Asymmetric double-buoy floating breakwater

A floating breakwater and double buoy technology, applied in the directions of breakwaters, jetties, embankments, etc., can solve the problems of unsatisfactory wave elimination effect of single floating box floating breakwater, achieve simple structure, increase wave absorption capacity, reduce The effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

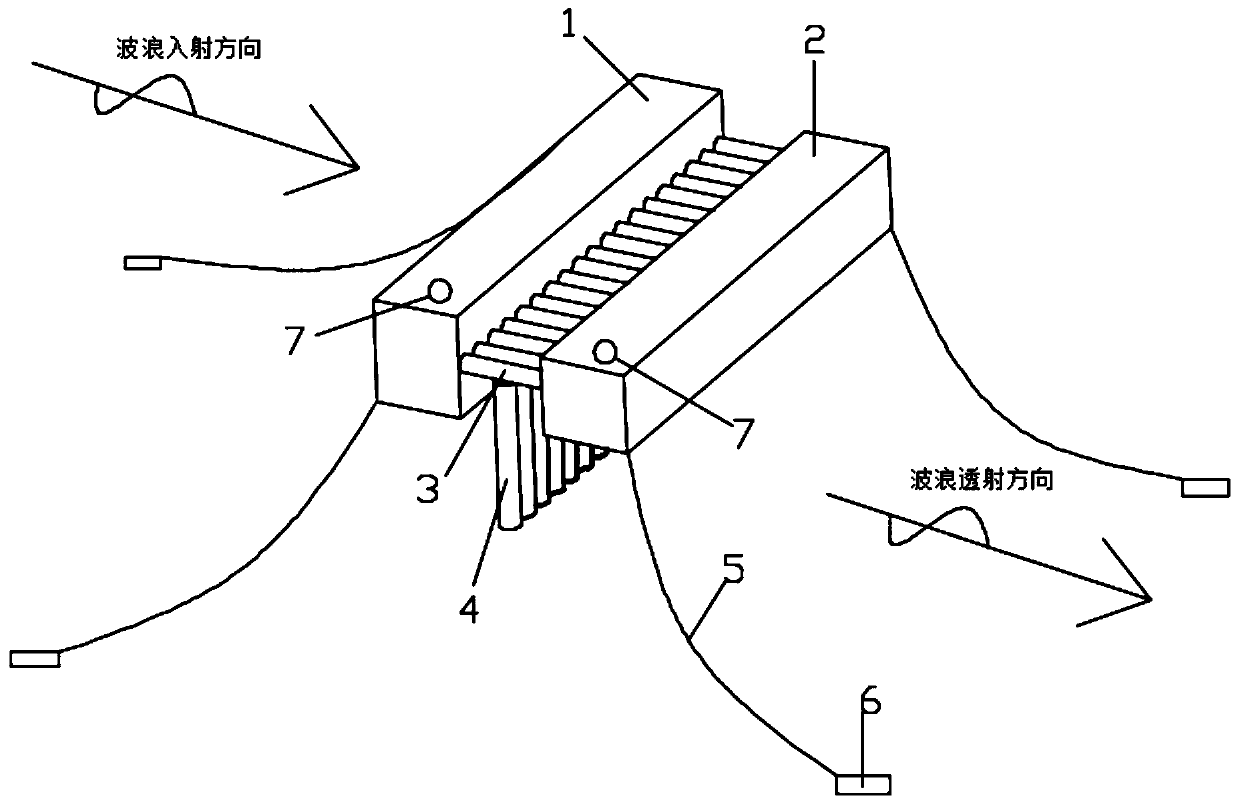

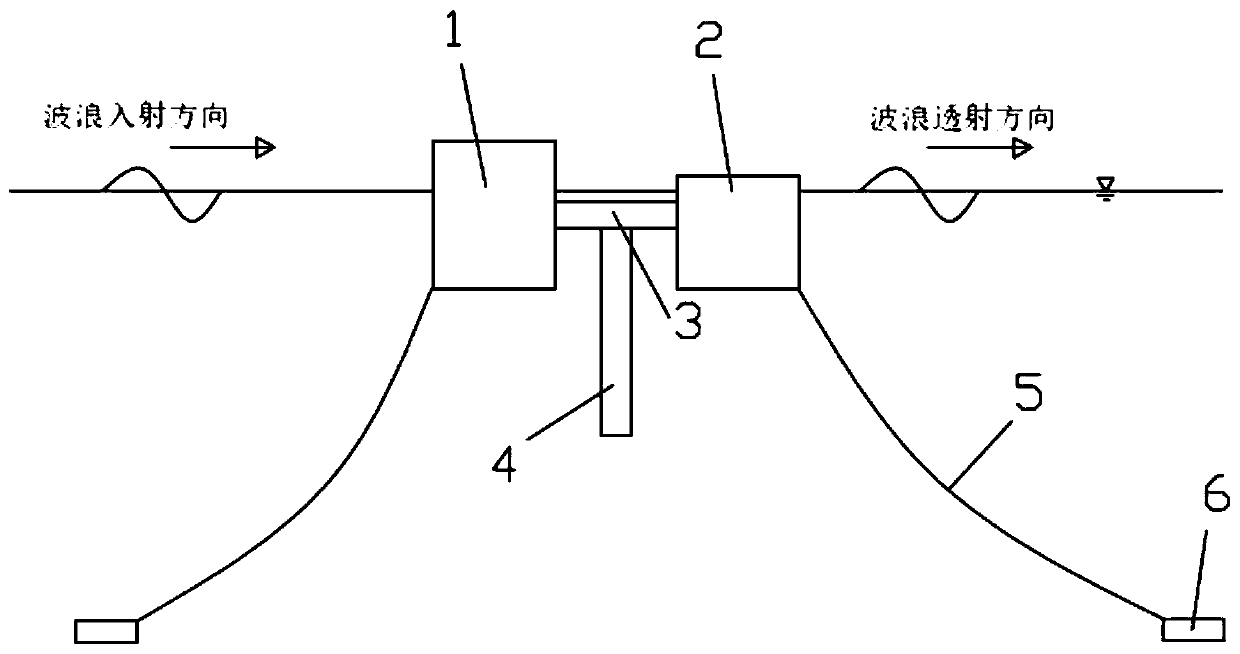

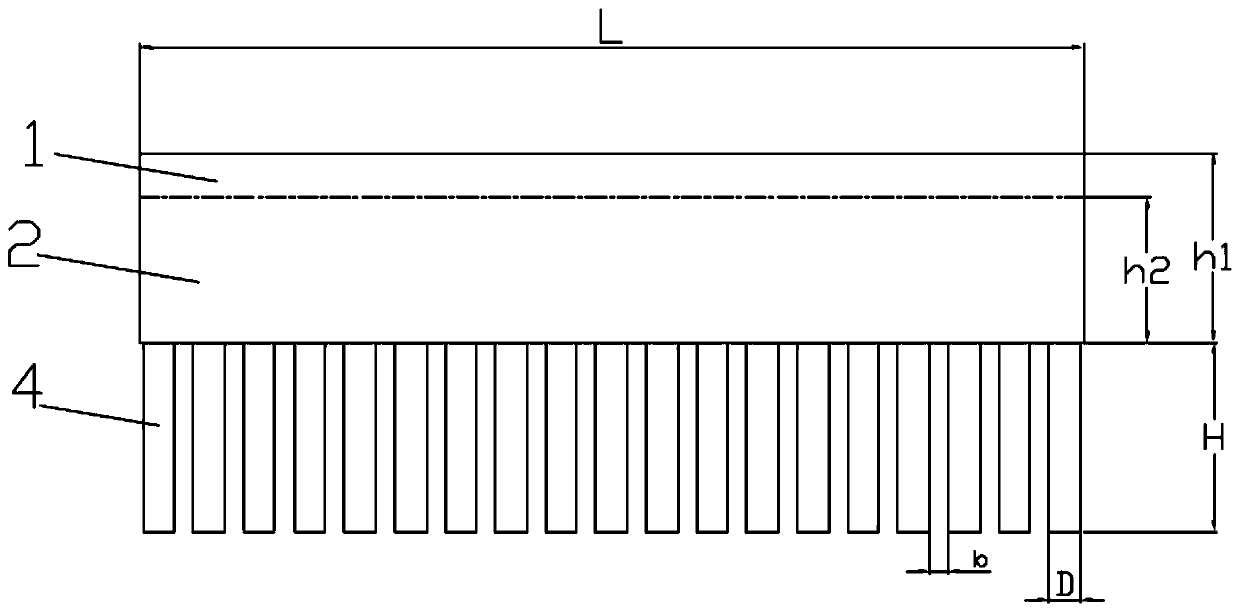

[0039] The present invention provides an asymmetric double buoy type floating breakwater, which includes a front buoy 1, a rear buoy 2, a connecting piece 3 and an energy dissipating piece 4, the front buoy 1 and the rear buoy 2 are fixedly connected as a whole through the connecting piece 3; The energy dissipation element 4 is vertically arranged on the connection element 3, and the energy dissipation element 4 is fixedly connected with the connection element 3. The energy dissipation element 4 is used to disturb the wave movement, and the energy dissipation element 4 dissipates the energy of the wave through friction and turbulence between the water body and the water body. surface energy.

[0040] The mooring device includes an anchor chain 5 and a sinker 6, one end of the anchor chain 5 is fixedly connected to the sinker 6, the other end of the anchor chain 5 is fixedly connected to the front buoy 1 and the rear buoy 2 respectively, and the anchor chain arranged on the same...

Embodiment 2

[0051] This embodiment is slightly modified on the basis of the above-mentioned embodiment 1, such as Figure 5 As shown, the anti-collision device 8 is symmetrically arranged on the outside of the front buoy 1 and the rear buoy 2. The anti-collision device 8 includes an anti-corrosion layer 801, a front stressed steel plate layer 802, a stressed cavity 803, a spring 804, and a rear stressed steel plate Layer 805, flexible buffer layer 806.

[0052] Specifically, the internal structure of the anti-collision device 8 is as follows: Image 6 As shown, the anti-corrosion layer 801 is arranged on the outermost side of the anti-collision device 8, that is, the anti-corrosion layer 801 is arranged on the outer side of the front stressed steel plate layer 802 and the upper side and the lower side of the stressed chamber 803 to prevent seawater from corroding, and the front stressed steel plate The space between the layer 802 and the rear stressed steel plate layer 805 constitutes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com