Sewing machine traction device

A traction device, sewing machine technology, applied in sewing machine control devices, sewing machine components, program-controlled sewing machines, etc., can solve problems such as loud noise, hidden danger of synchronous belts, oil pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] In conjunction with the accompanying drawings, the present invention is described in detail.

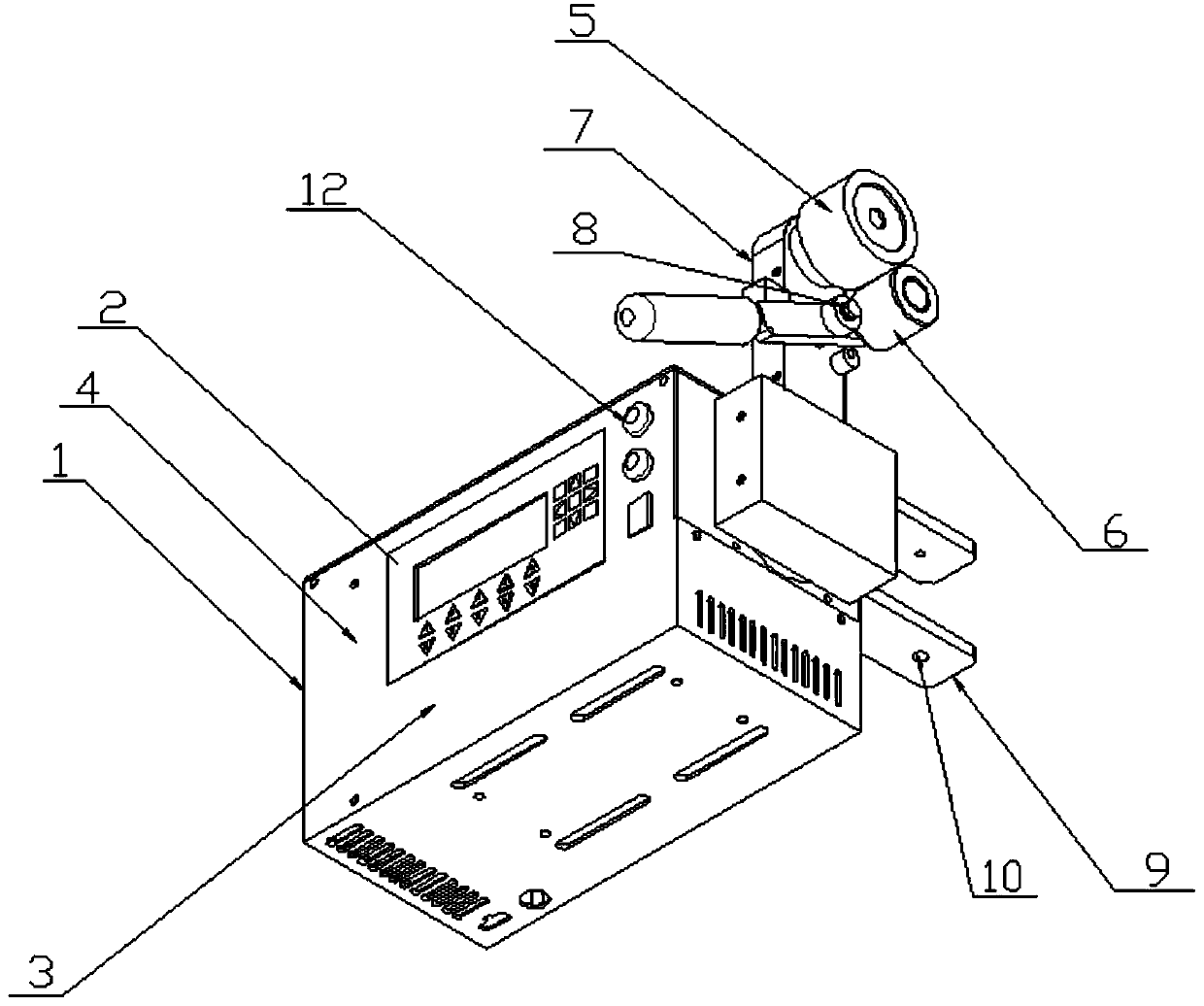

