High-capacity anti-sliding system and construction method

A systematic and capable technology, applied in construction, excavation, infrastructure engineering, etc., can solve the problems of large manual cross-hole work, difficult maintenance of cast-in-place concrete, and large manual work, so as to save concrete consumption and save concrete The effect of saving the amount and saving the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

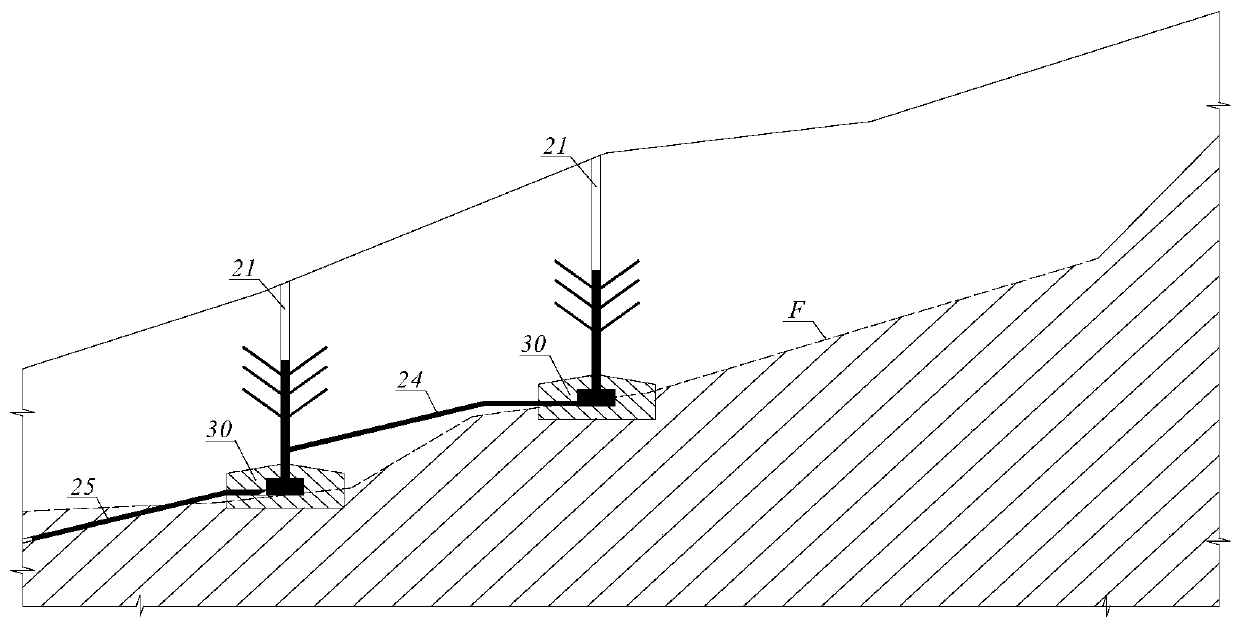

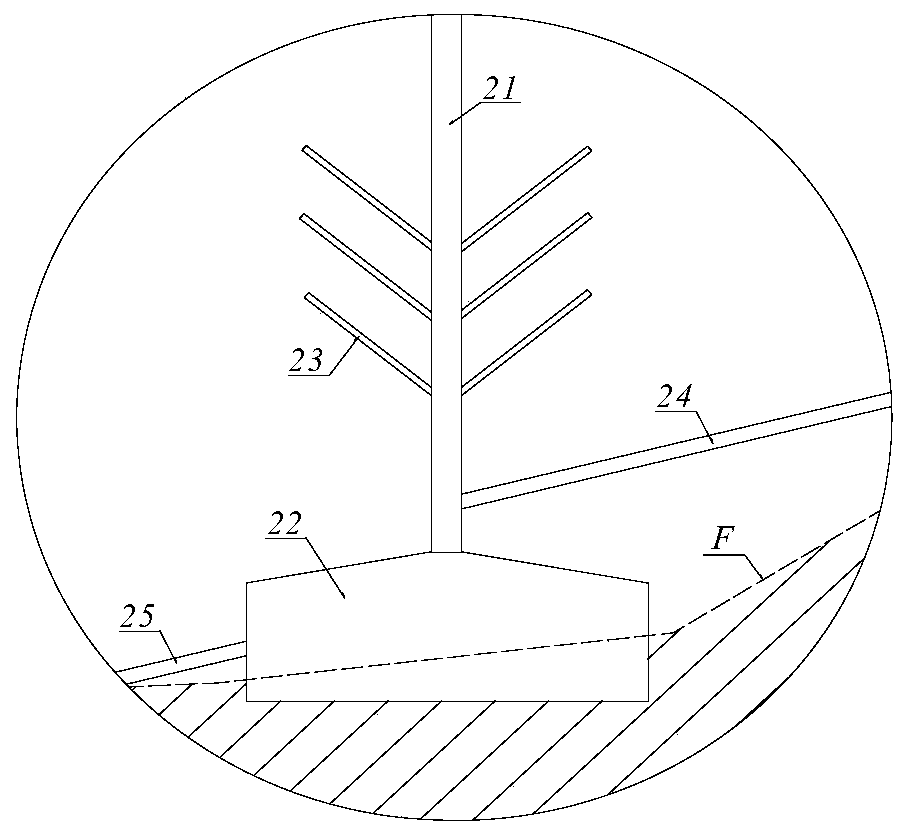

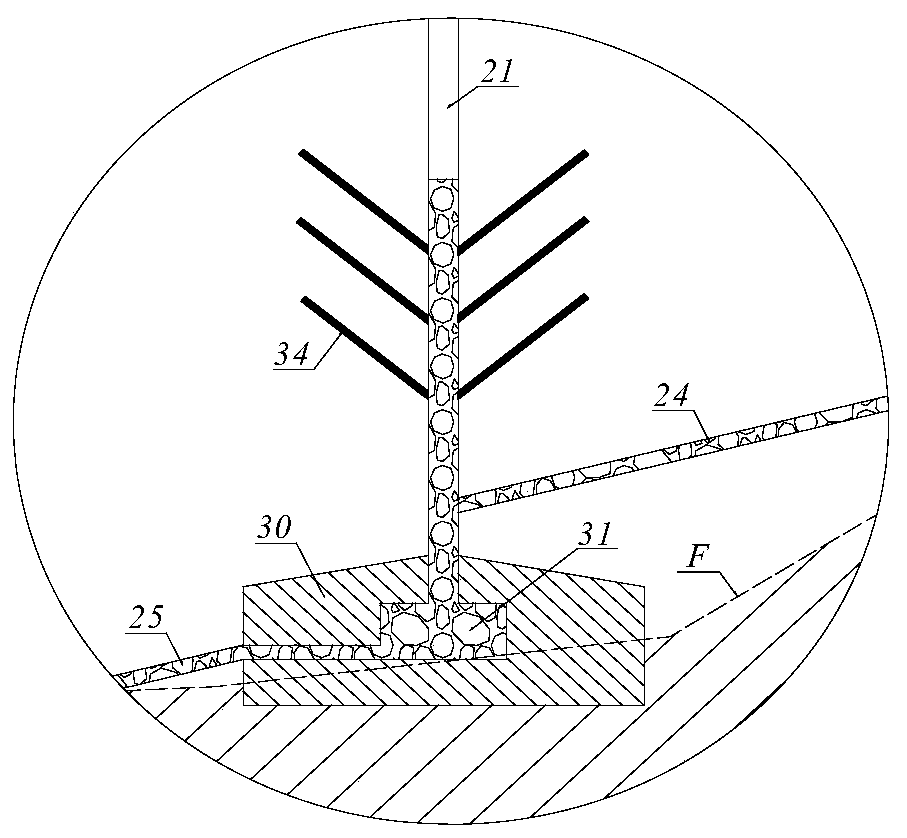

[0031] refer to figure 1 , image 3 and Figure 4 , Fig. 6, the large-capacity anti-slip system of the present invention includes longitudinally and transversely spaced anti-slip bodies in rows, and the anti-slip bodies are constructed by relying on the construction chamber 22, and the construction chamber 22 is located on the sliding belt F, or is located adjacent to In the sliding body 11 of the sliding belt F, each anti-sliding body passes through the sliding belt F by the sliding body 11 and enters the sliding bed 10 . Instead of the support mode of the traditional anti-slide piles completely resisting the sliding force, the anti-slide body directly reinforces the sliding belt in the landslide, so as to prevent the anti-slide body from bearing excessive sliding body thrust. According to the degree of resistance of the anti-sliding body in the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com