Prestressed jacking method of main cable saddle of suspension bridge

A prestressed, main cable saddle technology, applied to suspension bridges, bridge forms, bridges, etc., to achieve the effect of leaving no hidden dangers in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

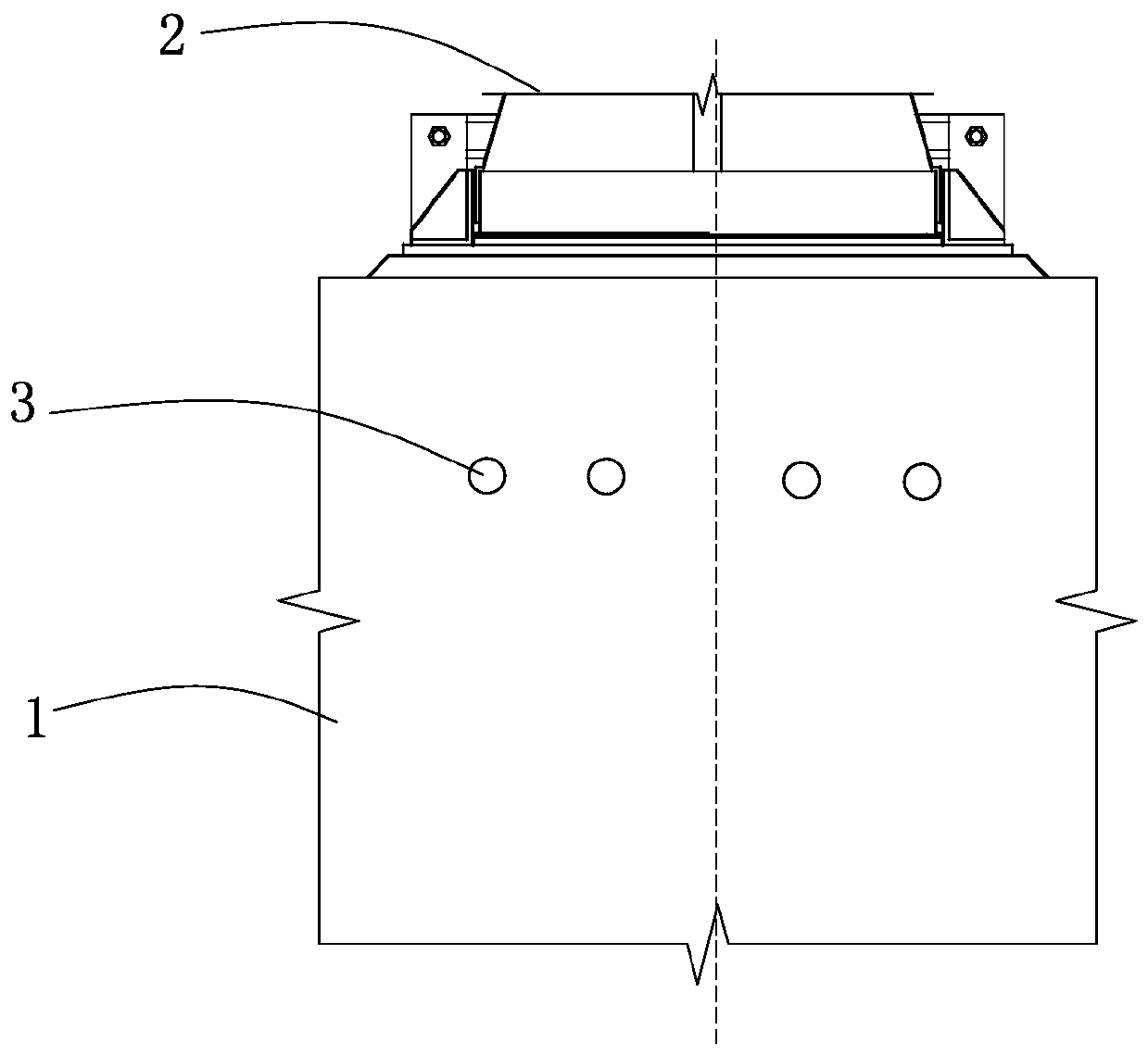

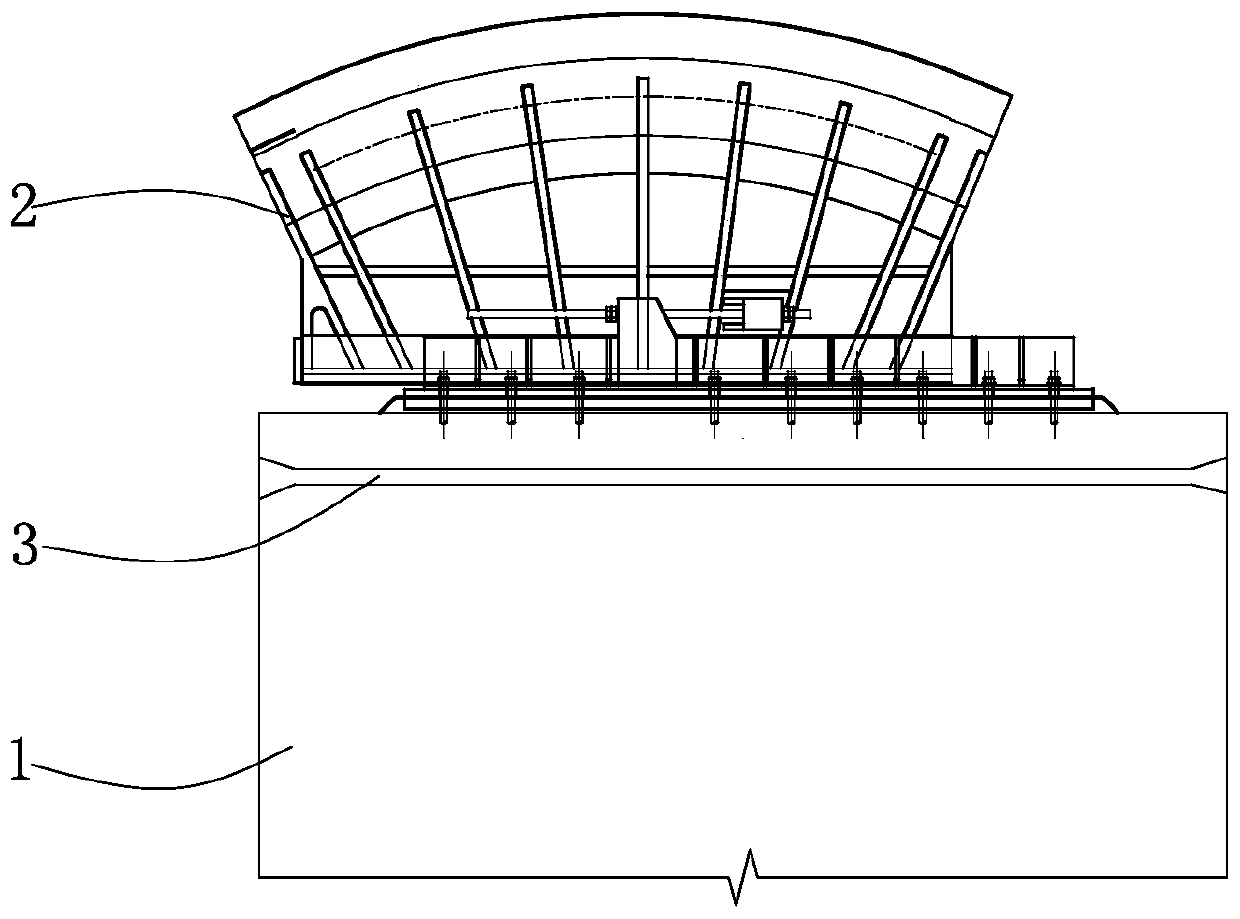

[0021] (1) if figure 1 , figure 2 As shown, the top of the bridge tower 1 is provided with a main cable saddle 2 . When adjusting the main cable shape of the suspension bridge, it is necessary to push the main cable saddle along the direction of the bridge. When the present invention is pouring the bridge tower, 4 prestressed pipelines 3 running through