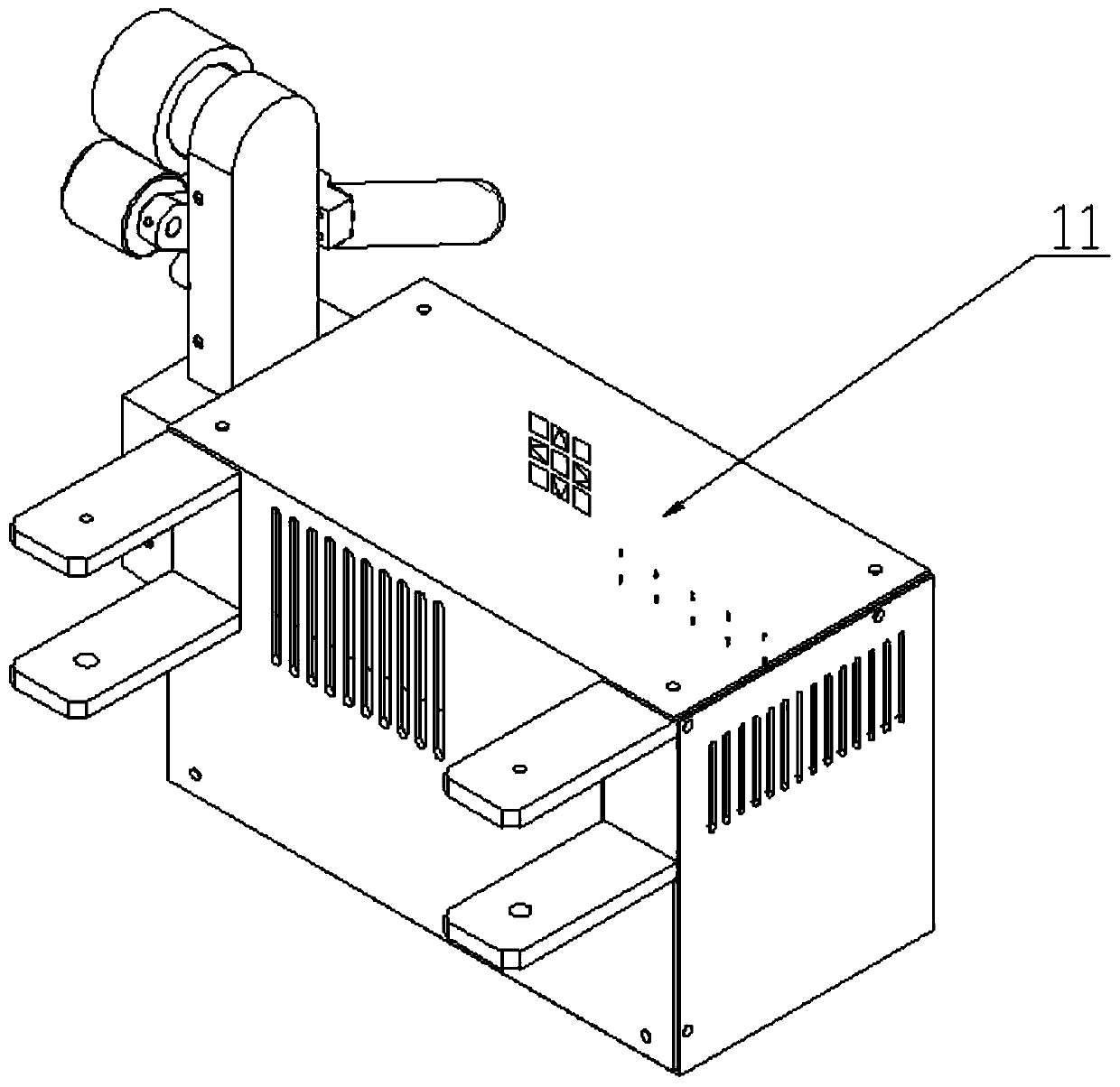

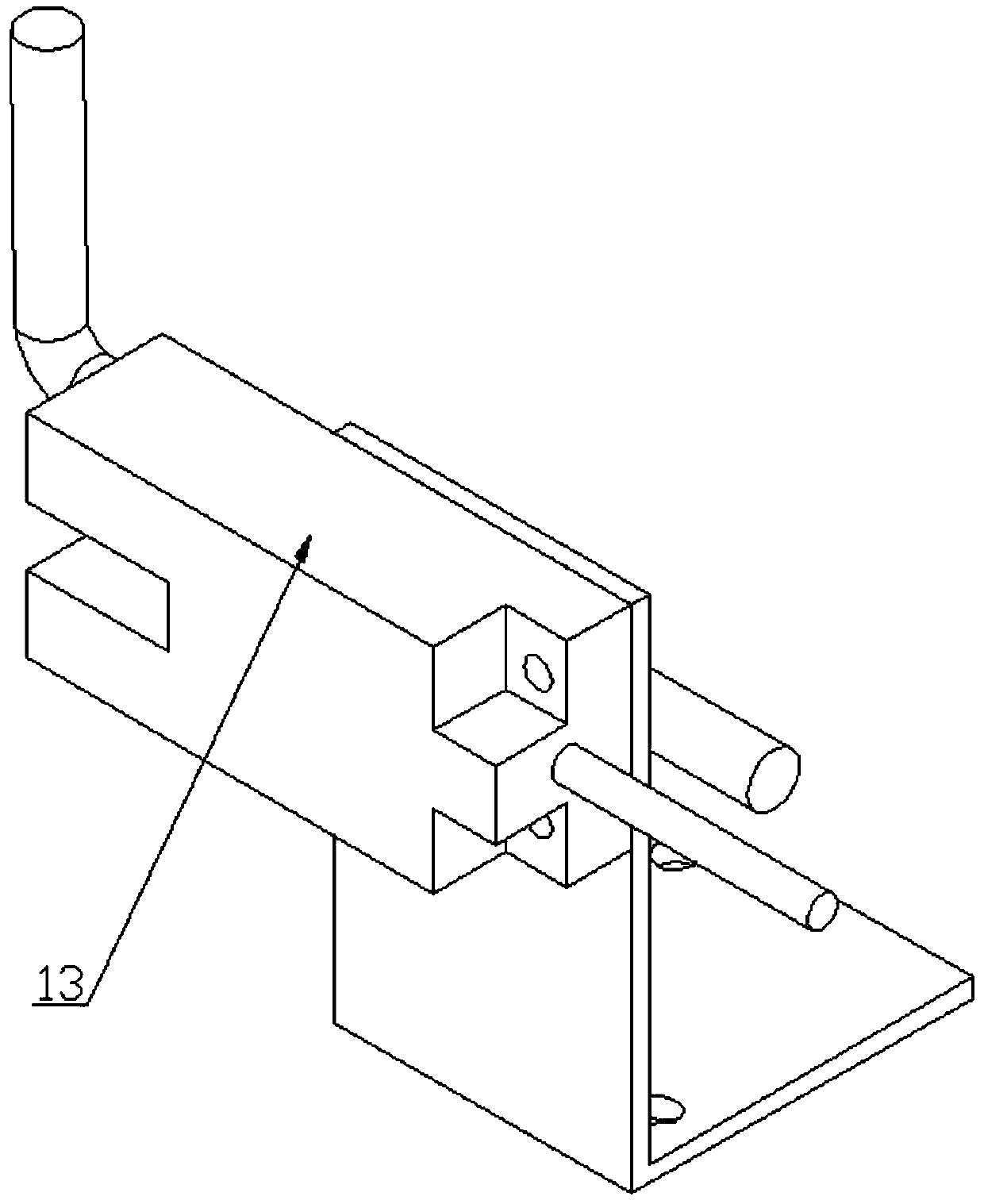

[0020] The present invention provides a sewing machine traction device during specific implementation, comprising a traction device body 1, a program control board 2 is provided on the front side of the traction device body 1, a switching power supply 3 is provided below the program control board 2, The left side of the program control panel 2 is provided with a stepper motor driver 4, the rear side of the program control panel 2 is provided with a stepper motor 11, and the outside of the traction device body 1 is provided with a driving rubber wheel 5 and a driven wheel. Rubber wheel 6, the traction device body 1 is provided with a synchronous wheel 7, the active rubber wheel 5 is arranged on the synchronous wheel 7, and a connecting shaft 8 is arranged betw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap