Gear position determining and system of ATM transmission and related device

A transmission and gear technology, applied in the field of AMT transmission gear adjustment, can solve the problems of unsuccessful gear shifting, abnormal wear of key parts of the transmission, wear of mechanical parts, etc. The effect of blocking smoothness and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

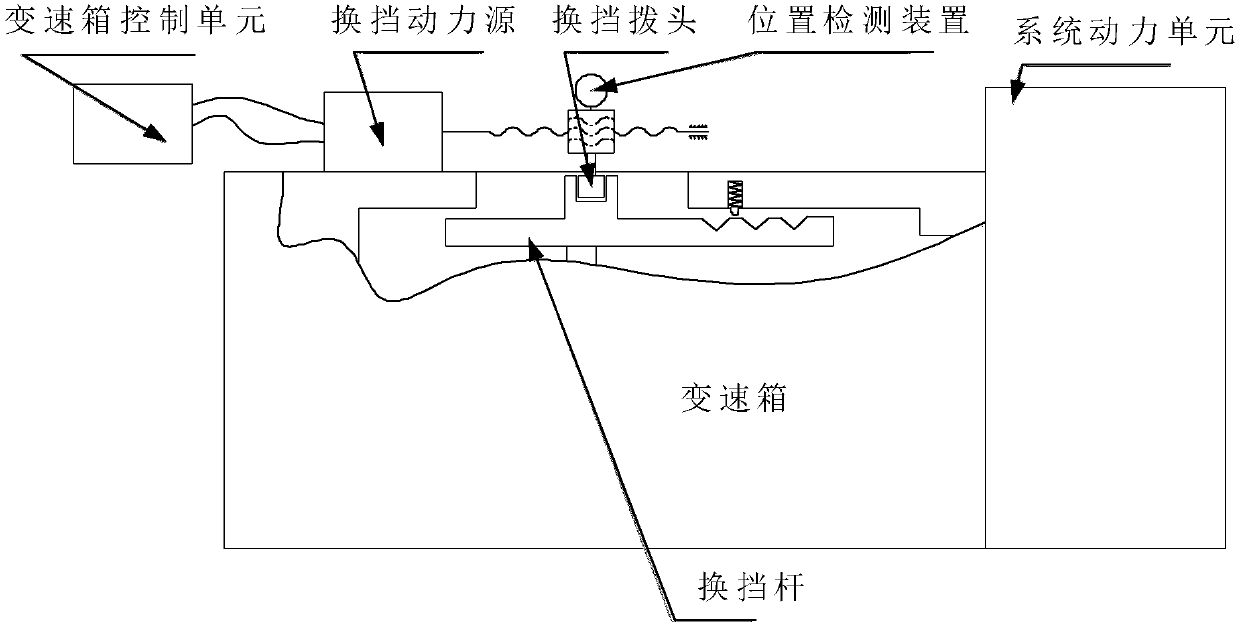

[0063] See figure 1 , figure 1 It is a schematic diagram of the actual structure of an AMT gearbox.

[0064] It usually includes a gearbox control unit, a shift power source, a shift knob, a shift lever, a gearbox and a system power unit, etc., wherein the shift knob is provided with a position detection device for detecting the real-time position of the shift knob. from figure 1 It can be seen in the figure that there are limit devices on the left and right sides of the shifting head to limit the shifting head to move only in a fixed area, and the movement of the shifting head also drives the shift lever connected to it. Corresponding movement occurs, and there are three pits on the right side of the shift lever, among which there is a fixed-position shifting device near the leftmost pit, which is used to switch between the three pits as the position of the shift lever changes. The movement occurs in the pit, and the three pits correspond to three different gears.

[0065...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com