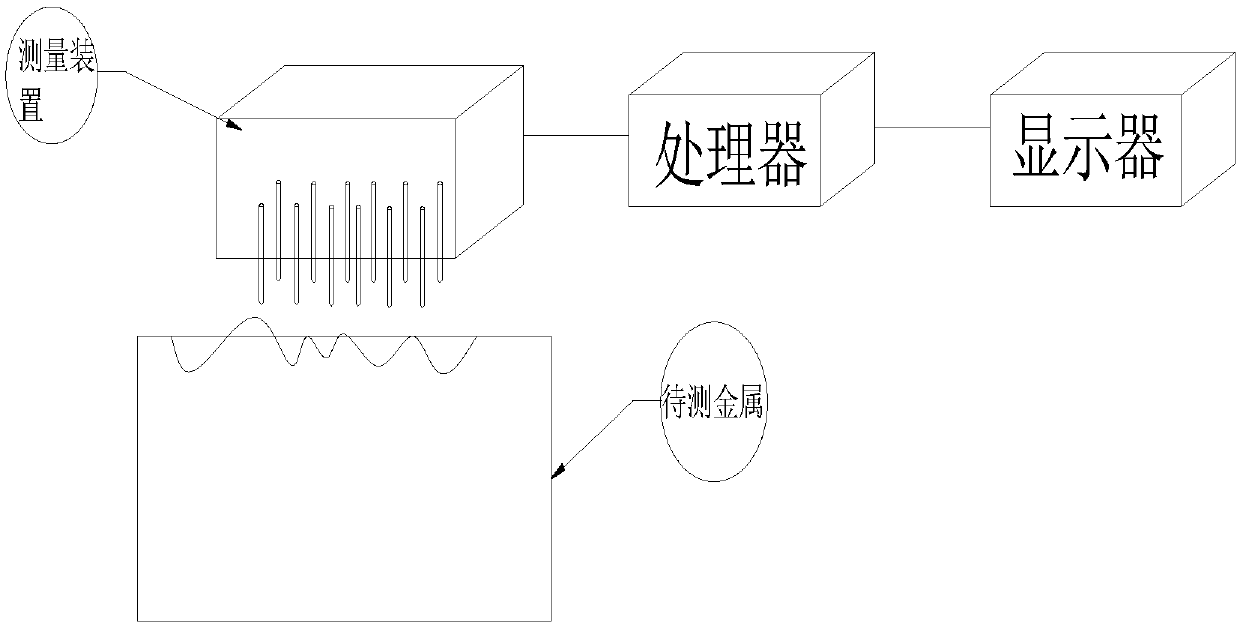

Metal abrasion loss measurement method and implementation device

A metal wear and quantity measurement technology, which is applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of metal wear measurement difficulties, and achieve the effects of wide practicability, stable signals, and easy collection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

