An automatic antique brick press machine

An antique brick and brick press technology, which is applied in the directions of forming indenters, ceramic forming machines, manufacturing tools, etc., can solve the problems of difficulty in producing antique pattern tiles, difficulty in one-time molding, and low production efficiency. Easy maintenance and cleaning, high production efficiency and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

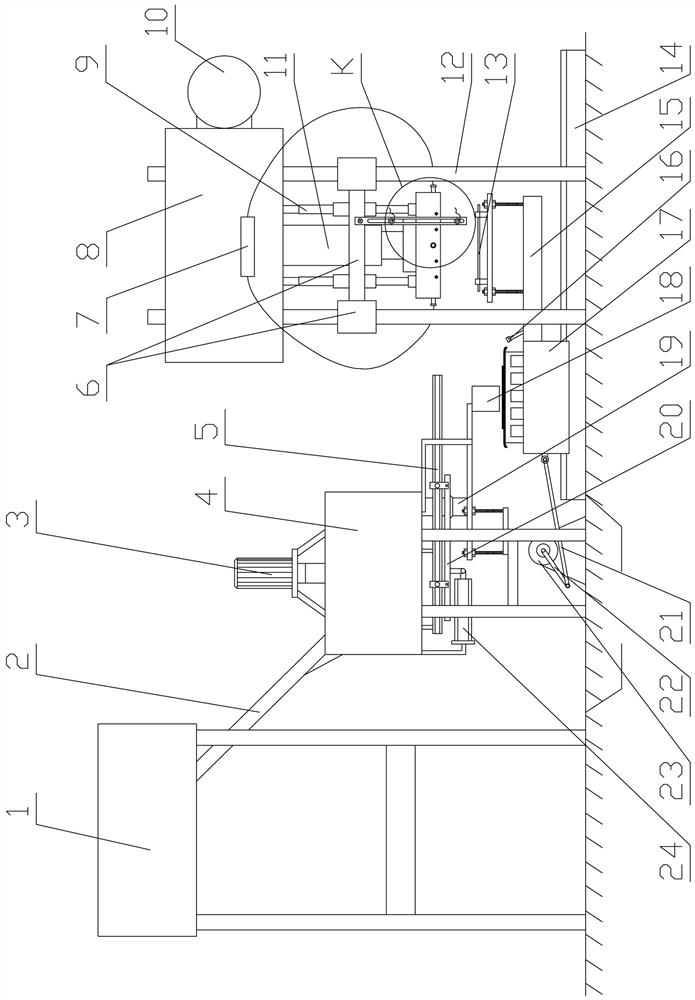

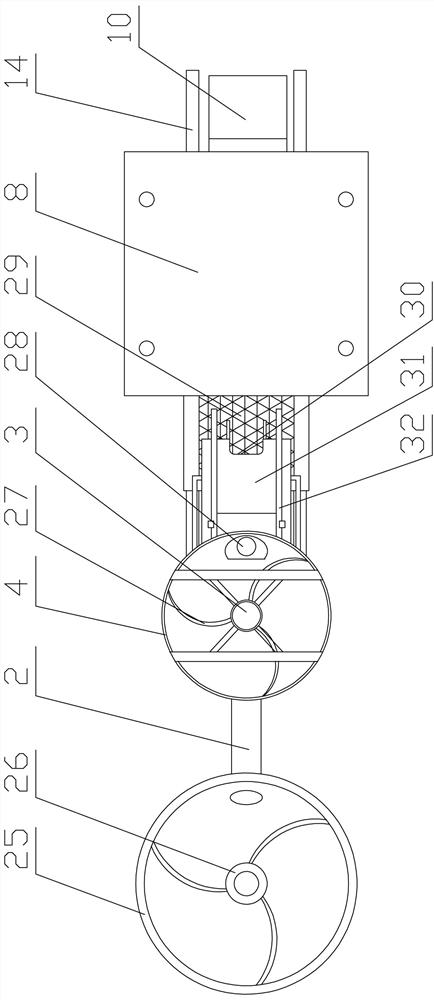

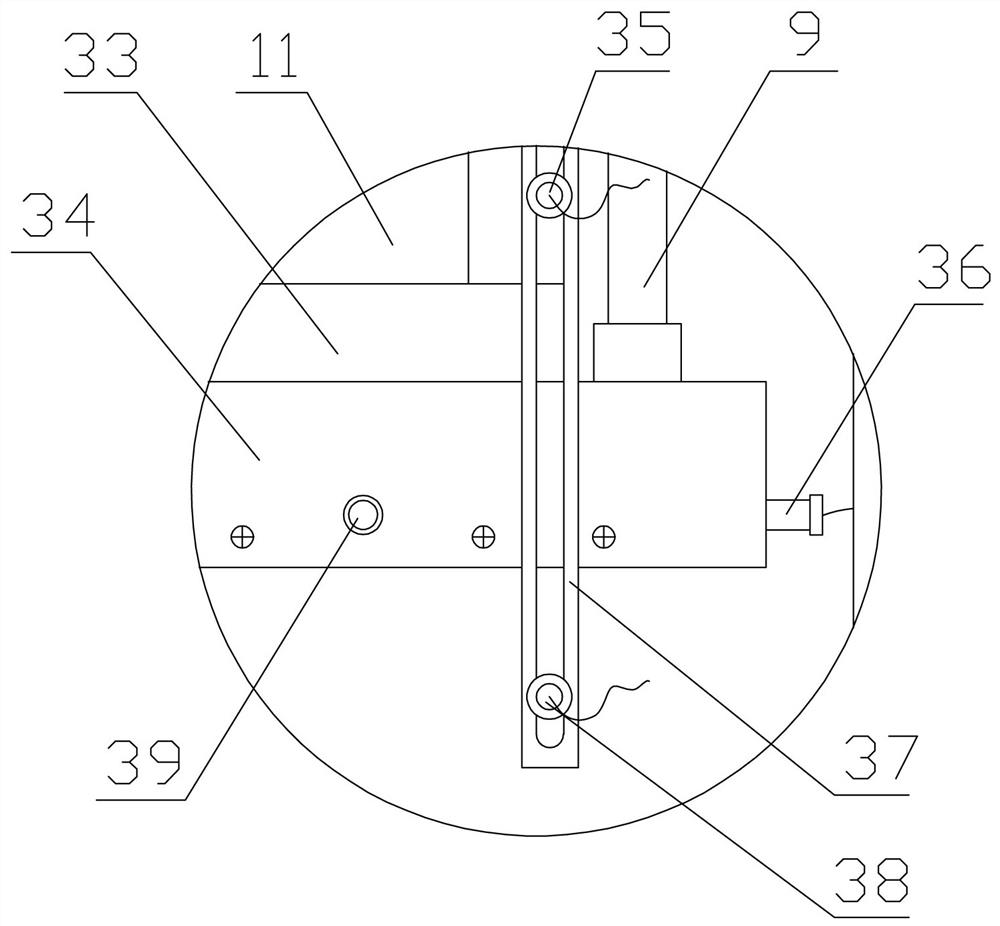

[0027] see Figure 1-Figure 8 , the present invention is an automatic antique brick press, including a feeding system and an antique brick pressing system, the feeding system includes a mixing device 1 and a feeding device, and the mixing device feeds the premixed material through an inclined trough 2 Output to the feeding device, the feeding device supplies the pressed brick raw materials to the antique brick pressing system, the antique brick pressing system includes a supporting frame, the upper part of the supporting frame is equipped with a mounting seat 8, and the bottom of the mounting seat is downwardly equipped with a mold Core drive oil cylinder 11 and mold frame drive oil cylinder 9, the piston rod end of mold core drive oil cylinder is connected with brick pressing mold core 33, and the piston rod end of mold frame drive oil cylinder is connected with brick pressing mold frame 34, and brick pressing mold frame is contained in pressing brick mold frame. The peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com