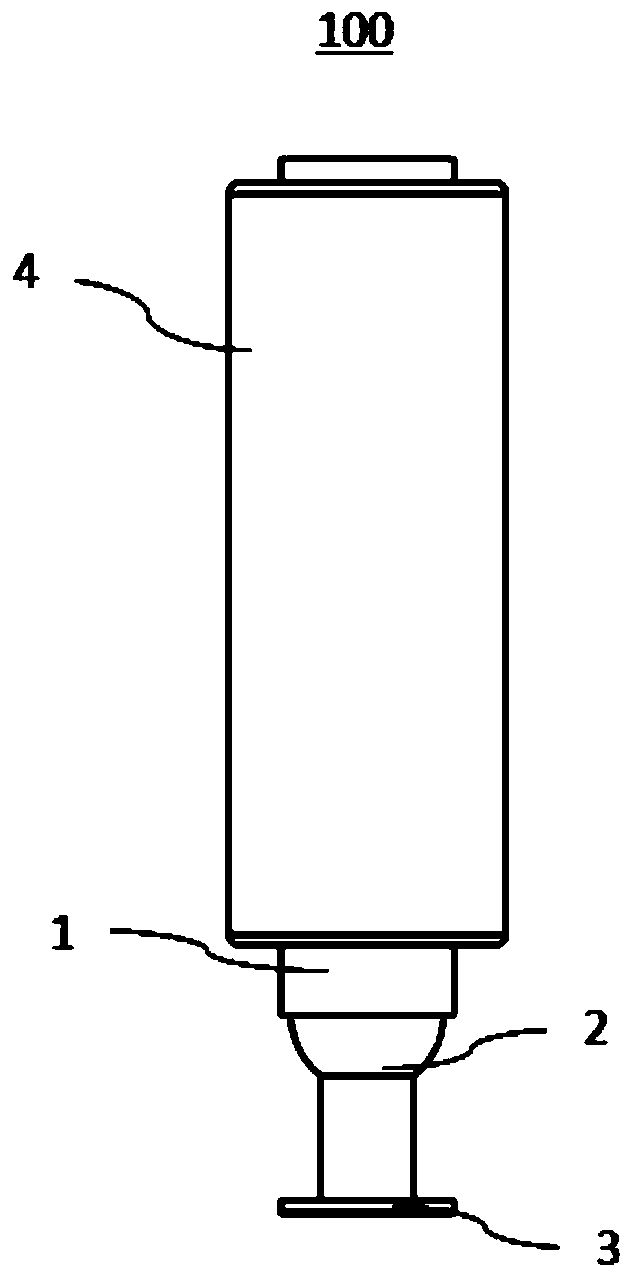

[0044] Refer below Figure 1 to Figure 4 The bolt pose detector 100 according to the embodiment of the first aspect of the present invention will be described.

