A kind of polyurethane wood grain powder coating for aluminum profiles

A powder coating and polyurethane technology, applied in polyurea/polyurethane coatings, powder coatings, anti-corrosion coatings, etc., can solve the problem of not paying attention to the surface gloss of aluminum profiles and the annual performance of aluminum profiles, affecting the surface brightness of aluminum profiles, and dust contamination And other problems, to achieve the effect of improving anti-corrosion performance, preventing air bubbles or falling off, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 A kind of surface treatment process of aluminum profiles

[0054] Described technique comprises the following steps:

[0055] (1) Surface pretreatment of aluminum profiles

[0056] The pretreatment is to clean the aluminum profile, remove the dust on the surface, and obtain the pretreated aluminum profile;

[0057] (2) Soaking treatment of aluminum profiles

[0058] The soaking is to put the pretreated aluminum profile in the step (1) into the soaking solution for 10-15 minutes to soak, so as to obtain the soaked aluminum profile;

[0059] The soaking solution is a mixture of sodium bicarbonate solution with a mass fraction of 5% and a sodium hydroxide solution with a mass fraction of 3%, and the volume ratio of the two is sodium bicarbonate solution: potassium hydroxide solution is 1:4;

[0060] (3) Drying treatment of aluminum profiles

[0061] The drying process is to place the soaked aluminum profile in step (2) in a vacuum drying oven, and dry it f...

Embodiment 2

[0070] Embodiment 2 A kind of aluminum profile surface treatment process

[0071] Described technique comprises the following steps:

[0072] (1) Surface pretreatment of aluminum profiles

[0073] The pretreatment is to clean the aluminum profile, remove the dust on the surface, and obtain the pretreated aluminum profile;

[0074] (2) Soaking treatment of aluminum profiles

[0075] The soaking is to put the pretreated aluminum profile in the step (1) into the soaking solution for 15 minutes to soak for 15 minutes to obtain the soaked aluminum profile;

[0076] The soaking solution is a mixture of sodium bicarbonate solution with a mass fraction of 8% and a sodium hydroxide solution with a mass fraction of 5%, and the volume ratio of the two is sodium bicarbonate solution: potassium hydroxide solution is 2:4;

[0077] (3) Drying treatment of aluminum profiles

[0078] The drying process is to place the soaked aluminum profile in step (2) in a vacuum drying oven, and dry it ...

Embodiment 3

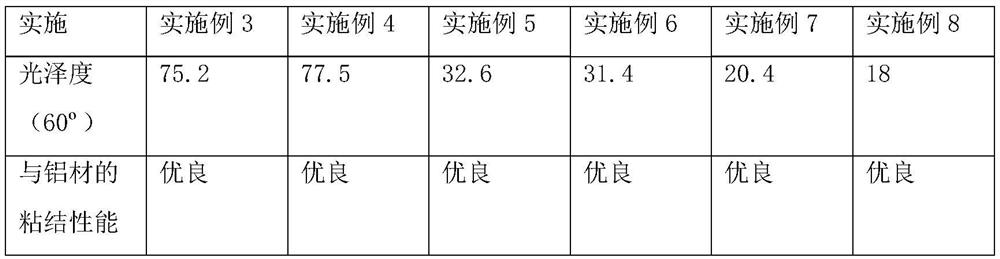

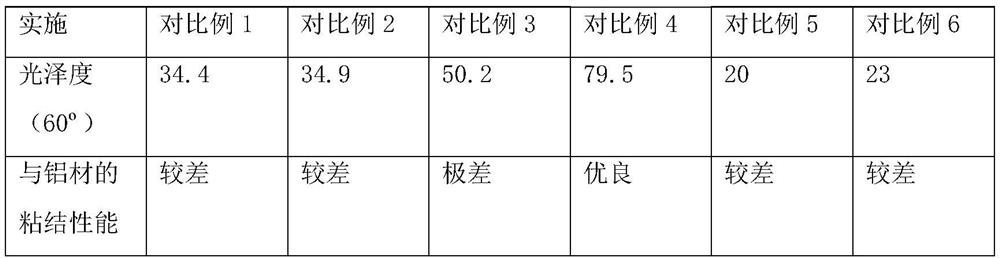

[0087] Embodiment 3 A kind of polyurethane wood grain powder coating for aluminum profiles

[0088] Include the following components in parts by weight: allnex 2870-05 parts, allnex 2818-02 parts, allnex 2876-01 parts, curing agent 5 parts, precipitated barium sulfate 6 parts, leveling agent 0.5 parts, antioxidant 0.5 parts, 0.2 parts of stannous octoate and stannous oxalate with a mass ratio of 1:1, and 5 parts of carbon black.

[0089] The curing temperature of the polyurethane wood grain powder coating for aluminum profiles is 155° C., and the curing time is 14 minutes.

[0090] The polyurethane wood-grain powder coating for aluminum profiles is sprayed by high-voltage static electricity, the high-voltage static electricity is 70KV high-voltage static electricity, and the thickness of the sprayed film is 80 microns.

[0091] The preparation method of the polyurethane wood grain powder coating for aluminum profiles specifically comprises the following steps:

[0092] (1) F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com