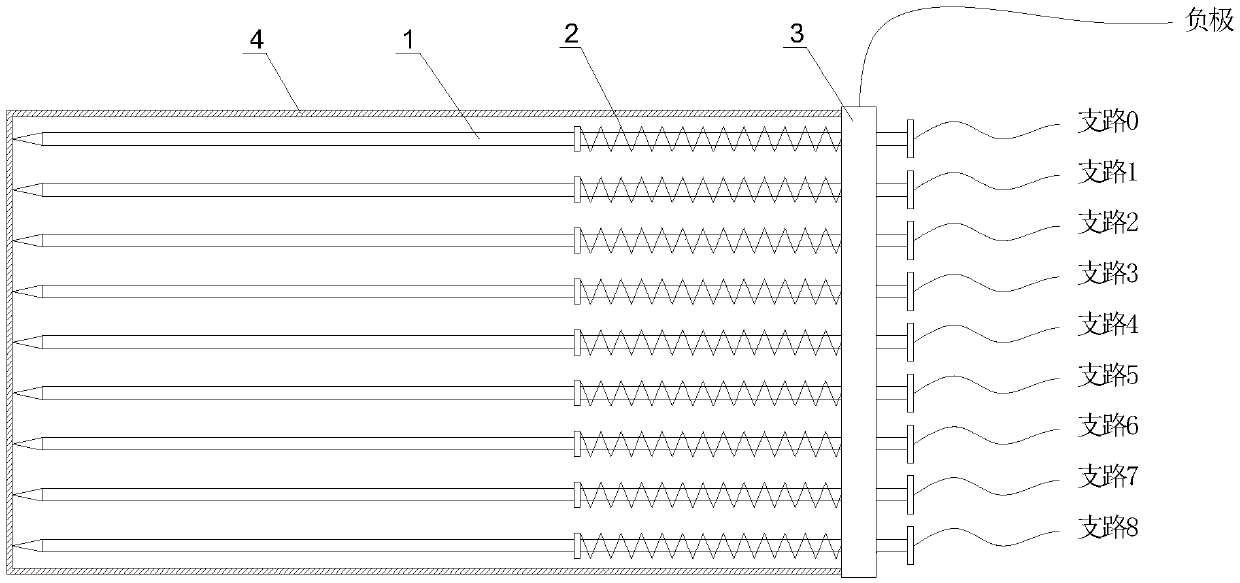

[0014] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 2 As shown, the specific number of probes 1 is determined according to the actual situation, and must be one row or several parallel rows, and the more the number of rows, the higher the measurement accuracy. The length of each row depends on the width of the metal wear position. It is necessary to ensure that a part of each row of probes is located in the groove formed after the metal wear, while the other part is located on both sides of the wear groove.

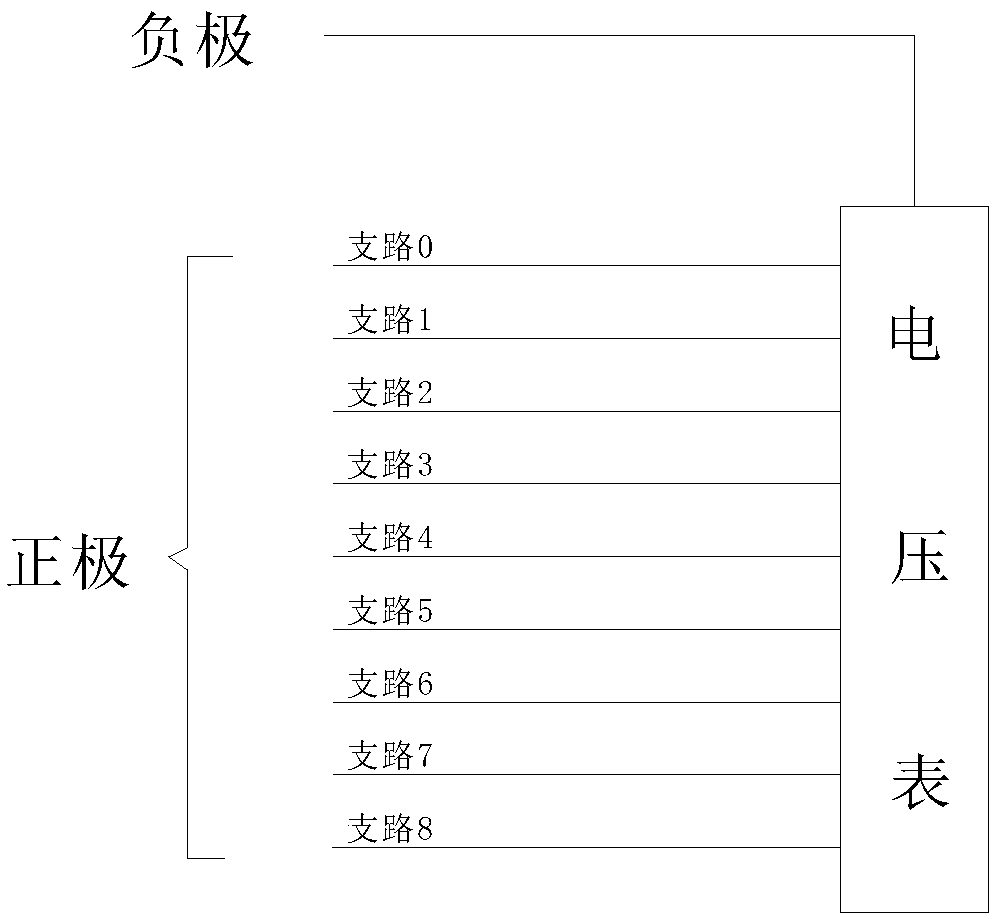

[0016] Each probe is made of a special material, which has its own resistance, and the resistance value changes linearly with the change of the length under the condition of constant cross-sectional area. These probes are all fixed in corresponding holes on the metal plate 3, and each probe end is connected with a wire. And the spring 2 can ensure that each probe can return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com