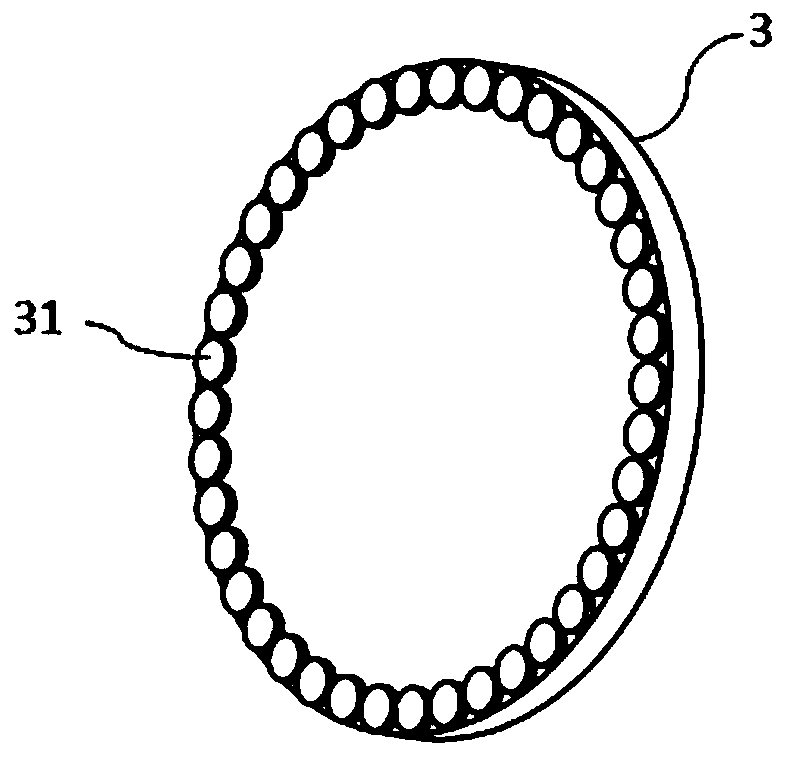

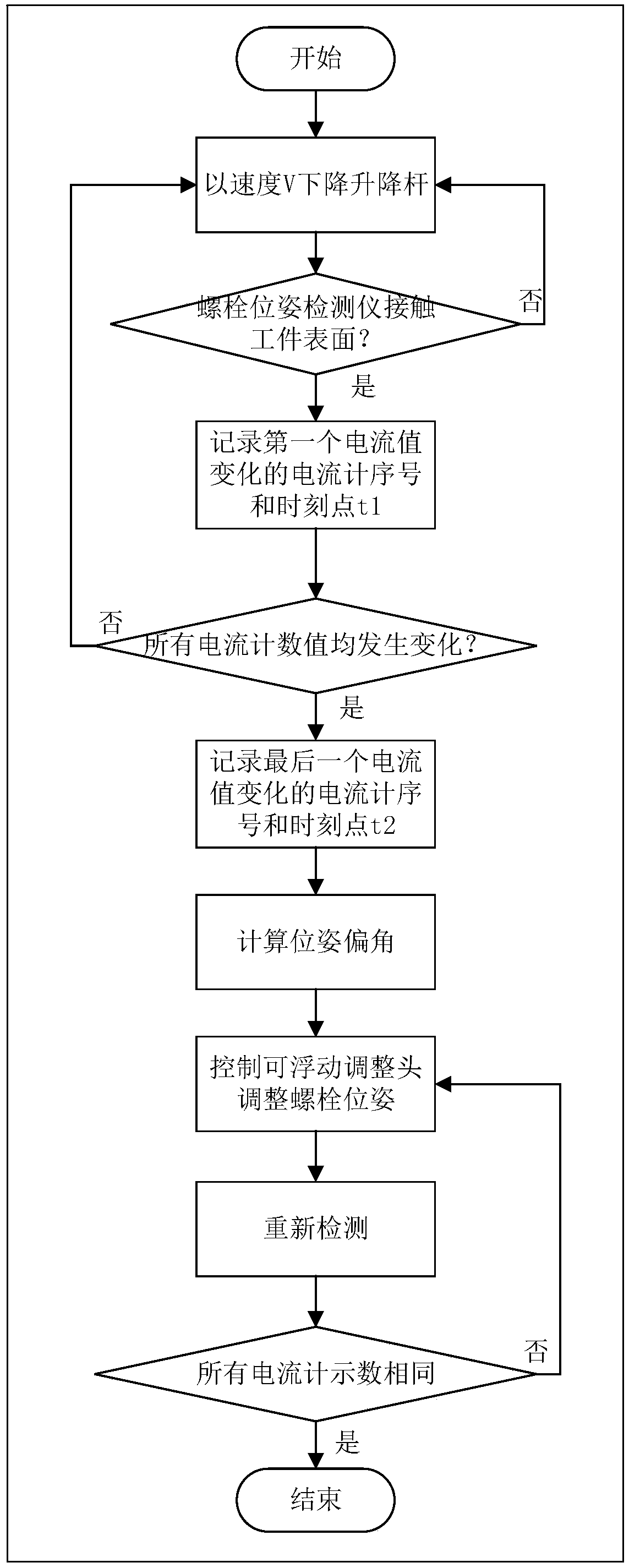

[0045] Such as figure 1 and figure 2 As shown, the bolt pose detector 100 according to the embodiment of the first aspect of the present invention includes a lifting rod 1 , a floating adjustment head 2 and a pose detection piece 3 . Among them, the lifting rod 1 is vertically arranged and can be used for lifting movement; the upper end of the floating adjustment head 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com