Micro crawler tractor chassis control system based on CAN bus

A CAN bus, control system technology, used in circuits or fluid pipelines, transportation and packaging, vehicle components, etc., can solve the problems of a large number of wiring harnesses, difficulty in fault diagnosis, and difficulty in expanding new systems, reducing the number of wiring harnesses and facilitating The effect of fault diagnosis, easy development and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

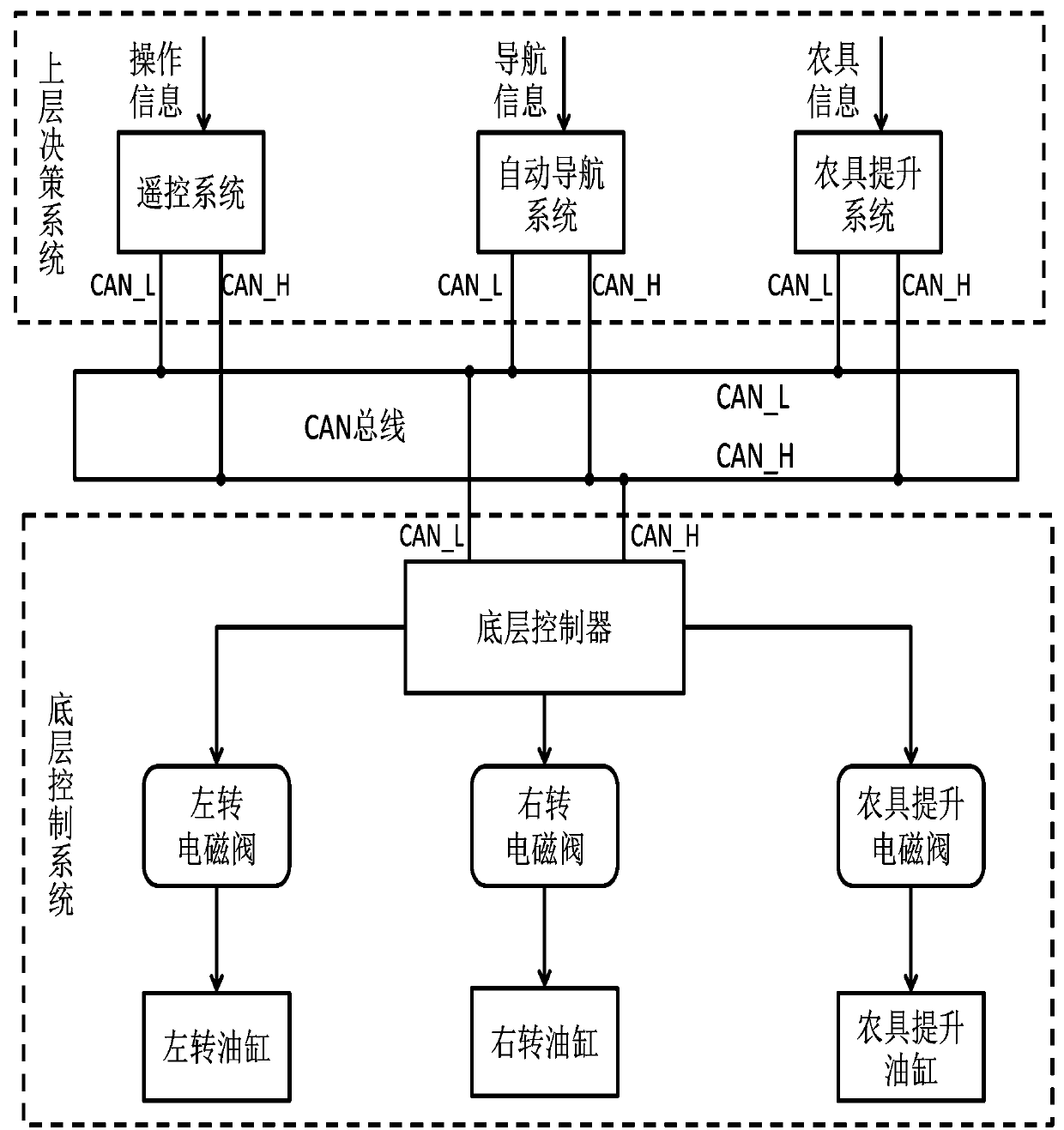

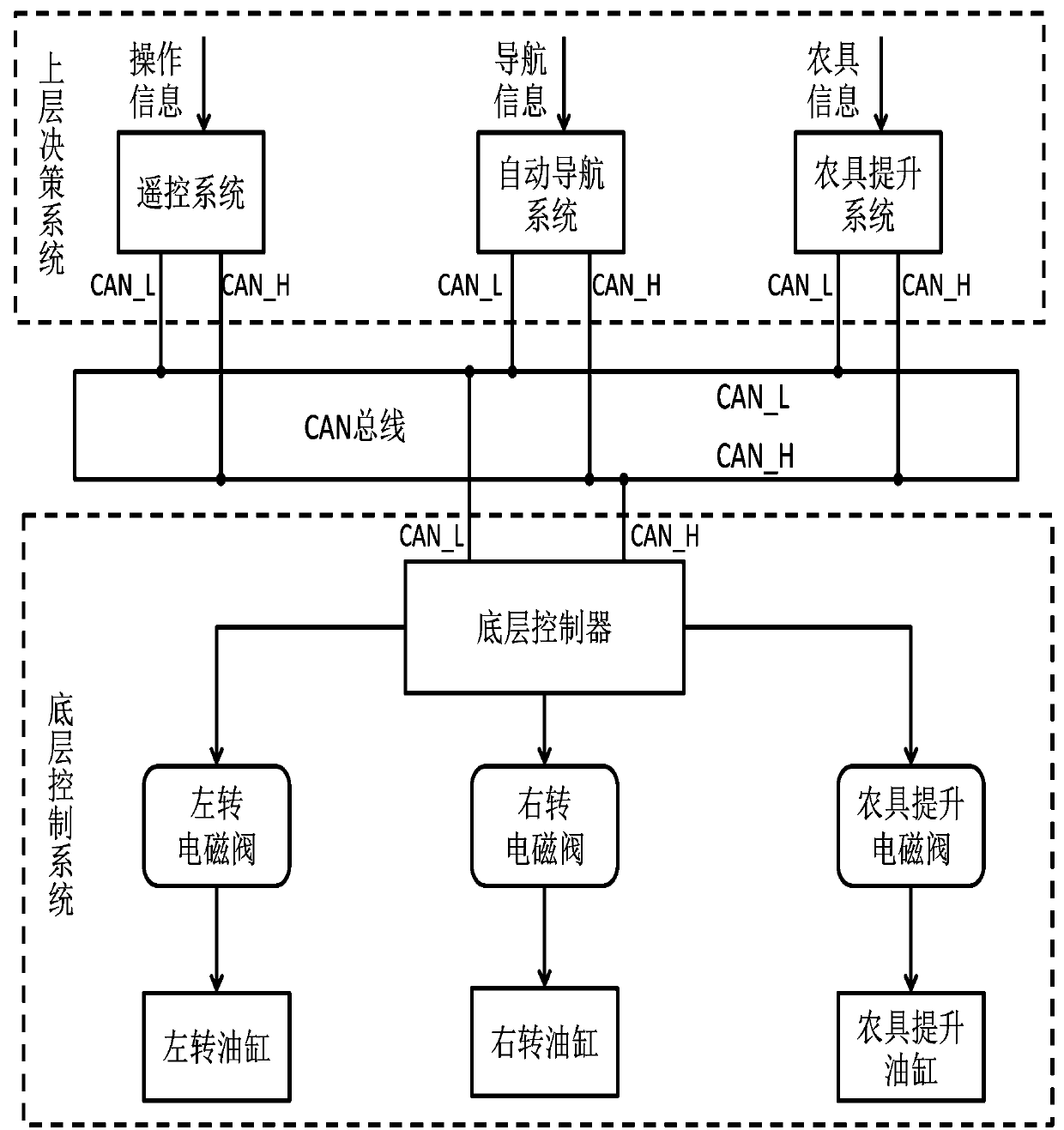

[0009] The invention discloses a CAN bus-based miniature crawler tractor chassis control system, including a remote control system, an automatic navigation system, an agricultural implement lifting system, a CAN bus, a bottom controller, a left-turn solenoid valve, a right-turn solenoid valve, and an agricultural implement lift solenoid valve , Left-turn oil cylinder, right-turn oil cylinder, farm tool lifting oil cylinder. The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, the upper-level decision-making system of the miniature crawler tractor: the remote control system, the automatic navigation system, and the farm tool lifting system are responsible for decision-making, and the execution instructions after the decision-making are sent to the CAN bus in the form of CAN messages. The bottom controller reads the corresponding instruction information according to the order of priori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com