Welding-free structure of PTFE heat exchanger

A welding-free, heat exchanger technology, applied in heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low bonding strength, difficulty in achieving load bearing capacity, etc. Simple and convenient installation, saving installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

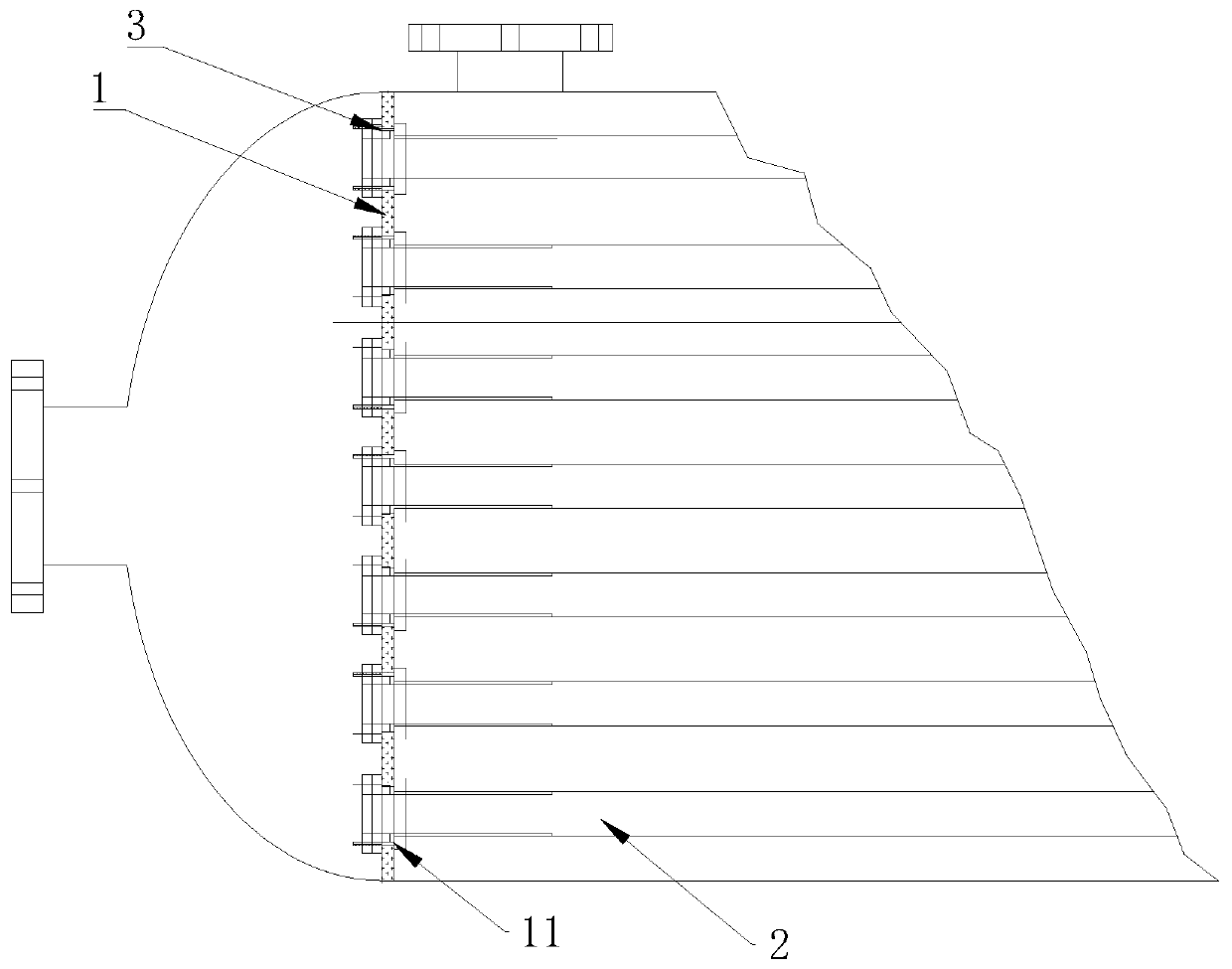

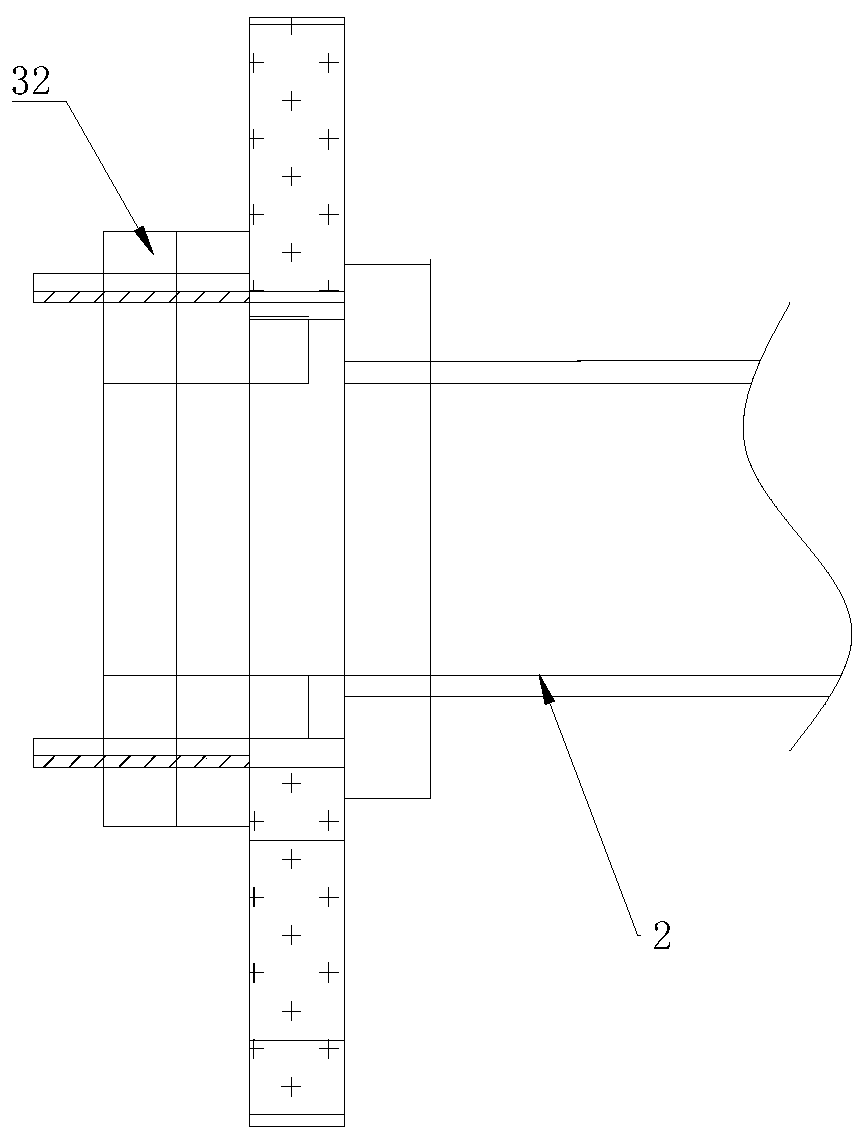

[0037] Embodiment 1: A welding-free structure of a PTFE heat exchanger, including a tube sheet and heat exchange tubes passing through the tube sheet. The heat exchange tube is made of PTFE material, and the tube sheet is set as a circular plate. Hole, the pipe body passes through the receiving hole. The diameter of the receiving hole is equal to the inner diameter of the nut.

[0038] A quick-connect joint is detachably connected between two adjacent sections of heat-exchange tubes, and the connection position between the quick-connect joint and the heat-exchange tube is located at the tube sheet.

[0039] The quick connector includes a joint for being sleeved on the heat exchange tube, and a locking piece for limiting the joint to the tube sheet, and the locking piece includes a nut installed at the end of the heat exchange tube.