the bridge tower concrete along the bridge direction are preset in the tower top concrete. There is a certain distance between the two prestressed pipes in each group, and the two groups of prestressed pipes are arranged symmetrically on both sides of the bridge tower along the centerline of the 1st bridge.

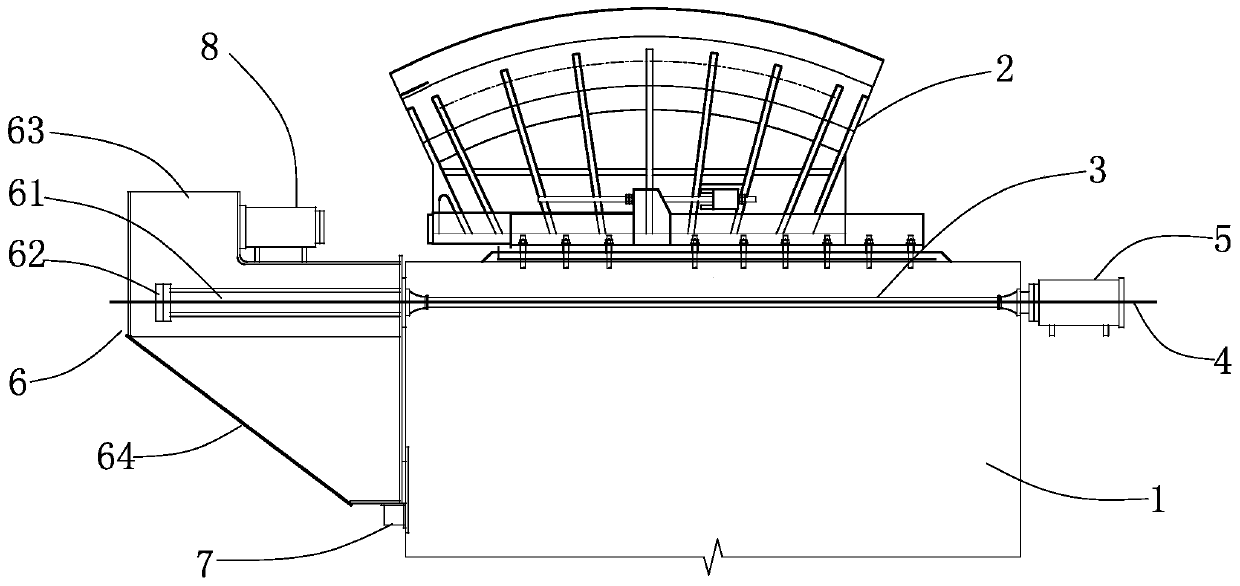

[0022] (2) if image 3 , Figure 4 As shown, after the main cable of the suspension bridge is erected and before the main cable type is adjusted, the prestressed steel strands 4 are respectively inserted into the four prestressed pipes 3, and the four prestressed steel strands 4 are directed towards the middle span of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com