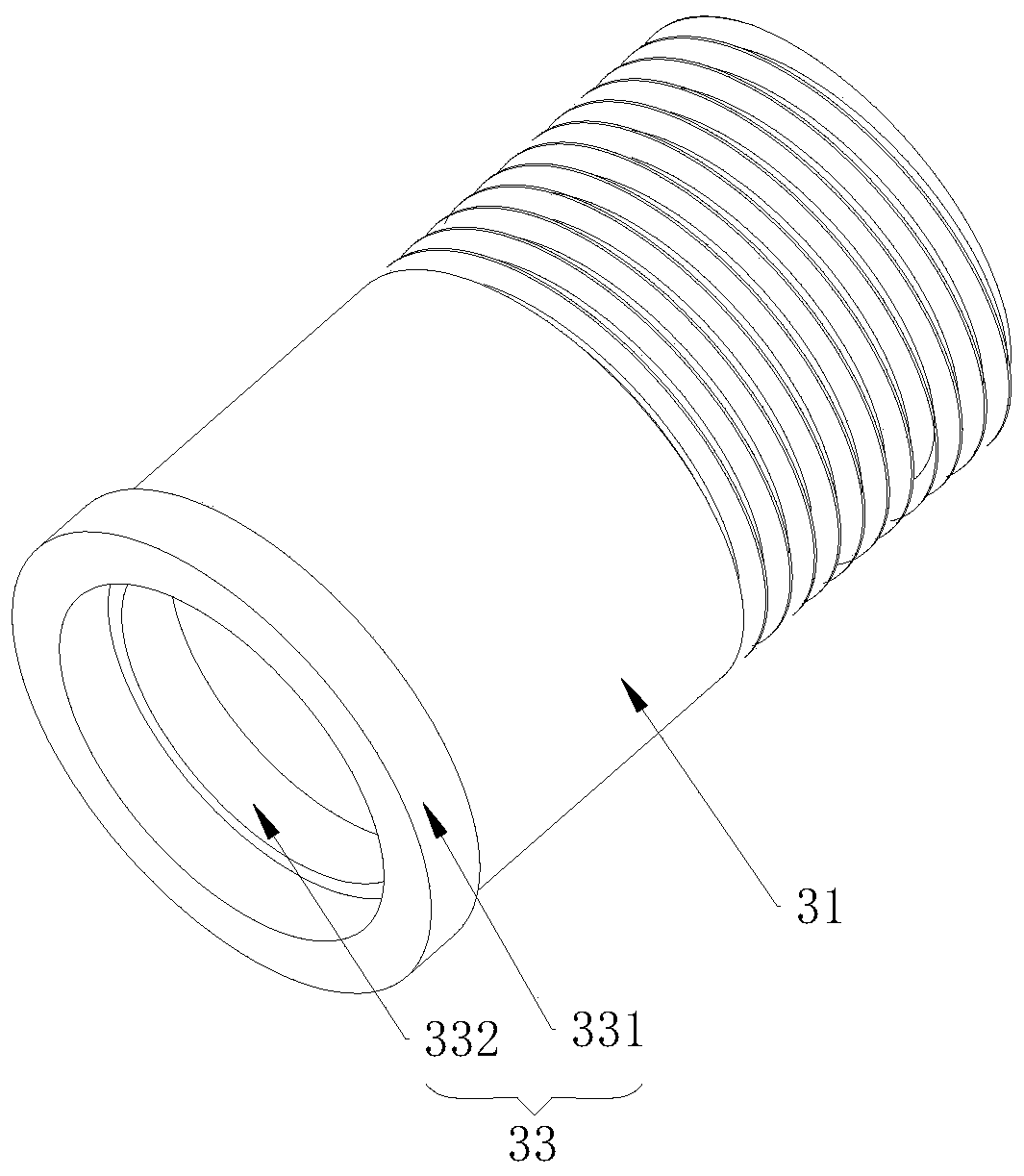

[0040] Wherein, the union includes a cylindrical pipe body, and a platform is provided at the end of the pipe body. The pipe body is set as a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com